Cloud-based applications promise to deliver benefits for industrial applications, but implementation challenges exist.

Cloud computing is becoming increasingly attractive for business and personal applications where its low cost solutions and fast deployment help companies and individuals save time and money.

Many people already use the cloud for document management, data backup, Web mail, and music and video storage. These applications are free or very inexpensive, and reliable enough for the most part.

More businesses are taking advantage of cloud-based applications to help streamline their operations and reduce costs. As reported in the Industrial Networking Q2 2012 cover story “The Cloud is Coming,” a recent report from The Economist Intelligence Unit and IBM indicates that 90 percent of America corporations plan to use the cloud in their organization by 2015.

Businesses are using the cloud in similar ways to individuals for data storage, Web mail and large data file transfers like software downloads. Some companies have gone to the next step by outsourcing entire functions, switching to a software-as-a-service (SaaS) model in which the cloud provider hosts an application accessed via a thin client or a Web browser. An example of this is a customer relationship management service, such as Salesforce.com, in which users pay a monthly fee for the service, as an alternative to in-house software and databases.

Real Benefits

It’s easy to be skeptical about the benefits of cloud computing as many have become immune to the hype about the latest technologies. However, the cloud really does provide significant benefits, especially in terms of cost reductions when compared with in-house systems.

For example, data storage and backup have traditionally been the realm of in-house IT departments that install and manage the software, servers, etc. However, many businesses are choosing cloud providers for data storage because economies of scale result in extremely low fees. For this and other applications, using a cloud provider eliminates or dramatically reduces labor, purchasing and maintenance costs associated with implementing an in-house solution.

Another important benefit to cloud computing is faster deployment and upgrades. Since the cloud provider handles all the deployment and upgrades, a SaaS application can be deployed in as little as an hour or two, instead of the weeks or even months required for an in-house solution.

The cloud, as a remote application, often simplifies and expands remote data access. No longer do companies need to maintain a virtual private network (VPN) to enable access to applications.

The Cloud for Industrial Manufacturing

While cloud computing isn’t as common in the industrial automation world, its benefits are making it more attractive for industrial applications. However, simply duplicating the same type of applications and architecture used for other businesses isn’t the best way to introduce cloud computing to industrial manufacturing, due to the unique needs of the automation sector.

Industrial applications rely heavily on real-time data, and at present it’s difficult to see industrial users depending on cloud computing to deliver this type of information. Nevertheless, industrial manufacturers will most likely follow the lead of other businesses and use the cloud for tasks that support manufacturing, particularly data storage and remote access.

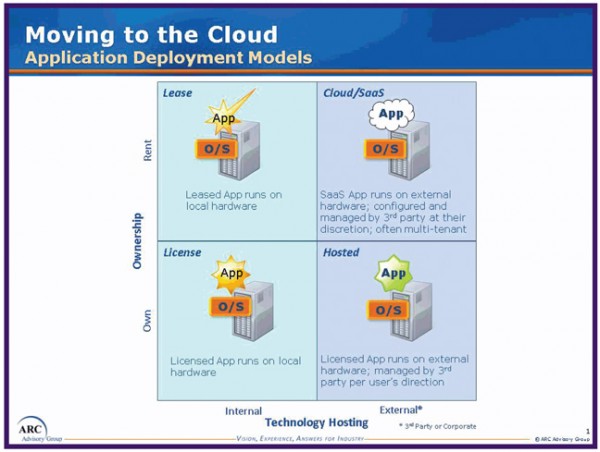

Image 1: ARC, page 4. Cloud-based can be purchased as hosting services for a user application or as software as a service. Diagram supplied by ARC Advisory Group.

In general, there are two methods for performing manufacturing related tasks. Using the first and currently most common method, the cloud will host a service provided to the manufacturer by a system integrator or an automation vendor. This service will then be sold to the manufacturer, typically on a monthly subscription basis. The second method involves manufacturers, using hardware and other associated infrastructure provided by others, to run their own applications in the cloud.

Regardless of the method selected, two-way access to the automation controllers isn’t typically provided. However, this too is changing as system integrators are working with OEMs to design cloud-based access and control systems with automated two-way communications.

For example, in the event of an alarm, the controller could send an alert to a user via the cloud. The user could acknowledge the alarm, and then send a command to the controller to correct the issue.

This two-way access via the cloud will be a significant change from today’s models. In some instances, the cloud would become part of the critical path between the end user making a decision and the control system receiving it. In the same way when control systems first moved to non-proprietary networks, these developments are almost certain to involve some controversy.

Considerations for Cloud Computing

Many industrial companies’ data contains intellectual property they wish to protect from their competitors. Although cloud providers offer many security features and devices, it can still seem risky to send data into the cloud where others may be able to access it.

Reliability is also a concern for industrial manufacturers who have traditionally only used in-house systems for their production and manufacturing processes. They may fear relying on Internet connectivity and outside service suppliers over whom they have no direct control.

While data stored in the cloud is protected by a variety of security measures, storing data outside the plant does create a new type of vulnerability. The cloud provider should have much stronger security and encryption in place, with 24/7 support to stop unauthorized access, than a typical in-house IT department. Data security is the meat and potatoes of cloud providers, giving them an incentive to be informed of the latest security threats, as well as to implement the latest security measures.

However, the collective data in the cloud is much more extensive and valuable than the data in a single industrial company, which makes it a more attractive target to hackers. Applications and data may face increased risk from network threats that were previously defended against at the perimeter of the organization’s intranet, as well as from new threats that target exposed interfaces.

A configuration or software error could accidentally allow access to organizational data and resources to other subscribers. An attacker could also pose as a subscriber to exploit vulnerabilities from within the cloud environment to gain unauthorized access. Botnets have also been used to launch a denial of service attack against the infrastructure of a cloud provider.

Having to share an infrastructure with unknown outside parties can be a major drawback for some applications; it demands a high level of assurance of the strength of the security mechanisms used by the cloud provider. Users must also have confidence in the long-term stability of the cloud provider because of the near total dependency on the selected cloud provider, and this dependency increases with the length of time the provider is used.

For example, a company may use a cloud provider for manufacturing data storage. The selected provider would control the data and be free to raise prices at any time. If the manufacturer decided to switch to another provider, it would require cooperation from the cloud provider to transfer the data.

While regulations exist in the U.S. and other countries that require transfer of money and/or data from one provider to another for the financial services and telecommunications industries, no such regulations exist for the cloud yet. On the other hand, it would be unlikely for future regulations not to implement similar requirements.

Outside of data security, the biggest concern among industrial users is the dependency on an Internet connection to access cloud data. Alternate access paths are typically provided by cloud providers, but users may see internal networks as more reliable than any practical number of Internet connections.

Making the Leap

While remote access is the most obvious draw for the cloud in terms of functionality, asset management is very appealing and seems to be particularly well suited to the cloud. Improving asset utilization is important to manufacturers, but in-house deployment requires large investments in software, servers, networks—as well as IT and asset management experts.

Asset management through a cloud-based model could facilitate virtually instant deployment with very low up-front costs. A manufacturer would only have to provide a high-speed two-way data connection to the control and information system, and then the vendor could immediately begin collecting and analyzing data.

After analyzing the data, the vendor could provide specific recommendations for improving asset utilization. For a monthly fee on a relatively short-term basis, this application would minimize some of the concerns about being locked into a vendor or contract.

Manufacturing stands to benefit from the cloud, and new applications are being developed on a continuing basis. However, it’s unlikely cloud computing will be used for real-time control any time in the foreseeable future.

Instead, the cloud is more likely to provide services associated with manufacturing, such as remote access and data storage.

As with any new technology or application, concerns exists in regards to reliability and control. Standards and regulations need to be established, and most likely will be as the market grows.As the technology matures for the industrial automation market, it’s a good bet that cloud use will become more widespread among manufacturers who will benefit from its cost savings and faster deployment.

By Christine Lesher

Originally Posted: June 1, 2012