Nestled along the Chatooga River, in Trion, Georgia, Mount Vernon Mills is one of the largest and oldest textile mills in the United States. Its long history dates back to 1845. The initial 5,000 square foot two-story mill had 40 employees and produced 5-lb. bunches of yarn to sell to local merchants from wagons.

Over the next 160 plus years, the mill survived General Sherman’s march through Atlanta, a fire in 1875, bankruptcy in 1912, two World Wars, the fight to become unionized, and a major flood in 1990. Through all of this, the mill has continually expanded, renovated, and modified in order to tailor its end products to change with the times. The mill has produced many different products over the years, including fabric used for military uniforms, crop sacks, sheeting, shirting and even gloves.

In 1971, the decision was made for this Trion, Georgia, plant to produce denim. This turned out to be one of the best decisions in the mill’s history. By installing new equipment, the plant rode the wave of growth in the denim industry. By 1976, Mount Vernon Mills had over 1,100 looms producing denim. The company continued to grow, but nearly experienced disaster when the “Hundred Year Flood” hit Trion in 1990. The company spent the next several years modernizing its plant with state-of-the-art machines to gear up denim production.

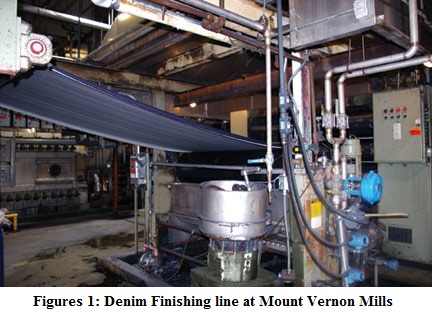

After its latest round of renovations, the mill now operates with state-of-the-art machines in over one million square feet of manufacturing space. Denim from Mount Vernon Mills is woven and finished for sale to many major manufacturers across the country, such as Wrangler™ and Lee ™. Mount Vernon is now the third largest producer of denim in the United States. (See Figures 1 & 2)

After its latest round of renovations, the mill now operates with state-of-the-art machines in over one million square feet of manufacturing space. Denim from Mount Vernon Mills is woven and finished for sale to many major manufacturers across the country, such as Wrangler™ and Lee ™. Mount Vernon is now the third largest producer of denim in the United States. (See Figures 1 & 2)

Over the years, the company has endeavored to continually upgrade machines and technologies, and the past few years have been no exception. On some of the finishing ranges and re-beamers, control systems still worked, but finding replacement parts had become more difficult, thus making it harder to give operators features and functions they wanted. Even modest changes and modifications were difficult based on the age of the control system. Late in 2006, the mill decided to embark on upgrades for re-beamers and one of its finishing lines.

The task of replacing the control system for the finishing line, a very large multi-motor machine, seemed daunting. All the motors have to work together and are self-adjusting, with dancer position sensors which send signals back to a PLC system. The PLC system automatically adjusts motor speeds to keep everything running together.

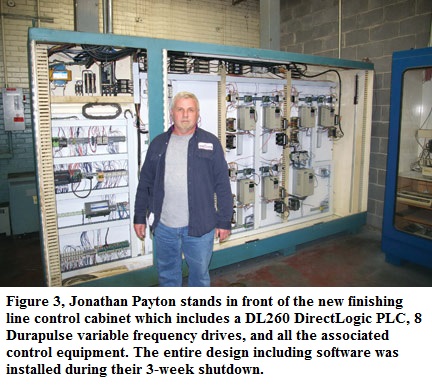

Because of the machines’ size and complexity, the mill sought bids for the work. When job bids came back with costs far exceeding budget, the decision was made to use AutomationDirect components, and do the whole project in-house. To save time, new backplanes were purchased to bolt onto the old cabinet back so they could be assembled and tested before installing in the machine. This task would be performed in the system designers’ spare time over a period of three months. They ended up having only three weeks to build and no time for testing. Electricians were finished mounting the motors and drives before programmers had the software completed.

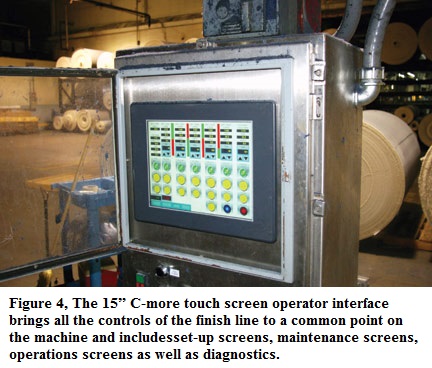

The old finishing line was powered by DC drives with field regulators. The new system has been upgraded to AutomationDirect’s Durapulse AC Drives all networked via Ethernet to a DL-260 DirectLOGIC PLC System. A 15” C-more touchscreen operator panel was chosen to replace the main operator console. The mill purchased, installed and programmed the entire system within the three weeks allotted. All HMI and PLC programming was performed in-house, and AutomationDirect’s telephone technical support staff answered questions when problems arose. (See Figures 3 & 4)The solution has been a great success. The mill saved nearly $40,000 compared to the bids received, and now the control system is now largely software based. Operators have much more control of the machine, including setup parameters of dry cans and dancers, line speeds, trimming capabilities, as well as some fault indication and maintenance screens. New functions or features can also be added, as they continually refine the process to improve productivity.

The old finishing line was powered by DC drives with field regulators. The new system has been upgraded to AutomationDirect’s Durapulse AC Drives all networked via Ethernet to a DL-260 DirectLOGIC PLC System. A 15” C-more touchscreen operator panel was chosen to replace the main operator console. The mill purchased, installed and programmed the entire system within the three weeks allotted. All HMI and PLC programming was performed in-house, and AutomationDirect’s telephone technical support staff answered questions when problems arose. (See Figures 3 & 4)The solution has been a great success. The mill saved nearly $40,000 compared to the bids received, and now the control system is now largely software based. Operators have much more control of the machine, including setup parameters of dry cans and dancers, line speeds, trimming capabilities, as well as some fault indication and maintenance screens. New functions or features can also be added, as they continually refine the process to improve productivity.

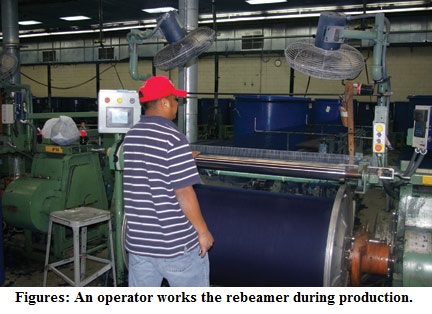

On a second project, Mount Vernon retrofitted the legacy control system for a re-beamer in order to improve performance and flexibility. The re-beamer is a speed-controlled center winder which winds yarn from several section beams onto a single-loom beam prior to weaving. The winding speed requires constant adjustment to maintain a constant yarn velocity.

The original control design for the re-beamer featured manual controls (pushbuttons, pilot lights, and meters) on the operator station and a DC drive to wind the spool. With dozens of these machines throughout the facility, not only was it more difficult to obtain replacement parts for outdated equipment, but it was also difficult to make changes to the machines, operator interfaces, and control system.

The original control design for the re-beamer featured manual controls (pushbuttons, pilot lights, and meters) on the operator station and a DC drive to wind the spool. With dozens of these machines throughout the facility, not only was it more difficult to obtain replacement parts for outdated equipment, but it was also difficult to make changes to the machines, operator interfaces, and control system.

The re-beamer is now equipped with a DirectLOGIC DL06 PLC, a Durapulse AC variable frequency drive, a proximity sensor and a C-more operator interface panel. Because the outsourced PLC program never worked correctly, it was scrapped and rewritten in-house. This allowed placing more parameters and adjustments at the operators’ fingertips. Additionally, operators continually suggest improvements to the process or machine, and now system programmers are able to act on their inputs, and use the software based control system to streamline the process. (See Figures 5 & 6)

Mount Vernon Mills continues to retrofit additional control systems as time and budgets permit. The control solutions put together with AutomationDirect equipment have provided quite a cost savings over alternative solutions on the initial purchase. Changing the controls to software-based HMI and controls also provides the flexibility to easily make changes and improvements to the line.

Control engineers at Mount Vernon Mills agree the free technical support from AutomationDirect is the best they have ever used. They also feel the quality and service of AutomationDirect products to be comparable to more costly products purchased from previous suppliers.

By Jonathon Payton

Mount Vernon Mills

Originally Published: Sept. 1, 2009