Check out this Q&A about all things pneumatic cylinders!

Q. What pneumatic cylinders and accessories are available from AutomationDirect?

A. The NITRA A-Series non-repairable stainless steel round body cylinders includes bore sizes from 7/16” to 2” and stroke lengths from 1/2” to 18” to meet a broad range of applications. These high quality cylinders are constructed with stainless steel bodies and double rolled-in high strength aluminum end caps with full flow ports. To minimize friction, the inside of the cylinder body is polished to a mirror finish and all cylinders are pre-lubricated for optimum performance and long, reliable life. The high strength aluminum alloy piston is securely threaded, sealed and riveted to a piston rod that is ground and roller burnished 303 stainless steel (7/16” and 9/16” bores) or ground and polished high strength carbon steel ( 3/4” – 2” bores) with roll-formed threads for exceptional strength. Low friction wear compensating Buna N U-cup rod and piston seals, oil impregnated rod guide bushing (except 7/16” and 9/16” bores), and end caps with slots all combine for smooth breakaway even at low pressures.

NITRA Pneumatic Cylinder Features

• Interchangeable with other common brands of round body cylinders

• Available bore sizes: 7/16”, 9/16”, 3/4”, 7/8”, 1-1/16”, 1-1/4”, 1- 1/2”, 2”

• Excellent selection of stroke lengths from ½” to 18”

• Single-acting (spring return) and double-acting models

• Nose, pivot and double-end mounting options and accessories

• Type 304 stainless steel body with high-strength aluminum alloy end caps

• Pre-lubricated for long, maintenance-free performance

• 250 psi operating pressure

• Models available with magnetic piston for position indication

Other pneumatic components available from AutomationDirect include cylinder position switches, nylon and polyurethane tubing, push-to-connect fittings, and flow control valves.

Q. What is the difference between double acting and single acting spring return cylinders?

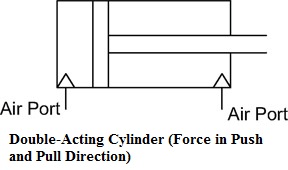

A. Double acting cylinders have two air connection ports. One of the ports will extend the cylinder rod and provide power in the “push” direction and the other port will retract the rod and provide power in the “pull” direction. Double acting cylinders are controlled by 4-way directional control valves and are a better choice when it is necessary to control cylinder speed.

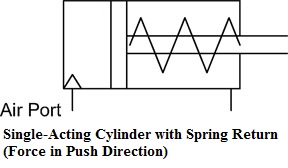

Single acting spring return cylinders have one air connection port to extend the cylinder rod and provide power in the “push” direction. An internal spring retracts the cylinder rod in the “pull” direction. With only a spring (no air pressure) to retract the cylinder rod, very little power is available in the “pull” direction. Single acting cylinders use about one-half as much air as double acting cylinders and are operated by 3-way valves. (Figure 1)

Q. What cylinder bore size should be used for my application?

A. Follow these steps to determine an appropriate cylinder bore size:

1. Evaluate the force (in pounds) needed to move the maximum load. To account for friction add another 25% as a rule of thumb.

2. Determine the minimum air pressure (in psi) that will be avail able at the cylinder. Keep in mind the available pressure at the cylinder will likely be less than the system pressure due to pressure drops in the air lines, fittings, valves, etc.

3. The following formula is used to calculate the required area of a cylinder piston:

A = F / P

F is force in pounds

P is pressure in psi

A is area of the cylinder piston in square inches

Using the force from Step 1 and the pressure from Step 2 calculate the minimum piston area required and select a cylinder bore size with a piston area equal to or greater than the calculated value from the table below.

| NITRA Cylinder Piston Area (sq ins) 0.15 0.25 0.4 0.6 0.9 1.2 1.7 3.1 | ||||||||

| NITRA Cylinder Bore Size (ins) 7/16 9/16 3/4 7/8 1-1/16 1-1/4 1-1/2 2 |

Q. What can be done to get more power from a cylinder?

A. Based on the equation Force = Area * Pressure, simply increasing the air pressure to the cylinder within its specified limits will increase the available force. Alternatively, changing to a larger bore size cylinder will also result in greater available force.

Q. How can cylinder speed be controlled?

A. Double acting cylinders are the best choice when it is necessary to control cylinder actuation speed. Install adjustable meter-out flow control valves (speed controllers) on each cylinder port to control the air leaving the cylinder. Controlling the incoming air to a cylinder instead of the outgoing air can cause erratic movement during the cylinder rod’s stroke. NITRA FVS series adjustable meter-out elbow flow control valves are ideal for controlling cylinder speed. (Figure 3)

Q. What are possible causes of erratic cylinder rod movement during its stroke?

A. Possible causes include:

1. Input air pressure to the cylinder is too low for the load being moved

2. Cylinder bore size is too small for the load being moved

3. Excessive side loading on the cylinder rod

4. Controlling cylinder speed with flow control valves (speed controllers) to control the incoming air to the cylinder instead of the leaving air.

5. Flow control valves are set too low

6. An absence of lubrication

7. Damaged or dented cylinder bore

Q. What is cylinder side loading?

A. Side loading occurs when the cylinder mounting and piston rod connection are misaligned or when a load is placed on the cylinder piston rod without guidance or support. Side loading creates excessive wear on the cylinder piston, piston rod, rod bearings, and seals which leads to premature cylinder failure. To minimize the adverse effects of cylinder side loading for rigidly mounted cylinders, be sure the object being moved is in exact alignment with the piston rod. Using guide rails to keep the load being moved in alignment may be helpful. For pivot mount cylinders use a rod eye or rod clevis on the piston rod otherwise it will function like a rigid mount cylinder. Finally, don’t use the full stroke especially with long cylinder rods. Using a piston stop short of full stroke will make the cylinder more rigid and extend bearing life.

Q. How can the position of the cylinder piston be sensed when it reaches its end of stroke limits?

A. NITRA CPS series pneumatic position switches offer a robust interface between pneumatic actuators and electrical control systems. Using state-of-the-art AMR magnetic sensing technology, these switches are designed for use with pneumatic cylinders that have a magnet incorporated in the cylinder piston. They can be used to provide a switched output for cylinder position indication, cycle count or to confirm operation.

The NITRA CPS series is available in 3-wire DC, PNP normally open, PNP normally closed, and NPN normally open electronic solid state switch configurations with either an M8 wiring connector or wire leads. Designed to provide a low profile, flush installation on cylinders with T-slot channels, these switches are also easily mounted on round body cylinders using CPSB series mounting bands. Integral LED indication provides switch status for speedy switch positioning and troubleshooting.

Pre-tested for use with NITRA pneumatic cylinders with magnetic piston option, the CPS series is also suitable for use with other brands of cylinders with magnetic pistons. (Figure 4)

By George Tsakir

Product Manager, Process and Fluid Power

Originally Published: Sept. 1, 2009