Pressure switches are commonly used in a wide variety of industrial and commercial applications. To meet the varying demands of these applications, numerous pressure switch designs are available. The key to selecting the best pressure switch for your application is understanding the differences in pressure switch designs. Read on to learn more about pressure switch basics

Pressure Switch Definition

A pressure switch is simply a device capable of detecting a pressure change and, at a predetermined pressure, opening or closing an electrical switch.

Pressure switches are usually classified as either electromechanical or solid state.

Electromechanical pressure switches have a sensing element which responds to changes in pressure and mechanically operates a snap-acting switch in response to the pressure changes. Different types of sensing technologies are used in the design of electromechanical pressure switches. Diaphragm switches use an elastomeric or weld-sealed metal diaphragm which deflects with pressure changes; they act directly, or via a push-rod, on a snap-acting switch.

With a bellows or bourdon tube switch, the movement of the bellows, or sealed metal bourdon tube, is caused by pressure changes; this movement mechanically operates a snap-acting switch.

A piston switch design uses an O-ring sealed piston that moves in response to pressure changes, and directly or via a push-rod, actuates the electrical snap-acting switch.

Solid state pressure switches use the same technology found in analog pressure transmitters to sense changes in pressure. A weld-sealed metal diaphragm or O-ring sealed ceramic diaphragm with a piezoresistive strain gage-based sensing element is used to measure changes in pressure. Rather than harnessing the energy of the pressure changes to mechanically operate a switch (as with electromechanical pressure switches), solid state pressure switches electrically measure pressure changes and internal electronic circuitry is used to activate one or more solid state switched outputs.

Ranges, Setpoint, & Deadband

Both electromechanical and solid state pressure switches are commonly available to sense vacuum, positive pressures up to thousands of psi, and compound ranges of vacuum to positive pressure.

The predetermined point at which the pressure switch contact opens or closes is the setpoint.

Electromechanical switches are typically available with a factory setting, or with a blind adjustment capability set by the user relative to an external pressure reference such as a pressure gauge or known pressure value.

Electromechanical switch setpoints can be set to activate upon an increased or decreased pressure. Solid state switch setpoints are set either by calibrated dials, knobs, or entered digitally with a keypad and display.

When selecting the pressure range for a pressure switch, a general rule is that electromechanical setpoints should be in the middle of the operating pressure range to optimize both accuracy and switch life. With a solid state pressure switch, selecting the setpoint in the upper 25% of the operating range will provide the most accurate performance without compromising switch life.

Deadband is the difference in pressure between the switch setpoint and reset point. For example, if a pressure switch is set to activate at 100 psi on an increasing pressure, the switch will close when the pressure rises to 100 psi. When the pressure drops to the reset point of 90 psi, the switch will open. The deadband is 10 psi, the difference between the setpoint (100 psi) and the reset point (90 psi).

For electromechanical pressure switches, deadband can be adjustable but is typically a fixed value, or automatically increases linearly as the setpoint is increased through the adjustable setpoint range.

For solid state switches, the deadband is typically fully adjustable up to 100% of the full operating pressure range. As a general rule a narrow deadband is used in alarm circuits while a wider deadband is better suited for control circuit applications.

Proof and Burst Pressures

Overpressure ratings include proof and burst pressure specifications. Proof pressure is the amount of overpressure that can be applied to the pressure switch without causing damage. The pressure switch can be exposed to pressure reaching the proof pressure rating, and be expected to work properly when the pressure returns to within the rated operating pressure range.

Burst pressure is the amount of overpressure applied at which the pressure switch will certainly be damaged. Physical damage to the pressure switch may occur at any point between the proof pressure and burst pressure. Because proof pressure ratings are determined in a laboratory under controlled conditions including rate of pressure change and temperature, they should be considered a reference value. It is not uncommon for pressure switches in the field to experience pressure surges and spikes that cause damage if a switch with too low of a proof pressure rating was selected. Typically solid state switches have lower proof pressure ratings and are most sensitive to overpressure conditions. Electromechanical switches with a diaphragm generally have higher overpressure ratings than solid state switches. Piston design switches have very high overpressure ratings and are the most reliable when subjected to pressure surges or spikes, and applications where the normal working pressure is above the nominal range of the switch. If pressure surges or spikes are anticipated in an application, a pressure switch with a high proof pressure should be selected to avoid damage.

Installation of a pressure snubber can also help to dampen the effects of fast pressure spikes on a pressure switch.

Accuracy (Repeatability)

For an electromechanical pressure switch with a factory set or user adjusted setpoint relative to a known pressure reference, accuracy is a measure of the switch’s ability to repetitively operate at its adjusted setpoint under the same operating conditions. This is referred to as Repeatability in pressure switch specifications.

Because a solid state switch setpoint can be adjusted with calibrated dials, knobs, or a keypad and display, specifications will include both a setting accuracy value and a repeatability value. Pressure switches are typically available with accuracies from 0.25% to 2% and cost increases with accuracy. To avoid paying a premium for unnecessary accuracy, consider the needs of the application. An accuracy of 2% is probably sufficient for a simple alarming application, but controlling a critical process may call for a higher accuracy switch.

Chemical Compatibility

For both electromechanical and solid state pressure switches, determining the chemical compatibility of the pressure switch with the medium sensed is a critical element in the longevity of the pressure switch. Wetted parts are the parts of the pressure switch that actually come in direct contact with the medium being sensed, and their material composition is identified in pressure switch specifications. The wetted parts will include the pressure sensing port of the switch, the diaphragm, bellows, bourdon tube, or piston and any O-ring seals.

Chemical resistance charts and databases are readily available on the Internet and may be used to determine the compatibility of pressure switch wetted parts with the chemicals encountered in the measured medium.

A pressure switch with a brass pressure sensing port and elastomeric diaphragm (such as Buna N or Viton) may work well for some applications but will not last as long as a pressure switch with the chemical resistance of a weld-sealed stainless steel diaphragm and sensing port in many industrial applications.

Cycle Life and Cycle Rate

The number of times the pressure switch will be activated will have a direct impact on its longevity. Inherent in their design, electromechanical pressure switches have moving parts that are subject to fatigue affected by factors like magnitude of pressure changes and temperature. Diaphragm switches will typically provide >500k cycles. A piston design pressure switch can typically provide >1 million cycles and is more reliable than a diaphragm design when subjected to frequent large pressure excursions, pressure surges and spikes. With no moving parts, solid state pressure switch wear is reduced, typically allowing >50 million cycles.

The rate at which a pressure switch is cycled will also impact its longevity. An electromechanical pressure switch with a diaphragm works well for applications with a cycle rate of 25 per minute or less. Piston design mechanical switches are usually suitable for up to 50 cycles per minute. With no moving parts to wear out, a solid state switch should be selected for applications requiring rates that exceed 50 cycles per minute.

Electrical Characteristics

Electromechanical pressure switches harness the pressure of the medium being sensed to mechanically operate a snap-acting switch – no external power supply is required for the pressure switch to operate. Typically, electromechanical pressure switches are provided with SPDT or DPDT contacts rated for 3 to 15 amps and voltages from 120VAC to 480VAC. With solid state switches, an external power supply, usually 24VDC, is necessary to power the electronic circuitry inside the switch. The outputs of solid state switches are typically normally-open and normally-closed transistor switching outputs rated for about 500mA and 30VDC.

ProSense Pressure Switches

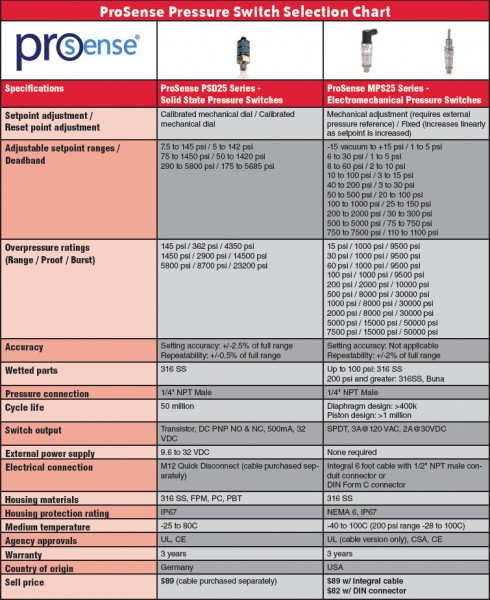

AutomationDirect offers our ProSense line of pressure switches which includes both solid state and electromechanical pressure switch designs. Our switches offer the specifications to meet many industrial and commercial applications and are all available for same day shipping. Use the following selection chart to help select the best ProSense pressure switch for your next application.

Read more articles about process sensing & control here!

Click Here to Shop: www.AutomationDirect.com/Pressure-Switches

Originally Posted: Sept. 24, 2013