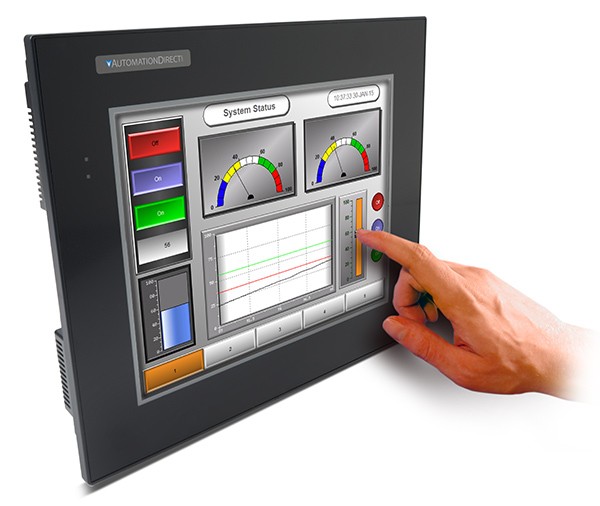

Many control systems these days need a way to interact with the process or machine operator. Legacy systems might present a whole panel full of pushbuttons, lights and switches; the development of electronic HMI (Human Machine Interface) devices made operator control and monitoring operations much more flexible, presenting text, graphics and even video to help the operator make quicker and more informed decisions.

“Embedded” HMIs are black boxes with a text or graphical screen that execute a configured set of displays and actions, typically running on a proprietary hardware/firmware platform. Connected to a controller via a communications port, these devices, such as AutomationDirect’s C-more, have come a long way in the last 20 years. It used to be that HMIs were just a convenient way to control a local PLC because you didn’t have to wire up all those buttons and switches and you didn’t have keep to re-wiring everything as the system grew. You could just download a new HMI configuration, which saved you time and money.

SCADA (Supervisory Control And Data Acquisition) systems used to be primarily for control and monitoring of much larger, complex or widely distributed systems, such as in the oil and gas industry and utilities. They can both give you a convenient graphical user interface that makes it easy to view and control your operations. And now that many embedded HMIs have remote access, mobile apps, data logging, HDMI outputs, USB ports, audio, etc, they are taking over functions that were traditionally SCADA system space.

So how do you know when you need a dedicated HMI vs. SCADA system?

If you just need to control a machine or a system from a dedicated touch screen panel, then you really can’t beat embedded HMIs because they are robust, they come in different sizes, are an inexpensive self-contained solution, and are easy to configure (and reconfigure) – you just drag and drop buttons, lights and other objects such as trend graphs on the screen, associate those items with tags and you are good to go. Hardware and configuration software are typically lower-cost, making an embedded HMI cost-effective for even the smallest of control systems.

If you just need to control a machine or a system from a dedicated touch screen panel, then you really can’t beat embedded HMIs because they are robust, they come in different sizes, are an inexpensive self-contained solution, and are easy to configure (and reconfigure) – you just drag and drop buttons, lights and other objects such as trend graphs on the screen, associate those items with tags and you are good to go. Hardware and configuration software are typically lower-cost, making an embedded HMI cost-effective for even the smallest of control systems.

SCADA systems can be that simple, but they can also allow you to do a lot more. They typically require a PC platform, and the development and run-time software packages can be more expensive and have a steeper learning curve.

SCADA systems would be more appropriate if you need more data gathering and analysis, or a better way to distribute operations data to many targets. Consider a software-based HMI/SCADA system when you need:

- an open architecture PC-based solution and the flexibility of adding your own Visual Basic Scripts or .NET extensions

- to interface with your company’s databases, ERP systems, or OPC servers

- more processing power to view 2D and 3D animations or videos

- to interface with a wider range of systems or messaging protocols

- the redundancy or security of fully automatic backups

Of course, these functions are all more programming-intensive so they can require quite a bit more effort in system design and development.

Once you have decided which direction you want to go, AutomationDirect has everything you need to get up and running. From the inexpensive C-more Micro HMI, to the full-featured C-more HMIs all the way up to the software-based Point of View SCADA system.

To learn more and see tutorials on embedded HMI configuration, visit these resources:

[list style=”orb” color=”blue”]

[/list]

To learn more about the Point of View software, check out the HMI/SCADA chapter in our Automation VIDEO Cookbook.

“Tech Tip” videos guide you through the selection of Point of View software components for purchase, as well as demonstrating some of the basic functions in the software.

The “How To” videos show how to configure and connect Point of View to CLICK, Do-more or Productivity series PLCs.

[hozbreak]