CO2 powered drag strip teaches students the science of speed.

John Harpell’s 9th grade class at Moira Secondary School in Belleville, Ontario, Canada has built and automated a model racecar track for CO2 powered “dragsters” using various components from AutomationDirect. A CO2 powered dragster is a small lightweight vehicle fitted with a CO2 cartridge; think “pine-wood-derby on steroids”. The CO2 cartridge is punctured on the starting line, and the vehicle is propelled (rapidly!) down the track by the release of the compressed carbon dioxide gas. Individual students craft these model cars in various shapes and then compete in side-by-side drag races on the flat, level track that the class has constructed. Speeds can reach 65 MPH, with elapsed times around one second or less.

The Track

Before the students could race any dragsters, they had to build the track. The class brainstormed a number of ideas after completing some basic research and studying what was realistic and affordable. They reported that the AutomationDirect Web site was very useful when researching electronic components such as photoelectric eyes (NPN vs. PNP), momentary contacts, 24V relays, and digital timers.

They constructed the two lane track from 6mm plastic sheet and 1.25″ x 1.25″ aluminum channel. The students had the opportunity to lay out, measure and drill mounting holes, and then to bolt the entire track together in 8-foot sections for a total of 48 feet of track.

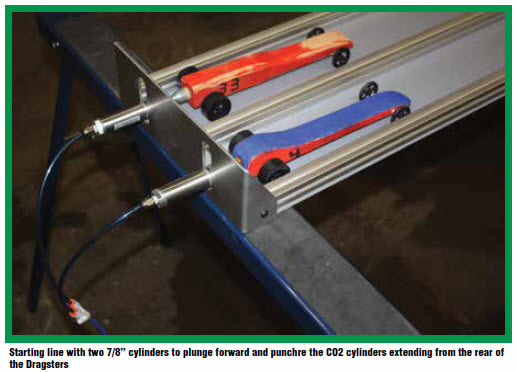

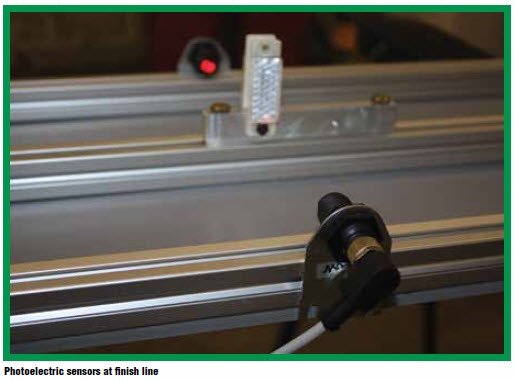

The control and timing system consists of a Start button which actuates a pneumatic valve causing two 7/8″ cylinders to plunge forward, puncturing the CO2 cylinders extending from the rear of the cars. The Start button also triggers two KOYO Digital Timers (KT-V4S-C-D); one for each lane, which increment in thousandths of a second until a car breaks the beam of the photoelectric eye at the end of its respective lane. When the beam is broken, it opens the contact on a 24V relay which, in turn, signals the timer to stop counting, leaving each car’s “Elapsed Time” displayed on the timer for that lane. The use of a photo eye with 1kHz switching frequency coupled with the precision Koyo timer yields an accuracy of 1/1000 of a second for each lane.

The control and timing system consists of a Start button which actuates a pneumatic valve causing two 7/8″ cylinders to plunge forward, puncturing the CO2 cylinders extending from the rear of the cars. The Start button also triggers two KOYO Digital Timers (KT-V4S-C-D); one for each lane, which increment in thousandths of a second until a car breaks the beam of the photoelectric eye at the end of its respective lane. When the beam is broken, it opens the contact on a 24V relay which, in turn, signals the timer to stop counting, leaving each car’s “Elapsed Time” displayed on the timer for that lane. The use of a photo eye with 1kHz switching frequency coupled with the precision Koyo timer yields an accuracy of 1/1000 of a second for each lane.

The Cars

John stresses the importance of the design process to his students before they begin to build the actual CO2 dragsters: “The design process helps the students understand the relationship between friction, drag and weight. The students conduct their own research and analyze the information to select the best design for their own vehicle. Each student is required to create sketches and drawings showing the development of their dragster’s final form. The design of this vehicle is not a linear process, it is expected that many revisions to the design will occur. Thus, each student’s dragster will have a different form that is based on their design.”

The CO2 powered cars must be built to certain specifications for the success of a particular design and to ensure safety on the track. The designs must avoid any interference with the propulsion system. Wheel placement, launch system specifications, and guidance system details are all critical to prevent failure or damage during testing. During the construction phase the students learn to use many hand tools, as well as shop machinery and safety equipment, and to identify and prevent any associated safety hazards.

The students quickly realize that certain construction techniques are critical to their car’s success. Axle holes are drilled on a drill press to ensure perpendicularity. The students sand and paint their car bodies with high-gloss paint to reduce surface drag. Axles and wheels are fitted carefully. And finally they are ready to test their designs!

Race Day

Students are expected to set up and organize “race day” with very little assistance from the teacher. The cars are weighed in and assigned to categories according to weight. Race results are recorded by students who officiate the heats. The competition format is “single elimination”, with the winner of each heat moving on to race again. The winning cars from each category compete in a final bracket to determine the overall winner.

Students are expected to set up and organize “race day” with very little assistance from the teacher. The cars are weighed in and assigned to categories according to weight. Race results are recorded by students who officiate the heats. The competition format is “single elimination”, with the winner of each heat moving on to race again. The winning cars from each category compete in a final bracket to determine the overall winner.

More information about CO2 racing (including various kits of parts available for sale) can be found here: http://www.science-of-speed.com

Although the Moira School runs their event independently, the Technology Student Association (TSA) organizes a series of CO2 racing events each year.

by. Chip McDaniel

Originally Posted: March 19, 2014