Let’s say you have a system with some Variable Frequency Drives (VFDs) and you want to integrate those VFDs into your emergency stop circuit to ensure the VFDs will place the motors into a safe state upon an emergency stop condition. How do you do this? There were many ways this was done before advanced…

AutomationDirect has recently introduced the NEW GS20 sensorless vector, general-purpose VFD. The GS20 was introduced to not only replace the GS2 series VFD but to also fill the gap between the lower cost GS1 VFD and the GS3 that is on the higher end of features for a general-purpose VFD. As the features of the…

Modern variable frequency drives incorporate several control modes to help users fine-tune operation for various applications. Kevin Kakascik, Technical Marketing Engineer at AutomationDirect, wrote an article for the June 2020 issue of Processing titled Choosing VFD Control Modes. Here’s a summary, click on the link above for the full text. Variable frequency drives (VFDs) always…

Improved performance, ease of use, and energy savings combined with IIoT capabilities make VFDs the right choice for many process industry motor applications. Bryan Sisler, Product Manager for Drives and Motors at AutomationDirect, wrote an article for the May 2020 issue of Processing titled Beyond Process Control with VFDs. Here’s a summary, click on the…

Many VFDs now have on-board logic programming and I/O, enabling them to perform real-time control for localized applications. Jeff Payne, Product Manager for the Drives & Motors Group at AutomationDirect, wrote an article for the April 2020 issue of Design News titled The Logic of Balancing VFDs and PLCs. Here’s a summary, click on the…

Application StoriesDrivesHMIIssue 44 - 2020Notebook IssueOperator InterfaceProductVariable Speed Drives

Automating the Hendrick’s Gin Grand Garnisher

The Grand Garnisher has been turning heads as it tours the United States and Europe. AutomationDirect hardware and software automation underpins the attractive, steampunk contraption. By Stuart Ostroff, Salmon Studios Picture this: you are in the back garden of the grand duke’s estate, enjoying social hour with great company, a botanical cocktail in your hand….

ApplicationApplication StoriesDrivesHMIIndustryIssue 42 - 2019Machine ControlManufacturingMotorsNotebook IssueOperator InterfacePLCProcess ControlProductProgrammable ControlVariable Speed Drives

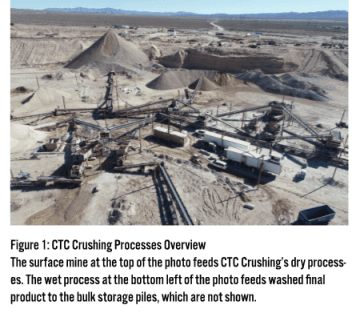

Crushing the Control System

Upgrading to a modern control system platform with the help of a local system integrator transforms a rock crushing plant from manual to fully automatic operation. By Todd Timpa, Assistant General Manager at CTC Crushing Impact Sand and Gravel is the leading supplier of aggregate and sand in the Las Vegas area, producing and distributing…

Learning ResourcesMachine ControlMotor ControlsOnline BlogProductProgrammable ControlVariable Speed Drives

Programming and Setup Considerations for VFDs with Integrated PLCs

Control capability built-in to VFDs are moving machine intelligence to the edge. Jeff Payne, Product Manager for AutomationDirect, wrote an article for the March 2019 issue of Design World, titled VFDs with integrated PLCs for motion and machine controls: Programming and setup considerations. Payne explains how AC drives can be controlled by either an external…

When powering AC motors, the electrical supply can be at full power to run at full speed, or at variable power to run at variable speed. Applications with fluctuating loads benefit from the variable speed provided by an AC drive because less power is used at lower loads and speeds, and this article explains how…

Have you seen the latest Automation Video Cookbook Chapter? There are over 40 videos showing you step by step how to use all the amazing features of the GS4 Variable Frequency Drive and more being added all the time! Want a quick start with the bare minimum info you need to get up and running…