Have you noticed a gap in the industrial controllers market? PLCs are good at handling your low end applications, but on the high end, many suppliers want to push you into distributed control systems or other expensive and complicated solutions. What’s needed is a controller in the middle, one not too big and not too small, but just right.

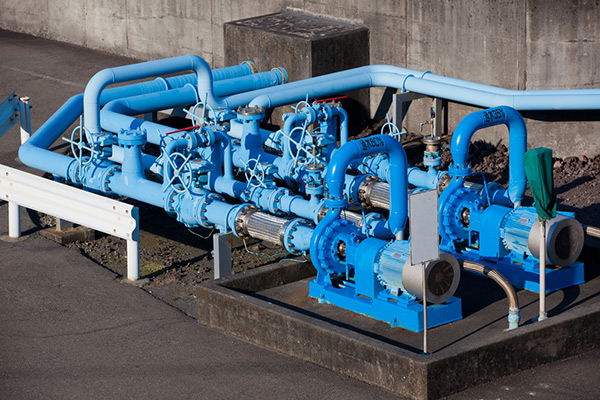

The need for a “just-right” controller often arises for control of complex pumping and other related processes. This is due to the complicated nature of pump flow and pressure control, and the need to interface to smart instruments, valves and analyzers. Most PLCs aren’t up to the task, and a distributed control system (DCS) is just too expensive and unwieldy.

To fill this gap, PLC-based PACs are now available. Unlike a PLC, a PLC-based PAC can:

- Execute advanced process control algorithms

- Handle complex functions and calculations

- Easily integrate with smart instruments, analyzers and valves

- Store large amounts of data

- Allow advanced data handling

- Easily integrate with higher level computing systems

- Handle thousands of analog I/O

Why Do Pump Systems Need APC?

Complex pumping systems often require advanced process control (APC) for loops where simple PID isn’t sufficient because of long dead times, non-linearity or other process anomalies. Leading APC strategies include model-based, inferential and sequential control.

Just about every DCS is good at APC, but this capability is seldom found in PLCs. On the other hand, most PLC-based PACs have some APC capability built in and allow for complex custom coding to control difficult loops.

So, the PLC-based PAC can handle many of your APC needs with simpler implementation than a DCS, and it’s a better solution than trying to push a basic PLC outside of its comfort zone.

Smart Instruments Only Talk to Smart Controllers

Custody transfer and other complex pumping systems usually have lots of instruments and analyzers, many of them multi-variable to measure multiple parameters. Most of these devices will be “smart” with a built-in two-way digital data link, as opposed to simple “dumb” devices with just a 4-20mA output proportional to the measured variable.

A smart device sends measured variable information to the controller, and also information related to diagnostics and calibration, which all together can run into hundreds of parameters.

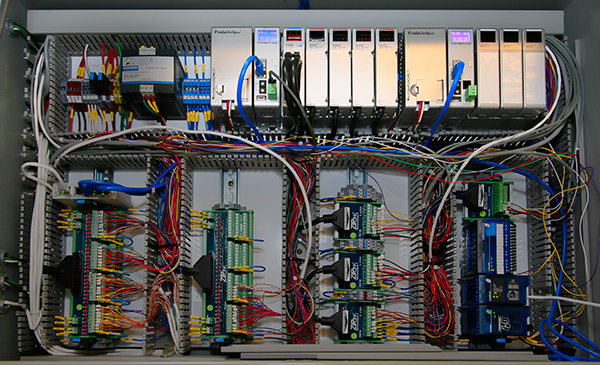

A DCS can handle smart device communications such as EtherNet/IP, Foundation Fieldbus and Profibus. But a PLC usually can’t, once again creating a need to use a PLC-based PAC with its extensive array of communication ports and protocols.

These ports and protocols not only enable communication down to smart devices, but also up to higher level computing systems, such as an enterprise resource planning or a computerized maintenance management system.

These higher level interfaces often require interface with SQL, Access or other ODBC database applications—a task easily handling by a PLC-based PAC as it allows manipulation of external databases via standard actions such as insert, delete, update or select.

Lots of Data Needs Lots of Controller

Smart devices produce lots of data, easily handled by a DCS but not by a PLC. Most PLC-based PACs come with integrated mass storage devices such as removable USB drives and microSD cards to store lots of data locally. Custom utilities allow for data to be compressed using techniques such as only storing data when it changes by a significant amount.

PLC-based PACs usually provide the option to remove the memory device from the controller so files can be downloaded to a PC or laptop. Many also have built-in web server functionality, allowing access to data via any standard web browser once proper security procedures have been followed.

Thousands of I/O? No problem.

Applications with thousands of I/O are common for a DCS, but can choke a PLC, particularly if much of the I/O is analog.

A typical PLC-based PAC will have memory space comparable to a DCS, allowing it to support applications with thousands of I/O points, and corresponding high demands for program space.

Unlike many PLCs, a PLC-based PAC will usually have a tag-based control environment, providing the flexibility to assign data types and memory allocation as needed. By contrast, most PLCs have a fixed-memory map, providing no flexibility with respect to memory allocation.

It’s a Wrap

Control and monitoring of complex processes, many of which contain large numbers of pumps, has been the province of the DCS. While a PLC costs less and is simpler to use, it often lacks the required capabilities. The PLC-based PAC occupies the middle ground, providing advanced functionality at a reasonable cost and with relatively simple implementation.

To read more on this topic, please view the article titled PLC-Based PACs Control Complex Pumping Processes in the February 2016 issue of Pumps & Systems, authored by Jeff Payne, Automation Controls Product Manager at AutomationDirect.

To learn more about programmable control, click here

Originally Published: February 2016