Industrial automation designers now have a variety of ways to incorporate an open programming approach for their projects. Although industrial-grade digital technologies have been available for over five decades, much of that time the hardware and software has been specialized and even proprietary. This is at odds with a large segment of the commercial market,…

Motion-optimized PLC platforms combine traditional controls functionality with advanced multi-axis motion control, providing a streamlined automation solution. Industrial motion control applications range from simple to complex and are generally considered a design specialty. Currently, there are some entry-level solutions, and designers are also aware of high-performance motion control platforms. However, there are many cases where…

Edge-enabled PLCs are an accessible and affordable way for most users to collect and create value from use field-sourced data. While many operations personnel at production and manufacturing companies are aware that their automated equipment can be a source of valuable data for analytics and other purposes, far fewer companies are positioned to create the…

Improved technologies and expanded user demands have pushed the evolution of industrial automation technologies, and PLCs continue to advance and meet these needs. Almost a decade ago, Jeff Payne at AutomationDirect wrote a Control Engineering article titled Future of the PLC . At that time, PLC technology was already 50 years mature but still a…

This electrical contractor relied on AutomationDirect PLC and HMI hardware and software to rapidly rip-and-replace the controls on a failing rock crusher. Equipment used in rock quarrying operations is subjected to extremes of dirt, vibration, heat, and more, pressing mechanical and electrical systems to the limit. When the crushing equipment legacy automation at one site…

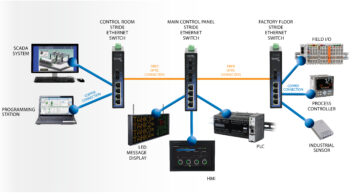

Once only suitable for sheltered office installations, Ethernet media and protocols can now efficiently serve and future-proof a variety of industrial applications. Once upon a time (think 1980s), Ethernet was a relatively specialized computer connectivity technology, administrated by experienced gurus under highly-controlled office settings. Since then, technology and performance have advanced incredibly, and much of…

Solar thermal installations need advanced control systems to optimize energy harvesting, storage, and distribution at remote mining operations. For certain applications in the right geographic areas, solar thermal can be a cost effective and low carbon way to supply large-scale heat energy. Flemming Jørgensen, of Jorgensen Thermal solutions, supplies these systems, and he needed to…

The Do-more BRX PLCs are very powerful controllers that utilize device-centric programming, allowing common functions to be configured as “devices” that run in the background without any ladder code and independent of the PLC scan. One such function is Modbus communication which, with the release of Do-more Designer 2.9.1, can be done via the new…

There are many practical and cost-effective ways for designers to incorporate automation redundancy for systems of any size. Automation redundancy has largely been reserved for larger process automation systems due to cost and complexity. However, there are now more products and design strategies suitable for applying redundancy to smaller-scale systems. Rin Irvin at AutomationDirect covers…

To improve performance and reliability, this grain blending company knew it needed to upgrade its homebrew controls to a modern control system platform. Many small- and mid-sized manufacturing operations have some degree of automated equipment, but lack the in-house skill to perform upgrades and capital projects. Ethan Taylor founded Taylor Controls to help this market…