This electrical contractor relied on AutomationDirect PLC and HMI hardware and software to rapidly rip-and-replace the controls on a failing rock crusher. Equipment used in rock quarrying operations is subjected to extremes of dirt, vibration, heat, and more, pressing mechanical and electrical systems to the limit. When the crushing equipment legacy automation at one site…

Solar thermal installations need advanced control systems to optimize energy harvesting, storage, and distribution at remote mining operations. For certain applications in the right geographic areas, solar thermal can be a cost effective and low carbon way to supply large-scale heat energy. Flemming Jørgensen, of Jorgensen Thermal solutions, supplies these systems, and he needed to…

There are many practical and cost-effective ways for designers to incorporate automation redundancy for systems of any size. Automation redundancy has largely been reserved for larger process automation systems due to cost and complexity. However, there are now more products and design strategies suitable for applying redundancy to smaller-scale systems. Rin Irvin at AutomationDirect covers…

To improve performance and reliability, this grain blending company knew it needed to upgrade its homebrew controls to a modern control system platform. Many small- and mid-sized manufacturing operations have some degree of automated equipment, but lack the in-house skill to perform upgrades and capital projects. Ethan Taylor founded Taylor Controls to help this market…

By partnering with a local systems integrator and using AutomationDirect products, this machine shop enhanced its capabilities, allowing it to deliver the services required by its customers. Throughout the country, networks of small businesses—including machine shops and systems integrators (SIs)—innovate and integrate to deliver successful projects. One example is a collaboration between Stephens Machine and…

Intelligent HMI advances can justify upgrades based on significant improvements associated with ease-of-use, cybersecurity, and other advanced features. Consumers are accustomed to rapidly upgrading their personal electronic devices by buying new hardware and updating apps, but the industrial automation world usually works at a slower and more delayed pace in this regard. Greg Philbrook, HMI…

A truck customization shop expanded their capabilities by offering AutomationDirect PLCs and HMIs to control expansive on-vehicle lighting displays. Just as many car owners like to customize their rides, there is a growing convoy of truck operators who like to do the same as a personal and promotional statement. Dickerson Custom Trucks has been catering…

Human beings are visual creatures. It’s believed that our brains can process visual information 60,000 times faster than text, with 90 percent of information transmitted to the brain being visual and over half of the brain being devoted directly or indirectly to vision. Knowing that, it’s easy to see how a visualrepresentation of an automated…

ApplicationApplication StoriesFood and BeverageHMIIndustryIssue 51 2024Machine ControlOperator InterfacePLCProductProgrammable Control

In-House Automation Focuses on People, Plant, and Profit

A cheese manufacturer developed in-house automation capabilities to keep legacy equipment running and responsively adjust to production demands. Many companies rely on external firms for automation upgrades and changes, and this works well for countless applications. But Pacific Cheese Company faced a dual challenge of maintaining and improving manual and legacy systems, while at the…

CommunicationsData and IIoTData System MonitoringIssue 51 2024Operator InterfaceProgrammable Control

Modern PLCs Provide Support for Advanced Data Access

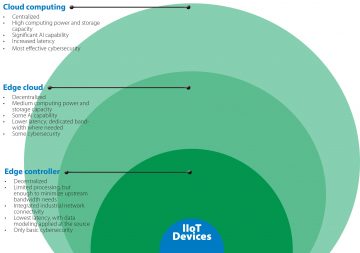

Although many think of PLCs as primarily for real-time control, modern versions make it easy to implement extensive data connectivity and analytics. While everyday consumers are familiar with getting things their way, this type of flexibility has often been less available within the industrial manufacturing arena. This is an issue for many end users when…