Because of certain drawbacks of physical contact style sensors and switches such as limit switches and float switches, newer technology non-contact style sensors have become prevalent in industry, performing well in many applications.

Proximity, photoelectric and ultrasonic sensors can be used in many applications for which they were previously never considered. These non-contact sensors are available with a variety of output configurations, such as normally open and normally closed contacts, as well as analog output configurations. An application possibility would be using an inductive proximity sensor with an analog output to replace a traditional limit switch used for monitoring a cable pulley system. The analog output would detect when the cable is starting to stretch and send a signal to maintenance personnel so actions could be taken to prevent unnecessary or unscheduled shutdowns. Conversely, a limit switch may only detect when the cable is out of specification or the switch might fail due to the wear and tear of physical contact with the cable.

The more recent style of non-contact sensors shows that “Thin is In”. Market trends show that shape and size are important. Users are looking for smaller and more accurate sensors. New technologies for the sensing circuitry as well as moldings for the housings are breaking application barriers. Sensors are fitting into much tighter areas than ever imagined.

Advanced Features

New sensor “features” is another trend that is gaining momentum. Proximity sensors are incorporating status LEDs that are visible 360 degrees around the sensor. The LEDs provide more information than just sensing indication. For example, a status LED can pulse to indicate a weak detection signal, possibly caused by a sensor coming out of adjustment or by a foreign object such as grease covering the sensor surface. Advances such as this will be an

invaluable feature for end users to help diagnose problems. Well-trained maintenance personnel can detect the pulsing LED and take action before a process is shut down unnecessarily.

Smaller size equals lower cost

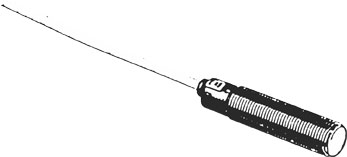

Sensors are starting to take shape from the inside, thus changing their outside dimensions and mounting options. Sensor manufacturers are incorporating technologies such as application-specific integrated circuits (ASICs) to drive down size and cost and to increase ease of use. By using ASIC technology, a large number of components can be integrated onto a single chip, allowing sensors to achieve sensing distances of up to three times that of more common sensors, in a package smaller than 8mm in diameter.

ASIC technology is also providing a more precise sensor. Sensor manufacturers do not have to rely on special machines to “calibrate” a trimming resistor in order for each sensor to be within specification. The ASIC technology allows the sensors to be calibrated digitally via programming devices.

A sensor that incorporates ASIC technology can be manufactured at a reduced cost by lowering the number of components needed to control the sensor and reducing the labor required to assemble the units, which equates to less cost for the end user. Since the sensors can be assembled more quickly, sensor manufacturers can benefit from lower inventory overhead.

Common production methods such as gaskets, glue and epoxies are no longer the best choices. Designs are now relying on such techniques as overmolding and ultrasonic welding. This type of fabrication provides the tight seals and rugged packaging needed in industrial environments.

With more functionality in a smaller package, consumers typically using 30 mm sensors can now use 18 mm sensors, and 18 mm sensors can be replaced with 12 mm units. The 12 mm sensors have become one of the most popular sizes, and the 8 mm inductive proximity sensors, having up to 3 mm shielded and 4 mm unshielded sensing distances, are starting to take an increased market share.

Photoelectric fits right in

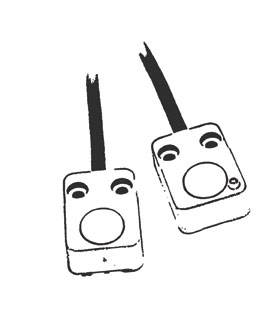

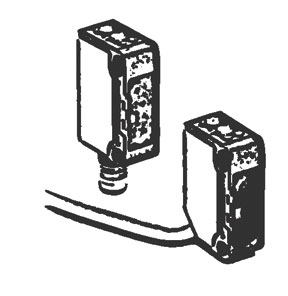

Photoelectric sensors are also becoming much smaller in size. The trend for these sensors is moving from the big rectangular style package to a much more compact style in both miniature rectangular and cylindrical configurations. Benefits to machine builders include the ability to locate the sensors closer to their targets to utilize the full strength of the optics. Where certain applications demanded installation of a sensing head connected to cables and a separate processing unit, the smaller photoelectric sensors can be mounted in tighter and more obscure places. In addition, the compact size still maintains the high reliability and durability needed for the industrial market.

Photoelectric sensors are also becoming much smaller in size. The trend for these sensors is moving from the big rectangular style package to a much more compact style in both miniature rectangular and cylindrical configurations. Benefits to machine builders include the ability to locate the sensors closer to their targets to utilize the full strength of the optics. Where certain applications demanded installation of a sensing head connected to cables and a separate processing unit, the smaller photoelectric sensors can be mounted in tighter and more obscure places. In addition, the compact size still maintains the high reliability and durability needed for the industrial market.

Lasers increase precision

The use of lasers in sensors is providing great improvements in precise position detection, counting, and inspection applications. These types of sensors are able to detect position changes in distance and thickness of less than a business card. This helps users dramatically reduce process errors and prevent defective products from entering the marketplace. Laser technology is also lowering manufacturing costs and sale prices, providing inexpensive solutions to sensing needs that could not be met in the past.

Ultrasonics improve detection

Ultrasonic sensors are also becoming smaller and more cost effective. Ultrasonic sensors have a great advantage over typical proximity and photoelectric sensors because they have very good sensing ranges while not being affected by environmental factors such as dust. Ultrasonic sensors are being designed so there is almost no dead zone in the detection area. Since these sensors operate with sound wave technology, they can detect many materials not practical in the past. Another advantage of an ultrasonic sensor is that one sensor can be used for many materials without any extra setup or sensing concerns. For example, an ultrasonic sensor that detects a clear plastic film can also detect a red plastic film. This type of dynamic operational change could be difficult if a standard clear object style photoelectric sensor were used.

For the future, the trend will be to continue to provide smaller, more affordable sensors that have the flexbility to fit even more applications in both industrial and commercial environments.

Click here to learn more about sensors.

by Lenny Filipkowski,

Product Engineer for Power Distribution and Industrial Control Products, AutomationDirect

Originally Published: June 1, 2006