Opening the hood of your car will reveal a mass of cables and hoses running around the engine block. Somewhere in there is an alternator, which helps keep your car supplied with electric power when it’s running.

When an alternator goes bad, most mechanics will replace it with a used unit that has been remanufactured, and it might have come from our company, Motorcar Parts of America in Torrance, California. Given the number of units that have come through our shop and the expertise we’ve gained, many of our remanufactured alternators are better than the original as we have found ways to eliminate many design weaknesses over the years.

The practice of rebuilding engines and subassemblies has been going on for decades, and MPA is a major supplier of replacement starters, alternators, wheel hub assemblies, and bearings. Over the years, as engines have become more sophisticated, so has the remanufacturing and testing process.

Rebuilding an alternator from a current or recent model car is a complex process, one that demands thorough testing to ensure that performance requirements are met. Given the cost pressures always present in anything related to the automotive industry, companies that want to compete as rebuilders must be able to carry out the remanufacturing and test processes quickly and predictably. Mechanics and auto part store chains will quickly drop a supplier that causes customer dissatisfaction by supplying substandard components, so world class quality is a must.

There are thousands of alternator types in use given the variety and age of cars on the road. Even so, as part of our customer service, MPA promises 100% end-of-line testing of all remanufactured alternators. Handling a huge range of sizes, capacities, and case design form factors requires an automated testing procedure that can step through and record a series of tests faster and more positively than with manual operations, which is why we employ automated test systems.

Custom Built Test System

Since an automated alternator test system isn’t an off-the-shelf item, MPA has had to design and build much of its own test equipment. At present, MPA has rebuilding and testing recipes for more than 3,000 alternator models. This includes parts catalogs, performance parameters, test protocols and other information. To implement these test recipes in an automated fashion, MPA recently installed a new alternator test bench, built in-house with the help of automation distributor and system integrator Quantum Automation in Anaheim, California.

Any company with a complex project like this one needs to choose the right vendors to supply the required hardware and software components. To assist in the selection process, we chose Quantum Automation as our partner because they employ a sophisticated sales support staff that we knew would point us in the right direction. Quantum’s sales engineer Mike Kavanagh was particularly helpful throughout the project, starting with the design phase and assisting through startup and commissioning.

We live in a world driven by ever evolving technology and constant changes with new applications and solutions. It’s therefore a must to consult with highly trained and trusted partners before beginning any automation project. Foresaking this step could result in sourcing the wrong hardware or software.

Design Considerations

Testing a given alternator requires mounting it in the test stand, generally using the same mounts that are used with the engine. This requires drop-in retainer inserts that mate with each specific alternator case design. Electrical connections have to be made to simulate a load (Figure 1), along with data connections that communicate with the ECU (engine control unit).

The testing protocol includes spinning the alternator at specified RPM values and checking its output in volts and amps, both AC and DC. Running an alternator at full load requires the safe dissipation of high currents. A unit for a luxury SUV has to be able to power a huge number of accessories, so total output can easily be 200 A or more. The testing machine also has to talk to the unit, giving it digital instructions and receiving information using CAN bus, just as the ECU would in normal use in a vehicle.

Driven by a Stock Controller

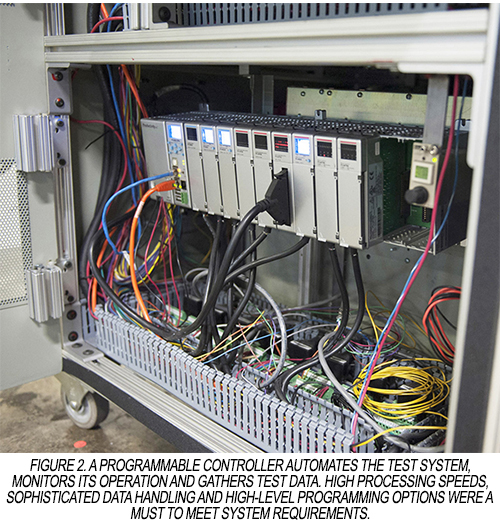

A sophisticated controller is the heart of the test system, in this case an AutomationDirect Productivity3000 Programmable Controller (Figure 2). Operators control and monitor the test system via a touchscreen PC running Web Studio Human Machine Interface (HMI) software from InduSoft; the PC is connected to the controller via Ethernet (Figure 3).

All of the testing parameters have to be programmed into the controller, with some of the more commonly used programming routines standardized as function blocks for reuse from one program to another. An in-house designed printed circuit board communicates CAN-based data to the alternator that simulates what the engine would send in normal use.

The test system also has a main drive motor that spins the rotor. Given the variety of units that must be tested, the motor has to operate over a wide speed range to match what the alternator would see in normal use. An AutomationDirect GS drive is able to control the speed as needed, although making the right connection to the Ethernet port on the controller required conversion to the RS-485 serial communication required by the GS drive.

Designed for Easy Operation

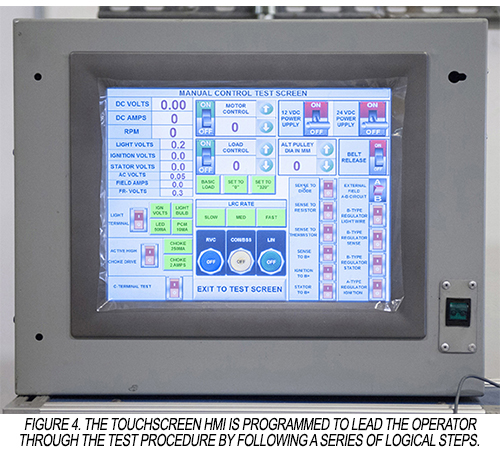

In day-to-day use, an operator has a production lot of specific alternators to test. After inserting the correct mount to affix the alternator to the test stand, the operator calls up the parameters for the specific alternator from the 3000+ alternators in the database using the touchscreen HMI. The HMI provides the appropriate test screens for the specific alternator, and the operator interacts with the HMI as required during the test procedure (Figure 4).

In day-to-day use, an operator has a production lot of specific alternators to test. After inserting the correct mount to affix the alternator to the test stand, the operator calls up the parameters for the specific alternator from the 3000+ alternators in the database using the touchscreen HMI. The HMI provides the appropriate test screens for the specific alternator, and the operator interacts with the HMI as required during the test procedure (Figure 4).

The test system first performs its own self diagnostics before beginning the actual testing process. If a specific alternator fails, the test system is sophisticated enough to diagnose which component failed or if there is another defect. It can identify this by determining which step the process was at when the failure was spotted. The quality technicians can then trace down the root cause and see if it was a component failure or some other issue. Appropriate corrective actions can then be performed according to MPA’s test procedures.

The testing program has to be fast and reliable. Once set up, testing technicians can completely test a unit in less than 90 seconds, performing about 1000 tests per day. These 1000 tests generate upwards of 250,000 total data points, and all of that information is uploaded to a larger database in the corporate server database.

Handling Large Amounts of Data

Handling Large Amounts of Data

Given that the test system has about 100 I/O points and given the amount of data that has to be gathered in a short time, the controller and the HMI have to process the data quickly and efficiently. This is complicated further since the kind of data collected when testing an alternator is different than what is typical with most industrial automation systems.

So, we had to add numerous signal conditioners, solid-state relays, and other interfaces to convert the alternator test data into formats that the controller can handle. Communications between the controller and the HMI also have to be fast, which isn’t a problem when using 100Mb Ethernet communications.

Designing, building, and programming a unit of this complexity was not an easy undertaking, but doing it using standard industrial hardware and software made for a relatively inexpensive project. In years past, the only practical approach was using proprietary hardware and software that was more costly, more difficult to program and harder to maintain. Earlier versions of a test system with this level of complexity would typically have cost two or three times what this one did, and would not have had the same capabilities. That’s the value of using off-the-shelf components to build a custom system.

Based on our experience using the Productivity3000 controller and the Web Studio software, we are looking at other parts of our manufacturing and test processes where we can increase production or improve quality through a higher level of automation. The ability to design, build, and program production and test systems like this in-house, using primarily off-the-shelf industrial automation products, has given us a lower cost threshold and allowed us to consider applications that we would have considered too costly before. [hozbreak]

Originally Posted: Feb. 2, 2015