A modern PLC automation platform will keep a classic industrial machine running for years to come. Cotton production originated thousands of years ago, but modern machines, like the cotton gin and the cotton baler (or cotton baling press), have made its processing much more efficient over the past 200 years. These machines can be kept…

ApplicationApplication StoriesFood and BeverageHMIIndustryIssue 51 2024Machine ControlOperator InterfacePLCProductProgrammable Control

In-House Automation Focuses on People, Plant, and Profit

A cheese manufacturer developed in-house automation capabilities to keep legacy equipment running and responsively adjust to production demands. Many companies rely on external firms for automation upgrades and changes, and this works well for countless applications. But Pacific Cheese Company faced a dual challenge of maintaining and improving manual and legacy systems, while at the…

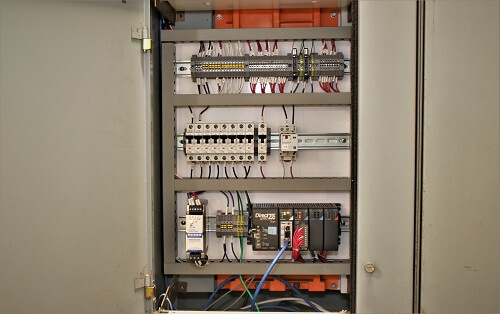

Many types of legacy equipment can last for decades from a mechanical standpoint, but periodic digital upgrades are necessary to keep these systems running efficiently. A significant amount of machinery used in manufacturing industries is built using electromechanical components that can be readily repaired or replaced to keep capital equipment in service for many decades….

ApplicationCircuit ProtectionElectrical PowerFood and BeverageProcess ControlProductRelays & TimersTerminal Blocks & Wiring

Robotic Beer Dispenser Hits the Ground Running

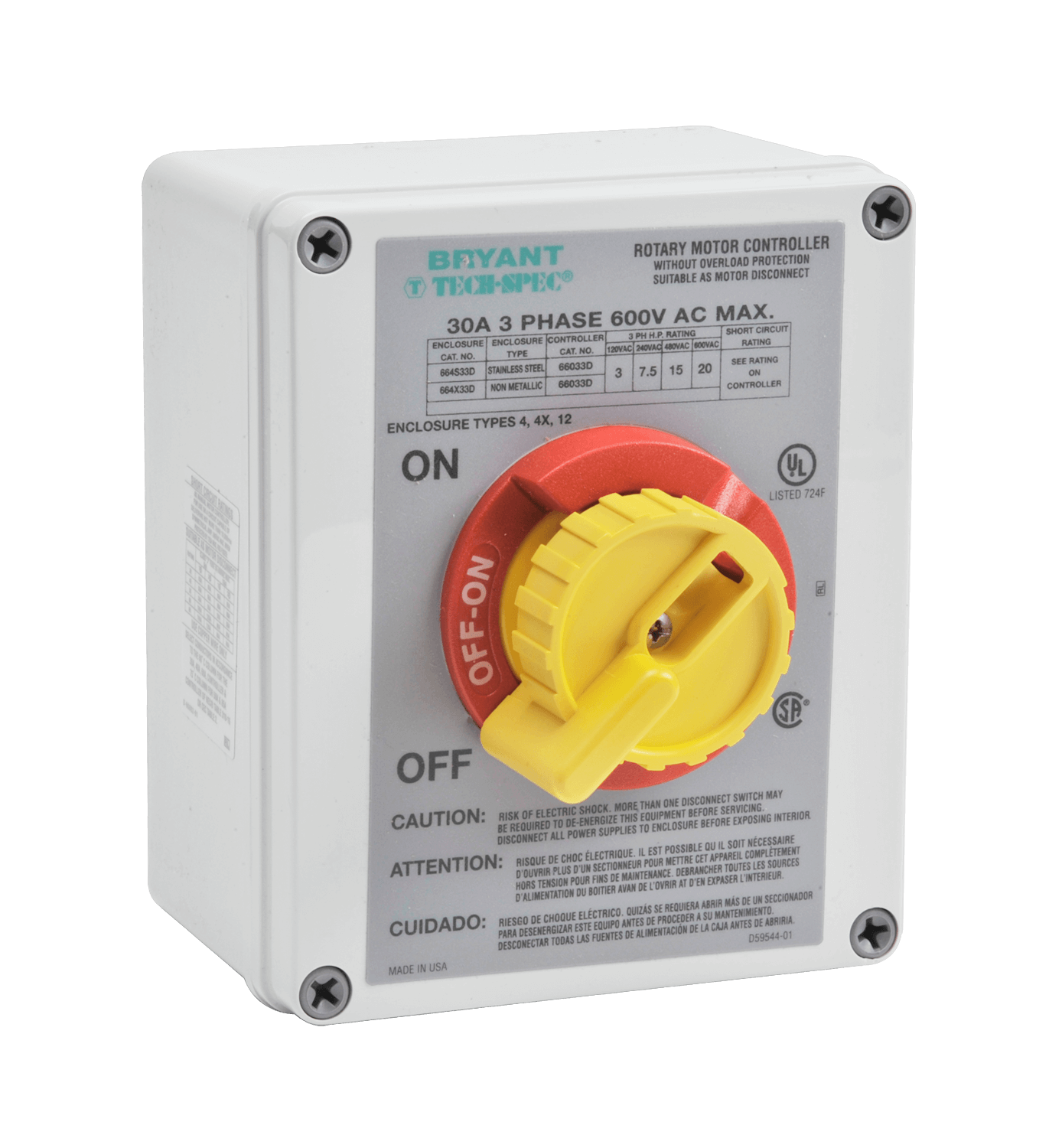

Reliable, rugged, and economical automation components are essential building blocks for bringing high-tech into consumer-facing applications. After working for more than a decade on industrial and automation projects, Grayson Dawson founded Hop Robotics to bring high-technology robotic serving systems to the food & beverage and hospitality sectors. He wrote a success story article that ran…

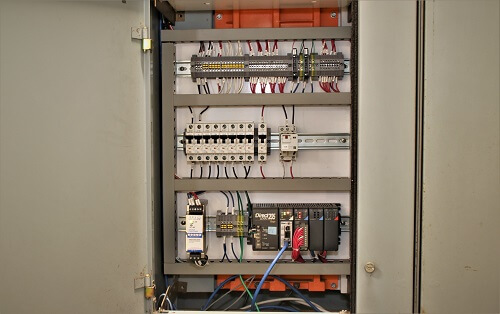

Although we generally think of industrial enclosures as protecting components inside the box, it is also important to understand how they work with the environment outside the box. Jody Kinney, product manager at AutomationDirect, wrote an article for the July 2021 issue of Processing titled Thinking Inside and Outside the Box. Here’s a summary, click…

This utility standardized and defined best practices for their applications, improving operations while saving time and money. By David Reagan, Helix Water District ndustrial automation installations come in many shapes and sizes. Applications vary from standalone machines up to large processes, and the operating organization may have just one maintenance person or field an entire…

See how a water utility standardized around AutomationDirect products to improve operations while saving time and money. A team of operations, maintenance, and engineering personnel at Helix Water District in San Diego, CA has retrofitted and constructed many sites using automation hardware and best practices based on AutomationDirect products. David Reagan wrote an article with…

One of the most common types of control components seen in the food and beverage industry are discrete sensors. Discrete applications in the food and beverage industry are processes or operations that perform a series of predetermined steps and typically use devices whose operation is either “On” or “Off”; examples include sensors that detect the…

The Food and Beverage industry is a growing and changing field that’s becoming more and more reliant on automation and finding efficiencies. Click below to download our Food and Beverage book to see all of the latest trends. Topics Include:

Automation methods used in a distillery are adapted for use in the fermentation process at a brewhouse. By: Avi Aisenberg, CEO and Proprietor at South Florida Distillers South Florida Distillers is the oldest distillery in the city of Fort Lauderdale, Florida. The company is now branching out into the design business by working with 26°…