Going Green Drives Home the Lesson at Boston Children’s Museum

Many historians reckon that the Boston Tea Party took place on the banks of the city’s Fort Point Channel. Though the site may be somewhat in question, the educational impact of another present day revolution taking place at Boston Children’s Museum is indeed very firm.

A century-old wool warehouse along the Channel is now a world of wonder for children and their parents. The recently opened 23,000-square-foot addition to Boston Children’s Museum is a must-see for the city’s residents and visitors, offering many hands-on exhibits. Exhibits include bubble-making machinery, a three-story climbing maze, the Construction Zone featuring kid-sized equipment, Kid Power that promotes healthy lifestyles, and Boats Afloat, where children can float wooden objects down a 28-foot-long model of the Fort Point Channel.

The Museum is also a must-see for architects. At last month’s (May) American Institute of Architects conference, Boston Children’s Museum was one of the highlights of a tour that included the Big Dig and the new Institute of Contemporary Art that was conducted for the members and their families.

The Museum is very much tied into the environment of the Fort Point Channel. The Museum moved to this location in 1979 with the intent of developing programs and exhibits consistent with the new waterfront home environment. A wide range of exhibits helps visitors explore waterfront habitats and learn about their creatures, while programs educate

The Museum is very much tied into the environment of the Fort Point Channel. The Museum moved to this location in 1979 with the intent of developing programs and exhibits consistent with the new waterfront home environment. A wide range of exhibits helps visitors explore waterfront habitats and learn about their creatures, while programs educate

kids and their families about the importance of enjoying – and protecting – the environment.

The Museum has made a strong effort to spread the lessons of that environment throughout the Boston public school system. During the summer the museum has brought local teachers to the waterfront location and taught them how to involve students in doing fieldwork activities. The vision of the Museum staff is to bring every Boston school child to this site to discover the ecosystem in which the Museum functions. It anticipates educating 500,000 students, teacher, parents and other visitors annually.

According to Boston Children’s Museum’s Chief Operating Officer Neil Gordon, “We have made environmental stewardship a core part of our educational vision.”

These efforts on the part of Boston Children’s Museum’s management and board have been certified by a national organization that is playing a prominent role in this country’s green building movement. The Museum project is one of a growing number of buildings registered with the US Green Building Council’s LEED® certification program and earned the LEED Gold certification. More and more projects are in the hunt to achieve the certification.

According to an article in USA Today, developers and builders aren’t joining the green revolution purely out of a sense that it’s the right thing to do. They simply can’t afford to be left behind. By the end of 2006, at least 6% of the nation’s non-residential construction, a $15-billion chunk of the industry, was expected to be green, says Greg Kats, a green-building consultant in Washington, D.C. In 2000 it was less than 1%.

The process of striving for LEED certification coordinates the efforts of the participating firms and Boston Children’s Museum’s management to reach a level of ecological harmony and minimize the building’s impact on the channel area. The roster of project participants included Cambridge Seven Architects, Inc. and R. G. Vanderweil Engineers, LLP, with the construction led by Shawmut Design and Construction, and mechanicals installed by TG Gallagher.

The LEED certification has a scoring system based on a set of required prerequisites and a variety of credits in six major categories. Credits can be earned based on factors such as site selection, water use, energy use optimization, selection of building materials, employee comfort and an evaluation of innovation in the design process. In LEED v2.2 for new construction and major renovations for commercial buildings, there are 69 possible points and buildings. To achieve the gold rating, Boston Children’s Museum scored between 39 and 51 points.

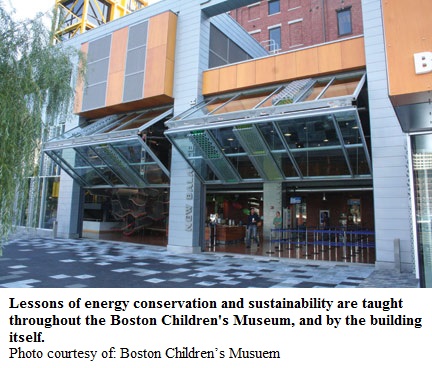

Literally the whole museum building itself is an exhibit, teaching children the lessons of sustainability from top to bottom.

Up On The Roof

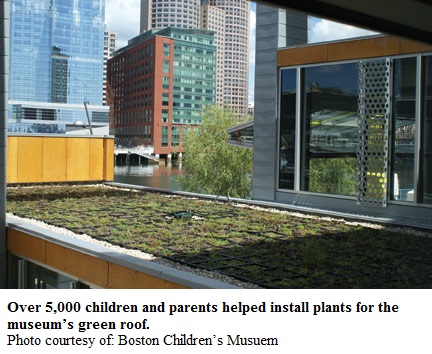

Topping off Boston Children’s Museum is an extensive green roof of plantings and organic materials. Working with the Museum’s staff, “Green Team” interns and guest scientists, more than 5,000 children and parents participated in preparing and installing the plants that form the visible green roof over the Museum’s entrance. A highly visible demonstration of Boston Children’s Museum’s green agenda, the green roof sedum and flowering plants will cover a 6,400-square-foot surface.

Over 5,000 children and parents helped install plants for the museum’s green roof.

Over 5,000 children and parents helped install plants for the museum’s green roof.

Along with irrigating the plants, the harvested water will comprise the cooling tower make-up water. Vanderweil installed a 20,000-gallon reclaimed water system in the building. As the water passes through the building, it is recycled as gray water for toilets, reducing potable water demand by 77%. Their goal is to reduce storm water discharge from Boston Children’s Museum’s site by 88%, and reduce phosphorus discharge from storm water run-off by 40%.

Gordon notes, “The water quality on the Fort Point Channel is rated among the worst in Massachusetts’s bodies of water for organic and pathogenic pollutants.”

Even with the significant private/public investments being made in improving the channel’s water quality, Boston Children’s Museum feels it is important to do its part in this effort. “Storm water if left unchecked,” notes Gordon, “will jeopardize the future of the channel.”

In The Galleries

The HVAC system at Boston Children’s Museum is set up to responsively provide the right level of heating/cooling based on visitor traffic throughout the facility. The system monitors the crowds using Kele CO2 sensors on the return air in each zone throughout the building. This information is fed to the Johnson Controls Metasys® building management system that controls and coordinates the building’s HVAC.

Recalling our high school science, humans give off CO2 as we exhale. When the sensors detect a CO2 level of 750 parts per million (ppm), the Metasys system commands the dampers on the variable air volume (VAV) make-up air boxes to open to bring fresh air into the zone.

The VAV’s help make Boston Children’s Museum’s air conditioning systems more efficient by regulating the heating/cooling load targeted toward any specific zone in the building. When a VAV box constricts a valve to let less air through, it decreases the amount of energy consumed by fans that direct the air around the building.

“The beneficial part about this system is that our HVAC in the building does not run on a set program,” according to Gordon, “[rather it] is based on real-time building usage.”

This system runs in conjunction with the 36 high efficiency heat pumps working together with a condenser water system incorporated into the existing water tower. The cooling tower’s two 40 HP fans are controlled by variable frequency drives, which control the speed of the fan motors based on a cooling load.

The 45 heat pumps positioned throughout the building to cool individual zones each have control valves for regulating the condenser loop. If some of the heat pumps do not call for heating/cooling, those valves close. The differential pressure goes up, which signals the drives to slow the pumps to save energy.

The savings on the rooftop systems are achieved through dampering down the VAV boxes when CO2 falls below 750 ppm, and adjusting the drives on the rooftop units so they are not running continually at 100% speed. Together with daylight lighting controls, the HVAC system is projected to deliver an 18% energy performance improvement.

Throughout The Building

From structural supports to flooring and railings, the Museum incorporated up to 25% recycled materials and up to 20% locally harvested or manufactured materials. In addition, materials used in the project are certified low-emitting materials to ensure the Museum maintains a high level of air quality for its visitors.

At Ground Level

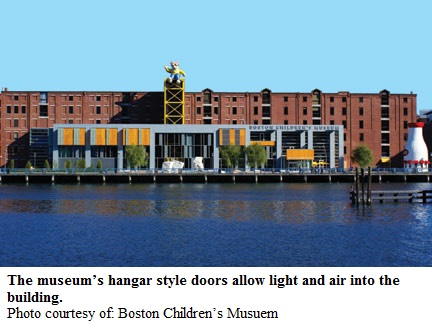

The Museum has two large 21’4” wide by 20’7” high Wilson hangar style vertical bi-folding doors that match the addition’s overall exterior design so that when closed, the doors blend into the other solid walls.

The doors are part of the Museum’s goal to connect viewers and programs to the waterfront while completely blending into the overall look of the new façade. They also support the Museum’s green mission by enhancing day-lighting and view capabilities for the new spaces.

The doors are part of the Museum’s goal to connect viewers and programs to the waterfront while completely blending into the overall look of the new façade. They also support the Museum’s green mission by enhancing day-lighting and view capabilities for the new spaces.

Lessons of energy conservation and sustainability are taught throughout the Boston Children’s Museum, and by the building itself.

As an integral part of the high window wall, the full height glazing on the doors reduces energy requirements by reducing the need for artificial lighting in the lobby. Along with using daylight for illumination, the doors are glazed with one-inch thick high-performance double-pane glass, trapping the heat of the sun to reduce winter heating and summer cooling costs.

The door is propelled by two 1HP motors rather than one 2 HP motor to provide longer shaft life for these large doors that are made heavier by the glass. The door operation is controlled by an AC drive and 3-button controller. The variable speed AC drive provides a visitor-friendly, smooth, soft start and stop at half door speed, minimizing wear on the motor and components, while significantly decreasing the opening and closing time of the door.

Investing In The Future

While Boston Children’s Museum is presented to the community as a learning experience, building the addition to the Museum was a learning experience for management as well. In the process, the Museum was able to deliver on their green mission, as evidenced by the LEED Gold certification, while fitting the project within budget constraints against the board’s adoption of a 15-year payback as the basis for analyzing cost/benefit.

But the real investment that will pay off is in the young people of Boston. As Gordon states, “the commitment to a green building is really a commitment to creating the next generation of environmental stewards.”

By Keith Schmitz,

Guest Writer

Originally Published: June 1, 2008