This automated car wash supplier needed a better way to connect with a multitude of remotely-located digital systems, and it found the solution with AutomationDirect StrideLinx.

Industrial automation isn’t just for factories, as it surrounds us and provides safe, reliable, and consistent performance for elevators, traffic lights, and even the neighborhood carwash. Aulio Gil is an electrical engineer at Sonny’s The CarWash Factory, and he wrote a success story for Machine Design January 2023 titled Cleaning Up Your Automated Processes, detailing the requirements and solution for providing IIoT and remote connectivity for carwash facilities.

A Carwash Factory

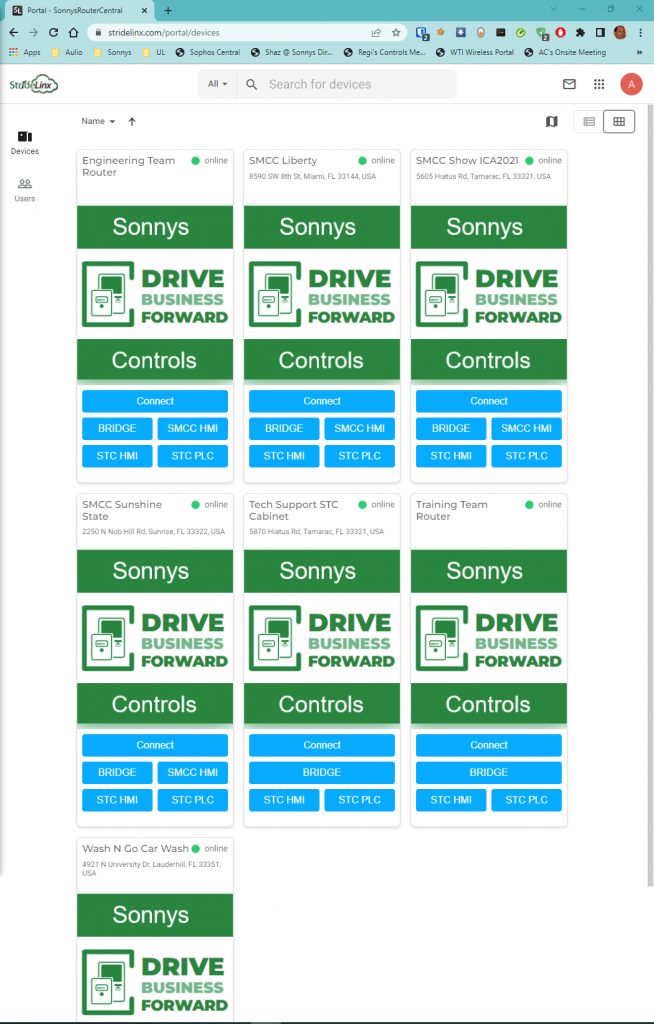

Sonny’s The CarWash Factory is the world leader in conveyorized carwash equipment, with over 700 systems in operation throughout the U.S. and abroad. These systems include significant automation and intelligent equipment, and most require off-site technical support.

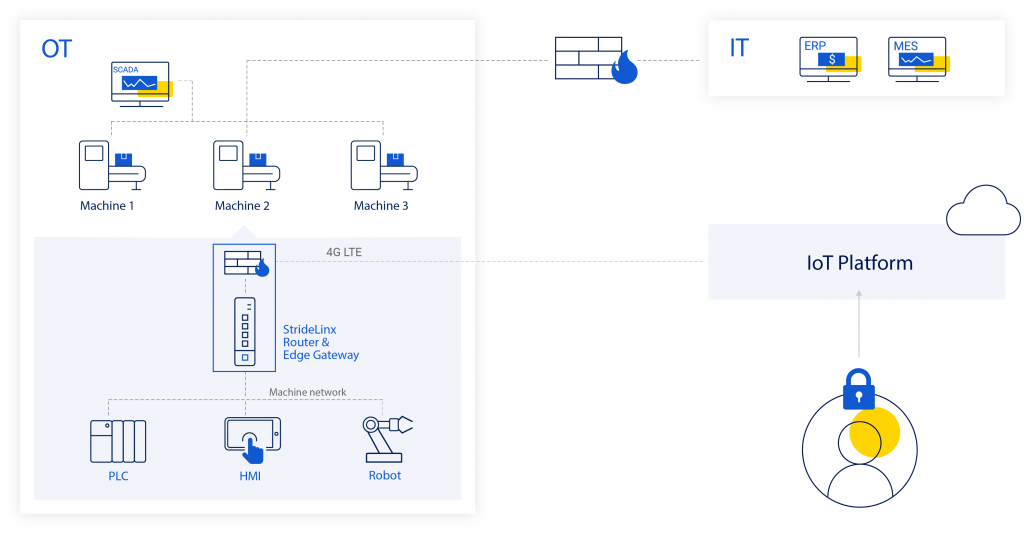

A carwash system is like a small factory in some ways, with automated PLC and HMI control of the equipment, along with significant smart motor controls and VFDs, and it adds a credit card pay station and license plate recognition. Each of these systems need to interact well with each other for best energy and resource efficiency, and operators must be notified of depleted chemicals, brushes needing replacement, or other issues.

The Sonny’s team requires secure remote connectivity to all on-site systems, ensuring that credentialed owner personnel and team members can perform tasks like:

- Real-time monitoring

- Receiving warnings and alerts via text and/or email

- Performing historical data logging for analysis

- Enabling PLC, HMI, and other program and configuration uploads and downloads

Sonny’s uses standardized programming to maintain consistency. They go a step further by handling configurations much like mobile device applications, with their systems receiving periodic updates to continually improve operations.

Getting a Clean Connection

To support these requirements, the team initially selected a solution using commercially available devices. However, this approach turned out to be complex to implement, labor intensive for support, and unreliable.

To address these and other issues, they began the search for an industrial-grade solution that could meet the challenge, and they evaluated the AutomationDirect StrideLinx VPN router and associated StrideLinx cloud service. Prior to a trial rollout, the team found the equipment to have flexible options—supporting multiple internet connection types, including gigabit wired Ethernet, Wi-Fi, or 4G LTE—along with an extensive library of documentation, online videos, and other support materials.

The router features an industrial-grade form factor, and the IIoT cloud service is ISO27001:2013 certified for security. It uses worldwide VPNs for performance and resilience, and it comes with handy mobile apps for iOS and Android devices.

Driving forward

The StrideLinx implementation has proven completely reliable, and it is essential for maximizing carwash uptime, while minimizing customer issues.

The complete IIoT solution allows quick and easy access to HMIs and PLCs, via VNC or web servers, from within the platform with a provided direct link to each device. This gives Sonny’s the ability to monitor or control machine status from the HMI on a PC or smartphone.

Based on the success of initial installations, Sonny’s is equipping new systems and retrofitting existing systems to take advantage of the performance and cost effectiveness of AutomationDirect StrideLinx for their IIoT and remote access needs.

All figures courtesy of Sonny’s The CarWash Factory