Many water utilities could benefit from using robust and standardized PLC automation, instead of enduring inconsistent and difficult to troubleshoot custom control systems.

While many people settle for things that are good enough, sometimes it takes relatively little extra effort to make things excellent. Dennis O’Hara experienced this many times as he progressed from getting an electrical engineering degree, to serving in the Marines as an officer, to working for an electric utility, and finally to creating his own automation company serving the water/wastewater industry.

Dennis’s article in Control December 2021 titled Smart Automation in the Trenches talks about his development of a PLC-based pump station control platform, focused on end-user needs for easy installation, operation, and maintenance.

Improvise, Adapt, Overcome

A Marine Corps mantra calls for soldiers to “improvise, adapt, overcome” when meeting any challenge. That is admirable for the short term, but if one has more time and resources, then a more comprehensive plan can be created.

As Dennis worked with many utility operators, he could see how difficult it was for them to support custom automation. Reliable automation is necessary for water and wastewater infrastructure systems, and Dennis began envisioning how he could provide a standardize PLC-based system to meet the need, with attributes like:

- Plenty of programming memory

- DIN-rail mounting and removeable terminals for easy service

- Communications port for SCADA data access

- LED indicators for I/O signals

- Analog signal capability for monitoring things like pump motor current

Improve, Adopt, Overachieve

With these goals in mind, Dennis turned to the AutomationDirect website and portfolio of products. Armed with these resources, he was able to create a control panel and PLC design with practical features such as:

- Electrical surge protection

- Works with all common voltages

- Control of one to four pumps

- Pressure and pump current monitoring

- Helpful alarms

- Automatic override in the even of common float failures

- Small but useful operator interface for configuration and monitoring

- Simple installation and operation: “Plug and Pump”

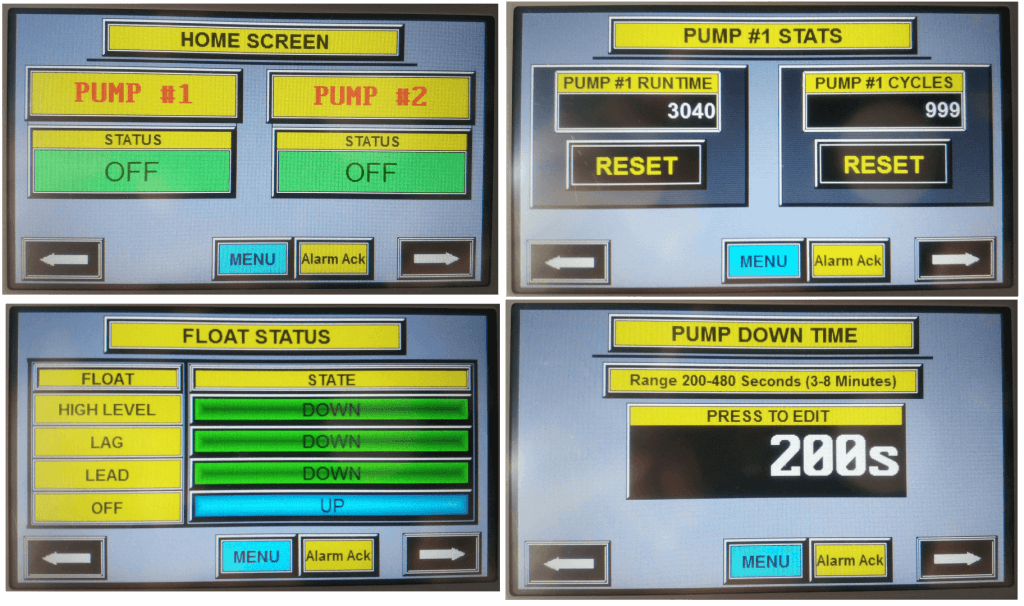

The design is based around an AutomationDirect DirectLOGIC DL05 micro-brick PLC, with a C-more Micro EA3 series touch screen HMI. The display graphics emphasize clear operational and configuration information, so it is easy for operators and maintenance personnel to use the system and perform any troubleshooting in the rare case of an issue.

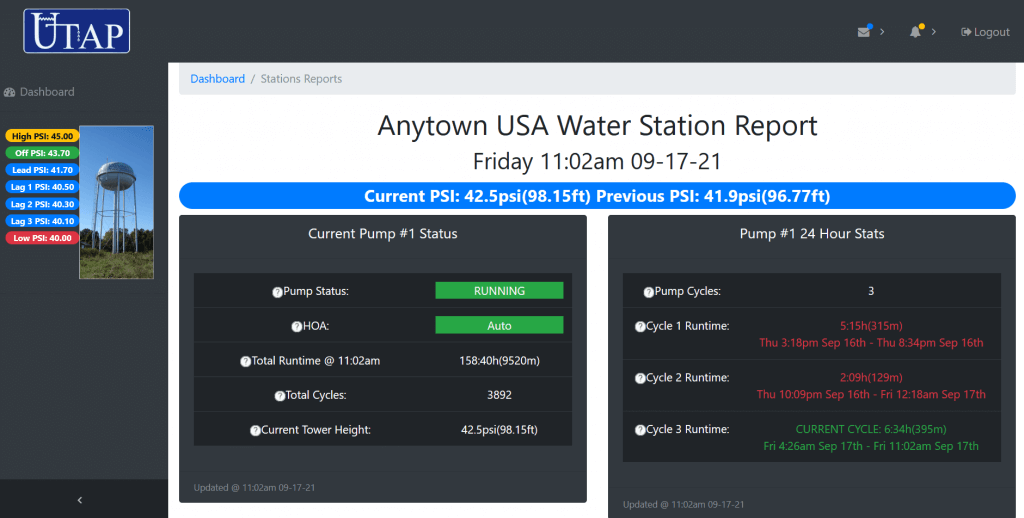

The traditional pump control systems to be upgraded used electro-mechanical relays for control, with clumsy phone dialers to annunciate alarms. The new system uses a cell modem so the controller can transmit data and provide a web-viewable display, providing cost-effective SCADA functionality.

Controlling water/wastewater pump stations is not a glamourous job, but it is crucial function.

By combining our end-user-centric design philosophy with reliable AutomationDirect devices, we believe we’ve created a flexible, helpful solution for utility operators everywhere.

U-Tap has over a dozen systems in reliable service, with new projects in progress, and can meet user needs by quickly upgrading any pump station.

All figures courtesy of Dennis O’Hara