Bulk multi-conductor cable is a convenient way to connect electrical power and signals.

Below are answers to some of the most frequently asked questions about bulk multi-conductor cable:

-

Why use a shielded cable?

-

What is the difference between cord and cable?

-

Why use VFD cable?

-

What does ‘Exposed Run’ mean?

-

What is the difference between ‘flexible’ and ‘flexing’ cable?

-

What do the letters on service cord mean?

-

What types of bulk multi-conductor cable are currently offered by Automation Direct

Why use a shielded cable?

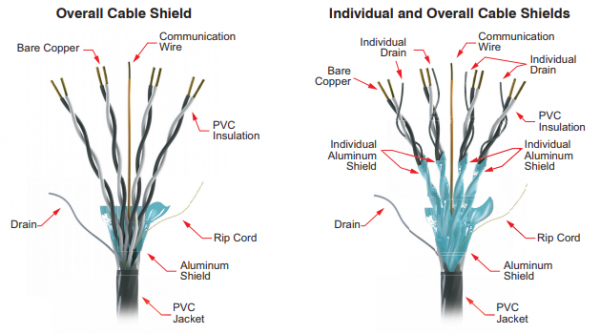

The shield in a control cable acts as a Faraday cage to reduce the effect of electrical noise on the signals, and to reduce electromagnetic radiation from the signals that may interfere with other signals or devices. And additionally, the shield minimizes capacitively coupled noise from other electrical sources.

Shields are typically made of braid or mesh of wire, a spiral wrap of copper tape, or a layer of conducting polymer, or some combination of those three constructions. The shield may be applied as the outside layer (just inside the jacket) for the entire cable – or there may be individual shields for particular groups of wires (typically twisted pairs) within the cable – or both.

If the control signals in a cable are sensitive to outside disturbance OR if they are expected to cause a disturbance themselves, OR if the installation is in an electrically noisy environment (such as a factory) it is wise to specify a shielded cable to maintain the highest degree of signal integrity along the length of the cable run.

In addition to specifying shielded cables – it is a good idea to become familiar with proper shield grounding techniques. In most installations, it is advisable to ground the shield of the cable at one end only – but there are certain situations that may require different techniques.

All Flexible Control Cable from Automation Direct are available with or without a shield. All control cable is available cut-to-length in one-foot increments, with very low minimum lengths.

What is the difference between cord and cable?

In the context of electrical power connections, these terms are used somewhat interchangeably in common speech, and both refer to a collection of electrical conductors that are enclosed in a single jacket. Cord usually refers to a connection that is either temporary or intended for frequent handling by factory personnel, while Cable is typically used to indicate a fixed or permanent power connections.

Automation Direct sells both Flexible Portable Cord and several types of cable intended for more permanent installations, such as VFD Cable and Continuous Flexing Motor Supply Cable.

All cord and cable is available cut-to-length in one-foot increments, with very low minimum lengths.

Why use VFD cable?

Variable Frequency Drives (VFDs) generate disruptive electrical noise in the environment around them. The noise emitted can affect other devices such as electronic equipment, commercial-grade Ethernet systems, and instrumentation wiring. Combined with proper grounding techniques, VFD cables are a key component to combat these problems with high-quality shielding, and insulation/cable construction rated for the extreme transient voltages that VFDs can produce.

Variable Frequency Drives (VFDs) generate disruptive electrical noise in the environment around them. The noise emitted can affect other devices such as electronic equipment, commercial-grade Ethernet systems, and instrumentation wiring. Combined with proper grounding techniques, VFD cables are a key component to combat these problems with high-quality shielding, and insulation/cable construction rated for the extreme transient voltages that VFDs can produce.

Grounding Configuration and Termination

An improper cable connected to VFDs creates noise-related issues within the system and improperly terminated cables can release captured noise current. AutomationDirect VFD cables offer both a ground conductor of equal to the size of the power conductors as well as separate drains for the shielding.

Proper Shielding to Contain Noise

To avoid noise problems, VFD cable needs to be effectively shielded. Research suggests that shielding systems that include a combination foil & braid types are the most appropriate for VFD applications. Automation Direct VFD cables include:

- 100% coverage aluminum/mylar/aluminum foil shield

- 85% coverage tinned copper braid shield

- Tinned copper drain wire(s)

Automation Direct offers VFD Cable cut-to-length in one-foot increments, with very low minimum lengths.

What does “Exposed Run” mean?

An “exposed run” of tray cable is any tray cable that extends from a cable tray or raceway to a mahine or other electrical device. Exposed runs of standard tray cable more than 6 feet long must be protected with conduit or additional raceway. However, there are special -ER cable types that can save significant installation costs – as they are allowed to extend as far as 50 feet or more from the cable tray if certain conditions are met:

- Exposed runs are only allowed in industrial environments which have qualified staff to maintain, supervise, and service the installation.

- The cable should be routed along existing machine supports and must be adequately protected by struts, channels or angles, and it must be secured at least once every six feet.

- Type TC-ER cables are required (by NEC) to include an equipment grounding conductor.

- Type ITC-ER cables are limited to an exposed run of 50 feet; PLTC-ER and TC-ER cable have no set length limitations.

These -ER cable types must meet additional crush and impact tests – but the ability to install them without conduit or raceway can offer significant savings: the cable itself is likely to be less expensive than an armored version of the same cable, and the cost and labor to run conduit or extend the cable tray may be eliminated.

Automation Direct offers Flexible Control Cable with multiple ratings and approvals, including:

- Type TC-ER (eliminates need for conduit/armor)

- Type MTW (meets NFPA 79)

- WTTC wind turbine tray cable

- Class 1 Division 2 hazardous locations

- Direct burial

- Wet and dry location

- Oil & sunlight resistant

All flexible control cable is available cut-to-length in one-foot increments, with very low minimum lengths.

What is the difference between ‘flexible’ and ‘flexing’ cable?

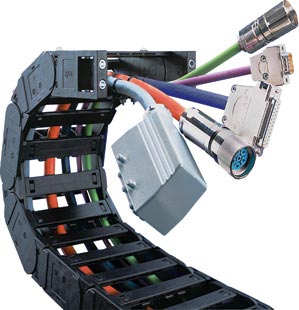

Flexing Cables are often installed in cable track (photo courtesy igus, inc.)

These terms sound similar, but they have specific meaning in terms of cable selection and application, Most all cable is ‘flexible’ to a certain extent, and it is designed to be bent and routed during installation. However, in applications that will require constant movement during everyday use or routine machine operation be sure to specify ‘flexing’ cable. Flexing cable is often used in cable track (c-track) to protect the cable and to regulate its motion path. Flexing cable will have a rating for the maximum number of bends over the lifetime of the product – usually several million cycles. Designers should also pay special attention to the minimum bend radius for flexing cable and make sure that the required radius for each application exceeds that minimum.

Automation Direct sells both Flexible Control Cable and Continuous Flexing Control Cable. Automation Direct also offers Continuous Flexing Motor Supply Cable and Continuous Flexing Industrial Ethernet Cable.

All flexible and continuous flexing cable is available cut-to-length in one-foot increments, with very low minimum lengths.

What do the letters on service cord mean?

Flexible portable cord (also called drop cord, service cord, or SO cord) can have long acronyms or partial part numbers associated with the various constructions. Service cord is available in a number of UL and CSA types including SO, SOW, SOOW, SJ, SJO, SJOW, STO and SJTO. Each letter of the cable type indicates a particular feature of the cable. For example: S = service (600 volts), SJ = junior service (300 volts), E = elastomer jacket, O = oil-resistant jacket, OO = oil-resistant insulation AND jacket, and W = weather resistant. Note: It’s confusing, but “Type W” is a different spec than the aforementioned “W” (see below).

Flexible portable cord (also called drop cord, service cord, or SO cord) can have long acronyms or partial part numbers associated with the various constructions. Service cord is available in a number of UL and CSA types including SO, SOW, SOOW, SJ, SJO, SJOW, STO and SJTO. Each letter of the cable type indicates a particular feature of the cable. For example: S = service (600 volts), SJ = junior service (300 volts), E = elastomer jacket, O = oil-resistant jacket, OO = oil-resistant insulation AND jacket, and W = weather resistant. Note: It’s confusing, but “Type W” is a different spec than the aforementioned “W” (see below).

Automation Direct currently sells:

- SOOW and SJOOW with a thermoset rubber jacket

- Best abrasion resistance

- Rubber, unlike plastic, is resistant to melting on momentary contact with a hot surface

- Lowest cost

- Temp Range: -40°C to 90°C (-40°F to 194°F)

- Available in 2, 3, and 4 conductors, from 18 to 10 AWG

- SEOOW and SJEOOW with a thermoplastic elastomer jacket

- Wider continuous temperature range

- Better flexibility at very low temperatures

- Temp Range: -50°C to 105°C (-58°F to 221°F)

- Available in 2, 3, and 4 conductors, from 18 to 10 AWG

- Type W has a chlorinated polyethylene (CPE) jacket

- Rated for heavy-duty service

- 2000 Volts

- Temp Range: -40°C to 90°C (-40°F to 194°F)

- Available in 8 AWG, with 4 conductors (only)

All service cord is available from Automation Direct cut-to-length in one-foot increments, with very low minimum lengths.

What types of bulk multi-conductor cable are currently offered by Automation Direct (9/25/2018)?

Flexible portable cord (also called service cord) is cable with multiple conductors used for electrical power connections requiring flexibility. Typical indoor and outdoor applications include wiring for industrial machinery, large appliances, heavy-duty tools, motors, and temporary electrical power and lighting for construction sites.

RS-485 & RS-422/RS-232 Cable (Bulk)

RS-485 and RS- 232 high-quality data cable helps prevent electrical noise problems in factory floor environments which can interfere with device-to-device communication circuits, causing delayed signals or data loss. These low-capacitance multi-conductor data cables with up to 3 twisted pairs are designed with impedances specific for RS-232/RS-422 and RS-485 communication applications.

Control cable is most commonly used to organize and simplify control signal wiring in facilities and during assembly of machinery. These flexible multi-conductor control cables have a premium-grade PVC outer jacket that is resistant to sunlight, oil, and moisture, making these cables ideal for wet or dry indoor locations as well as outdoor applications.

VFD cable is used to organize and protect the input and motor power wiring for variable frequency drives. It is specially designed to reduce VFD-related interference (EMI) on nearby equipment. These foil and braid shielded multi-conductor power cables have a black thermoplastic elastomer (TPE) outer jacket and offer 4 conductors in up to 2AWG wire size.

Instrumentation cable is typically used in industrial instrumentation, control, alarm, and energy management circuits. These UL ITC/PLTC listed instrumentation cables are available with up to 8 twisted pairs; overall shields with drain wire protect against electrical noise interference, while individually shielded pair models also protect against crosstalk.

Continuous Flexing Control Cable

Continuous flexing control cable is used to organize and simplify control signal wiring and is specifically designed for constantly moving applications such as robotic arms, or when installed inside C-track on moving equipment. These cables have a premium-grade PVC jacket that is sunlight and oil resistant, and flame retardant; ideal for wet or dry locations.

Continuous Flexing Industrial Ethernet Cable

Continuous flexing Ethernet cable is specifically designed for constantly moving applications such as robotic arms, or when C-track is used to provide Ethernet signals to moving equipment. Available in shielded or unshielded styles in lengths up to 1000 ft, this cable’s industrial jacketing has excellent weather and hazard resistance.

Thermocouple & RTD Extension Wire

Thermocouple extension wire is critical to maintaining signal integrity when extending thermocouple signals; specially constructed RTD wire offers superior performance compared to off-the-shelf cable. Extension wire is available in 50, 100 and 200-foot lengths, with various insulation types, an optional copper drain wire, and standard ASTM/ANSI color coding.

Note: We are always working to increase our product offering – so please click here to see the most up-to-date list of available types of Bulk Multi-Conductor Cable that we offer.

To read more Tech Topics, click here.