Closed-loop PID control is indispensable for a myriad of automation applications, and designers need to know the options for implementing PID using either dedicated devices or automation controllers.

Automated regulatory control of characteristics like flow, level, pressure, temperature, and many other types of analog values is essential for countless types of machinery, processing equipment, and commercial and industrial systems. The most common way to achieve this is with a proportional-integral-derivative (PID) control loop.

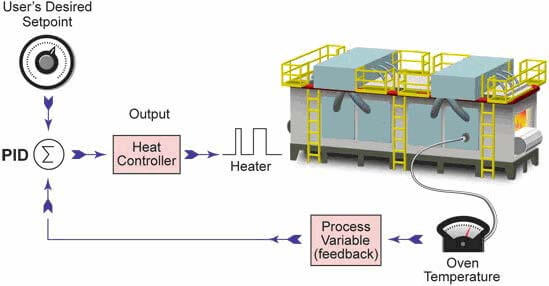

PID control monitors a process variable (PV) input, then commands a controlled output (CO), to achieve steady operation at the setpoint (SP). For some more detail on closed-loop PID control, check out this link for “What is PID Control?” The math behind PID control may seem intimidating, but the reality is that suppliers like AutomationDirect offer a wide variety of products to help users easily implement this high-performance control method.

Today’s designers have some choices about what types of PID controllers they select. The general choice is between relatively dedicated devices, or a more capable automation platform.

From Analog to Digital

The earliest PID controller devices were pneumatics-based, and they were often located in the field near the associated sensing and control device. The development of analog electronics provided an improved way to implement a PID controller, which would often be located in a control room panel.

However, the greatest advancement in this area was the development of digital electronics, because microcontroller- and microprocessor-based PID controllers were smaller, cheaper, more reliable, and far more capable than older technologies. While there may still be some limited applications for pneumatic PID controllers, almost all modern PID control is implemented with digital technologies.

Modern digital PID control can be accomplished with a dedicated PID-specific hardware controller, within other intelligent devices like a variable frequency drive (VFD), or with an even more capable programmable logic controller (PLC).

Evaluate the Application

Here are some basic questions to consider when specifying PID control:

- Is the application completely standalone or localized?

- Is there any need for local human-machine interface (HMI)?

- What types of alarming and historical data capabilities are needed?

- Should the control be integrated or supervised by other automation?

- Will more complex forms of PID control be employed?

- Would autotuning be desirable?

Dedicated devices for PID control

In very general terms, if an application is quite localized and standalone, there is a strong case to use a modern digital PID temperature/process controller. These will provide reliable control, along with a local HMI so users can monitor operation, and change tuning parameters and the setpoint. These types of local controllers can be very cost-effective.

Many versions of AC VFDs also include on-board digital PID functionality. This is a great all-in-one solution because many applications use VFD-driven pumps, fans, or other electric motor devices as the CO to regulate their operation, increasing/decreasing the speed so that the PV remains close to the SP.

Furthermore, some dedicated devices have very advanced options. They can trigger alarm contacts, log data, and communicate with other devices using serial or Ethernet media and other common industrial communication protocols. Considering this, sometimes the right choice is to provide local PID control with a dedicated device, but then to integrate it into a supervisory system.

PLCs for PID control

On the other hand, once an application grows a bit in complexity, with multiple loops and other industrial automation requirements, a PLC is often the logical choice. PLCs can control a number of PID loops, and users have the programming flexibility to integrate PID loops with each other, and with the automation of other devices.

For example, a single PLC monitoring a flow meter could control a VFD-driven pump to achieve a target product flow rate through a heat exchanger, while modulating a steam valve to achieve a desired product outlet temperature based on a thermocouple input. The PLC with an associated HMI would allow users to easily start, stop, monitor, and adjust this type of system.

Almost every AutomationDirect PLC includes the capability for PID control, although advanced models can do much more. Options include the CLICK PLUS micro modular, Productivity1000/2000/3000, BRX stackable micro brick, and more.

Get the Information You Need

The AutomationDirect website offers a comprehensive selection of dedicated process control and measurement devices and capable PLCs, so designers can find the best fit for applications both small and large. The site also includes plenty of information resources, specifications, documents/drawings, and videos—and support staff are ready by phone and email to help you find the right products for your applications.