Which is better? A DirectLOGIC style Do-more or the new Terminator I/O style Do-more?

The incredible power of the Do-more processor is now available in the popular Terminator I/O form factor. Functionally, both units have identical Do-more engines, so how do you know which one is better for your application? The answer is … It depends …

Under the hood

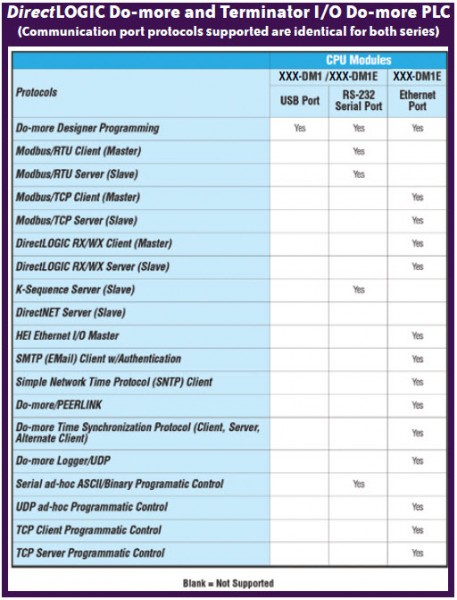

From a programming viewpoint, the two CPUs are, for all practical purposes, identical. Both have the same flexible memory management, same ease of use, same built-in free simulator, the same easy-to-use instructions, the same programming environment, and the same strong data typing, They both have the same built-in serial port and Ethernet port options and they both use the same Do-more Designer software.

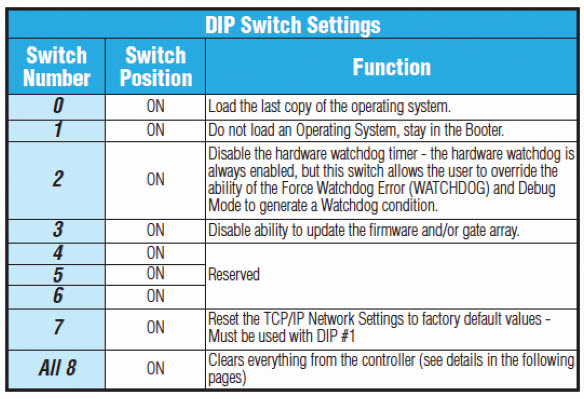

Both processors have the same configuration dip switches …

[/two_columns] [two_columns_last ]

[/two_columns] [two_columns_last ] [/two_columns_last]

[/two_columns_last]

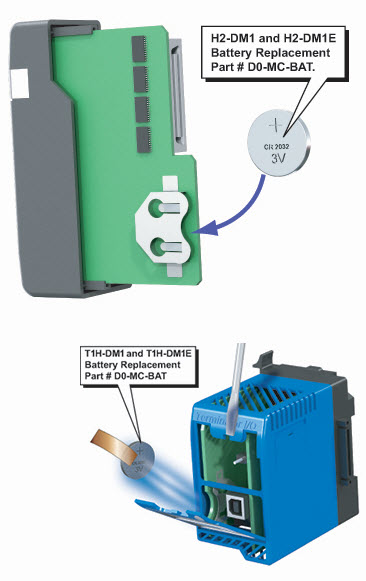

and even use the same backup battery:

And on both controllers, if the backup battery needs to be replaced, the PWR LED will be YELLOW instead of its normal GREEN color and the system bit location $BatteryLow (ST149) will be ON.

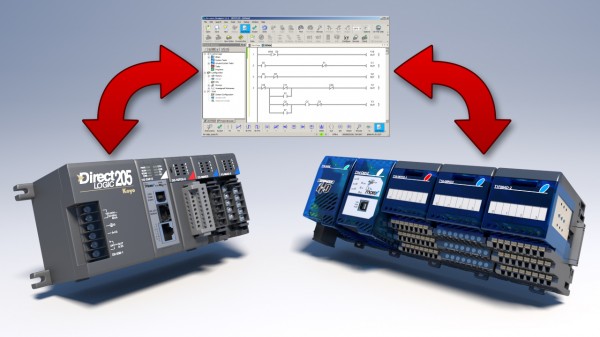

They are so similar, that you can even develop your ladder code on one and then deploy it on the other.

How to Choose

If they are so similar, how do you choose between them? For most applications, either will do just fine. There are a few applications where one provides a definite benefit over the other, though.

In general, if you are doing everyday PLC control applications, you’ll find the DirectLOGIC platform will be the most straightforward and may cost a little less too. With the DirectLOGIC platform, additional serial ports and Ethernet ports can easily be added – the Terminator version does not offer those types of modules.

The Terminator style may be a good choice if you have a lot of analog I/O. Terminator I/O has a much higher analog I/O density than the DirectLOGIC platform, which can make Terminator more cost-effective with that type of I/O mix.

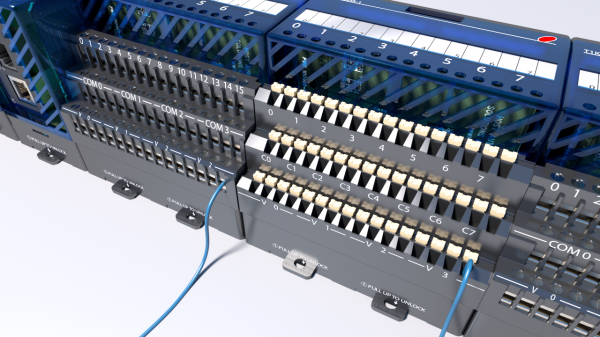

A huge advantage of the Terminator I/O form factor is that all three connections for power, ground and signal are on the module; you do not need the extra footprint to wire to external ZIPLink wiring modules or individual terminal blocks.

Another footprint savings you get with the Terminator I/O is when it comes time to add another power supply because you ran out of current to drive all the sensors. With the DirectLOGIC platform, you would have to add another external power supply and another row of DINnector terminal blocks and extra wiring to get power to all of the sensors.

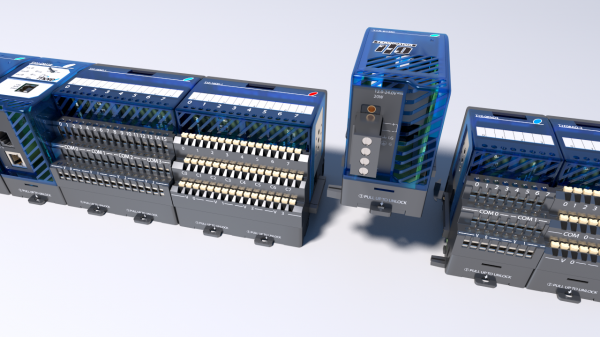

With the modular design of the Terminator I/O, you simply drop another power supply in line at the end of the existing modules and continue adding I/O modules as needed.

Since the Terminator platform is “stackable” – no I/O racks, just add a module at a time – it can be more flexible when needing to expand the system.

The Terminator has another unique advantage: you get to choose the type of terminal connection you prefer – screw terminal or spring clamp. This is really a personal preference, but for those who like spring clamps for quick, easy and reliable wiring connections, this is a big deal.

Either Do-more PLC will likely do the job; most important is determining what types of I/O and communications you need and ensuring that your preferred platform supports those.

Originally Posted: March 19, 2014