The goal of any technology or engineering educational program is to educate its students utilizing techniques built upon sound theoretical principles. But, how does one teach college level students to utilize automation components like robots, PLC’s, and sensors?

The field of automation is constantly changing and educators need to maintain pace with these changes in the classroom, in order to produce well-qualified graduates. The real solution to this complex situation is through innovative Industry/ Education partnerships.

Innovative Industry/ Education Partnerships

The teaching of advanced hands-on concepts requires complex laboratories and equipment. As the level of state funding decreases in higher education and technology usage increases, universities are looking towards new avenues to develop experiential learning facilities. This is especially true in the area of Technology, which is heavily dependent upon maintaining laboratories which keep pace with industry changes.

As the name Technology implies, students must enter the workforce with the hands-on laboratory skills that are needed in industry. The Northern Illinois University Department of Technology has the same set of challenges in developing and/or modernizing laboratories in the automation areas; the biggest challenge is finding the needed funding.

Through a large alumni and industrial support base, the department has made strides in modernizing laboratory facilities in the manufacturing and electrical areas.

During the past five years, Automation Direct has provided equipment, including PLCs, to the department. However, the company made an even bigger commitment to the students. AutomationDirect recognized that if students use their equipment in the course of instruction, they will be more inclined to use this equipment at their companies upon graduation. This understanding has proven to be true over and over again with NIU graduates.

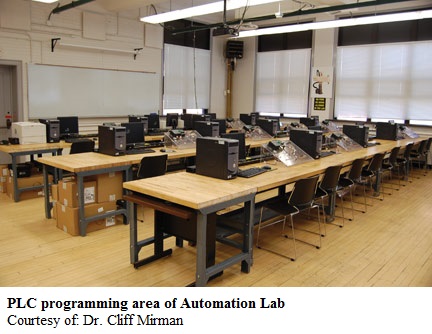

In 2008, AutomationDirect partnered with NIU’s Department of Technology to help fund a well-equipped automation laboratory. In return for the support from the company, the Northern Illinois University Department of Technology named the lab the AutomationDirect Automation Laboratory. Through funding and equipment provided by AutomationDirect, the NIU Department of Technology can now keep this important laboratory current in equipment and process.

In 2008, AutomationDirect partnered with NIU’s Department of Technology to help fund a well-equipped automation laboratory. In return for the support from the company, the Northern Illinois University Department of Technology named the lab the AutomationDirect Automation Laboratory. Through funding and equipment provided by AutomationDirect, the NIU Department of Technology can now keep this important laboratory current in equipment and process.

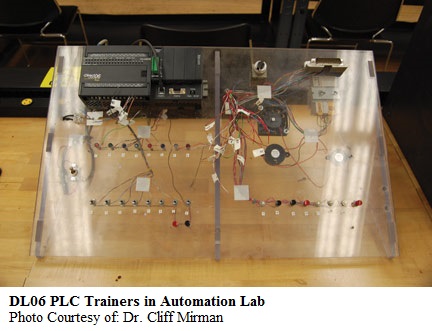

This laboratory supports the departmental Programmable Logic Controller (PLC) course and the Automation course. The PLC course teaches students basic and advanced concepts and applications for PLC programming. In addition, the students learn to integrate various components with the PLC, such as sensors, switches, and output devices, as shown above.

This laboratory is also used to teach the departmental automation course, where students learn basic concepts of robotics, vision, and pneumatic control, as well as integration of the components learned in the PLC course.

As a final project, student teams design automation systems which will sort parts, using the integration of vision, PLCs, sensors, and pneumatics. This level of experimental interaction produces Manufacturing Engineering Technology graduates who excel in industry.

In addition to student instruction, AutomationDirect and the NIU Department of Technology are exploring new ways to best use this laboratory to assist the company. The Department faculty will use the facility for industry training courses on the AutomationDirect PLC products. Through the gracious assistance from AutomationDirect, the school will have a very strong laboratory facility in which the next generation of manufacturing engineering technologists will be educated.

In addition to student instruction, AutomationDirect and the NIU Department of Technology are exploring new ways to best use this laboratory to assist the company. The Department faculty will use the facility for industry training courses on the AutomationDirect PLC products. Through the gracious assistance from AutomationDirect, the school will have a very strong laboratory facility in which the next generation of manufacturing engineering technologists will be educated.

View products from AutomationDirect that relate to this article: DirectLOGIC DL06 PLCs ׀ DirectSOFT PLC Programming Software

By Cliff Mirman, Ph.D.

Professor and Chair,

Department of Technology

Northern Illinois University

Originally Published: Sept. 1, 2008