As technology advances, so does the speed at which it communicates. And with the advances made in industrial controls, the need for high-speed data transmission became a priority. As a result, Ethernet communication became more and more prevalent in industrial networks and prompted many industrial equipment manufacturers to implement their own Ethernet communication protocols. These protocols, some proprietary, were needed in order to properly organize the data transmitted to/from a manufacturer’s equipment. Modbus TCP/IP was one of the first Ethernet protocols developed since it already had roots in serial communication. Modbus TCP/IP, originally developed by Schneider Electric, is basically the Modbus RTU serial protocol inside a TCP/IP wrapper. The TCP/IP protocol layers allow the Modbus data to be carried over the Ethernet network. Eventually, other Ethernet protocols were developed including: EtherCAT (originally developed by Beckhoff), Profinet (originally developed by Siemens) and EtherNet/IP (originally developed by Rockwell).

Top 3 Ethernet Protocols

- Ethernet/IP

- Profinet

- Modbus TCP/IP

The number one spot currently belongs to EtherNet/IP and it has a strong presence in both America and Asia. This protocol also has the backing of the Open DeviceNet Vendors Association (ODVA) which is a global association of automation companies with a common interest in communication technology. This association is responsible for managing the EtherNet/IP industrial Ethernet protocol and promoting conformance across multivendor systems.

What does this mean for you?

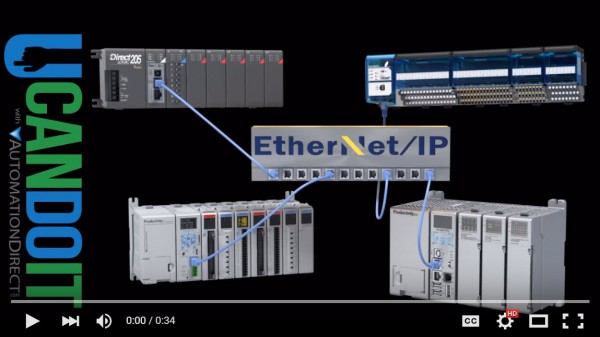

As the industry settles on common protocols for Ethernet communication and with EtherNet/IP currently in the top spot, more and more manufacturers will deploy this protocol in their products. If you take a look at our PLC lineup, you’ll see that EtherNet/IP has been incorporated into both the Productivity Series and Do-more line of controllers. These controllers utilize the explicit and implicit messaging techniques of EtherNet/IP to optimize data exchanges across the network. In English, please! Ok sure, with explicit messaging the data messages that are transmitted will contain everything needed in order to respond or decode the message. It is a normal client/server relationship with instructions explicitly spelled out in the data messages. The client basically says, “Server, I need this information, formatted exactly as specified in this message, please send it.” The server then responds with a message containing the formatted information. With implicit messaging, the data messages are streamlined without the excess baggage because each device is configured ahead of time to know what to do with the data. This is great for time-critical messages and it functions like a typical scanner/adapter relationship. This real-time messaging basically copies data with minimal additional information because both ends already know exactly what each bit and byte mean.

Building the EtherNet/IP standard into these controllers allows you to choose the messaging method that is most efficient and meets the speed requirements of your applications.

Get the whole story…

So, if you haven’t worked with the EtherNet/IP protocol, you probably will soon enough. And what was discussed here is just a piece of what this protocol is all about. Actually now that I think about it, EtherNet/IP would really be better demonstrated with a video or two…or three…or more. To learn more about EtherNet/IP and how it is used, check out the EtherNet/IP chapter in our Automation Video Cookbook. There are “Tech Tip” videos that provide an excellent introduction to EtherNet/IP messaging, explaining in simple terms that are easy to grasp. The “How To…” videos demonstrate the EtherNet/IP implicit and explicit messaging concepts using Do-more series PLCs and Productivity series PLCs with a wide variety of EtherNet/IP compatible hardware – Allen Bradley Flex Drives, Datalogic bar code scanners, AMCI encoders, Advantech Adam I/O modules, etc. As an added bonus, the Do-more videos also show you how to use the built-in simulator to practice using EtherNet/IP messaging without actual hardware in hand. I know, I know, awesome, right?

Read more Ethernet/IP articles.