Robust real-time industrial control is essential, and remote connectivity is also becoming indispensable for many users. Here are some considerations for achieving the best of both worlds.

Damon Purvis at AutomationDirect wrote an article for the February 2023 issue of Processing. Titled Balancing Local Automation with Remote Connectivity, this article explores some concepts around designing industrial automation systems, while including secure IT and cloud connectivity.

Because networking, cloud connectivity, and cybersecurity are increasingly important for all types of industrial, commercial, and even personal technology solutions, users and designers are looking for the best ways of combining traditional operational technology (OT) systems with modern IT capabilities.

IT/OT: Cooperation or confrontation?

Typical OT-centric PLCs and HMIs used for traditional industrial automation systems in years past were very localized, with limited connectivity options. More modern versions have improved IT-focused networking and cloud connectivity. Now, IT and OT are converging, and more changes are underway.

Sensing the demand, large organizations like Amazon, Google and Microsoft are entering the industrial space with various internet of things (IoT) innovations. However, they remain largely IT-focused, with an emphasis on data scientists and other IT types of users. Many manufacturer sites do not employ this type of staff, and the local OT users need solutions that are easy enough to operate — and even deploy — with the personnel they have on hand.

It is important that IT/OT convergence proceed in a cooperative rather than a confrontational manner, as there are many use cases requiring the use of technologies in both areas. For example, both IT and OT technologies are needed for best performance when connecting large numbers of smaller and more localized machine-level data sources to higher-level computing for analytics and other purposes.

In the cloud and on the ground

Purely cloud-based solutions are most suitable for applications that are less real-time, such as advanced analytics. Edge computing power is increasing so more analytics can be performed in OT systems, but efficient connectivity to the cloud is still desirable. Designers need to strike a balance between local computing/control, and higher-level networking/processing.

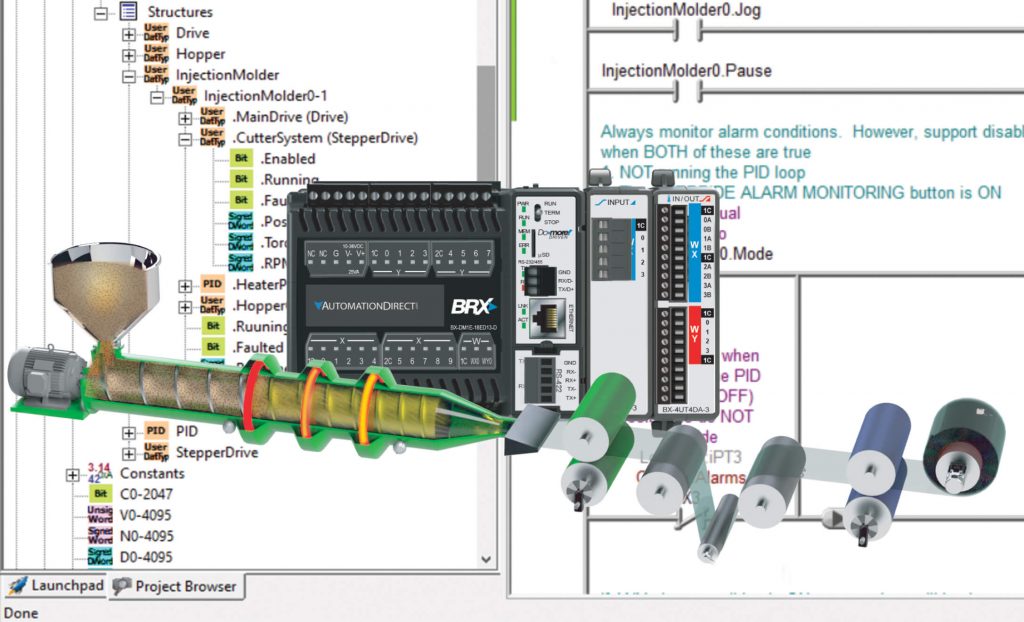

To address these and other issues, AutomationDirect offers a complete portfolio of modern PLCs providing robust machine control, with built-in capabilities to extend connectivity within a plant and up to the cloud. Users can choose from AutomationDirect CLICK PLUS PLCs, Productivity1000/2000/3000, BRX, and more to accomplish their goals.

The PLCs all use industry standard protocols and methods. Depending on the model, these include HTML5, OPC-UA, HTTP(S) via REST API, and MQTT to provide secure and flexible communications, even over the low-bandwidth or intermittent connections typically found in factories and manufacturing sites.

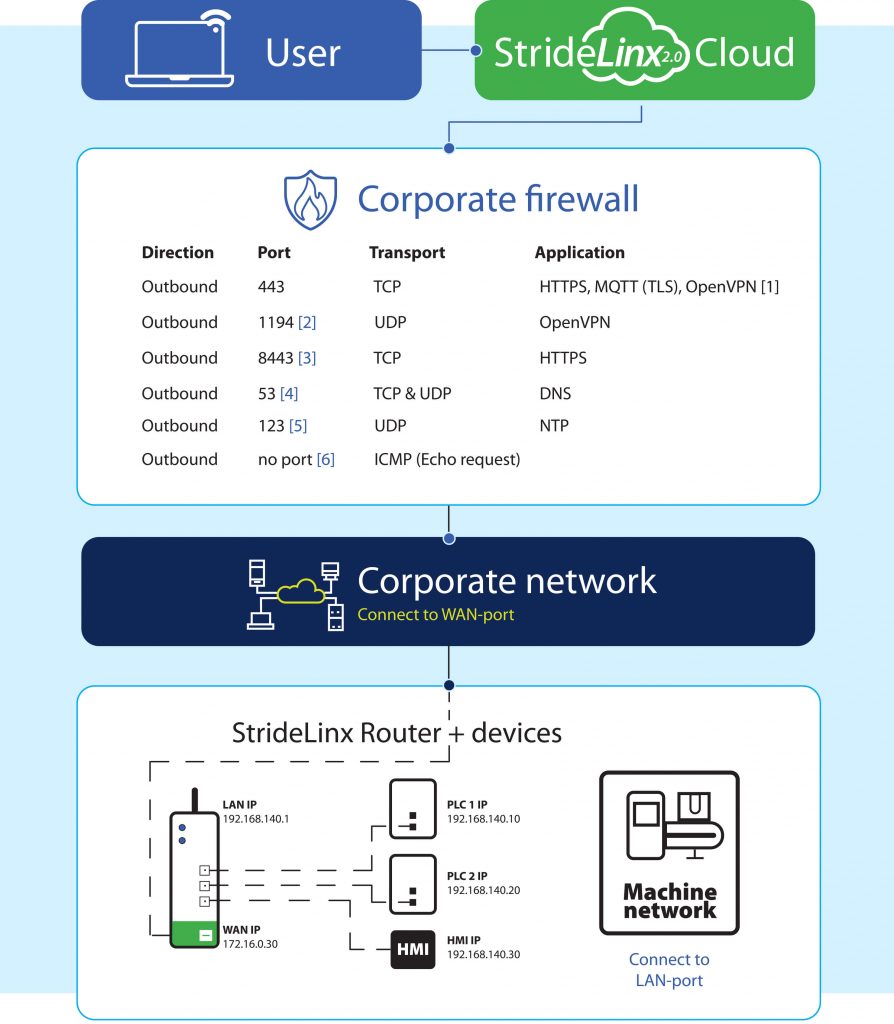

Modern automation solutions are less likely to be purely local than in years past, yet they also cannot lean too heavily on remote functionality. Users and designers can find the right balance for their applications by developing architectures based on proven OT products that incorporate IT-friendly features. StrideLinx industrial VPN routers and cloud IoT platforms, both offered by AutomationDirect, provide the next step for connecting the field to the cloud.

Visit the AutomationDirect website to explore the complete portfolio of linear actuators, servos, steppers, motion controllers, and PLCs.