Maker hardware and software is now available in industrially-hardened form factors, adding the reliability required for critical applications.

Bill Dehner, technical marketing engineer for AutomationDirect, wrote an article for the May 2020 issue of Control Engineering titled Open-Source Benefits for Industrial Controllers. Here’s a summary, click on the link above for the full text.

Industrial technologies tend to develop slower and lag behind consumer tech, but that gap is closing. For instance, in the consumer world over the past 15 years a “maker” culture of users creating homebrew automation project with open source controllers and methods has gained momentum. In an example of reduced time-to-market, new industrialized microcontrollers are now enabling users to combine open source ingenuity with proven industrial platforms.

From PLCs, to PACs, to Open

Programmable logic controllers (PLCs) are well known for their compact and robust industrial automation feature set. Improved hardware and software technologies led some vendors to begin marketing their most capable PLCs as programmable automation controllers (PACs).

Today, many small field sensors and devices have gained intelligence, and collectively make up the industrial internet of things (IIoT). The capabilities of industrial-specific PLCs, PACs, and IIoT devices now overlap to some extent.

Adding Open Source to the Mix

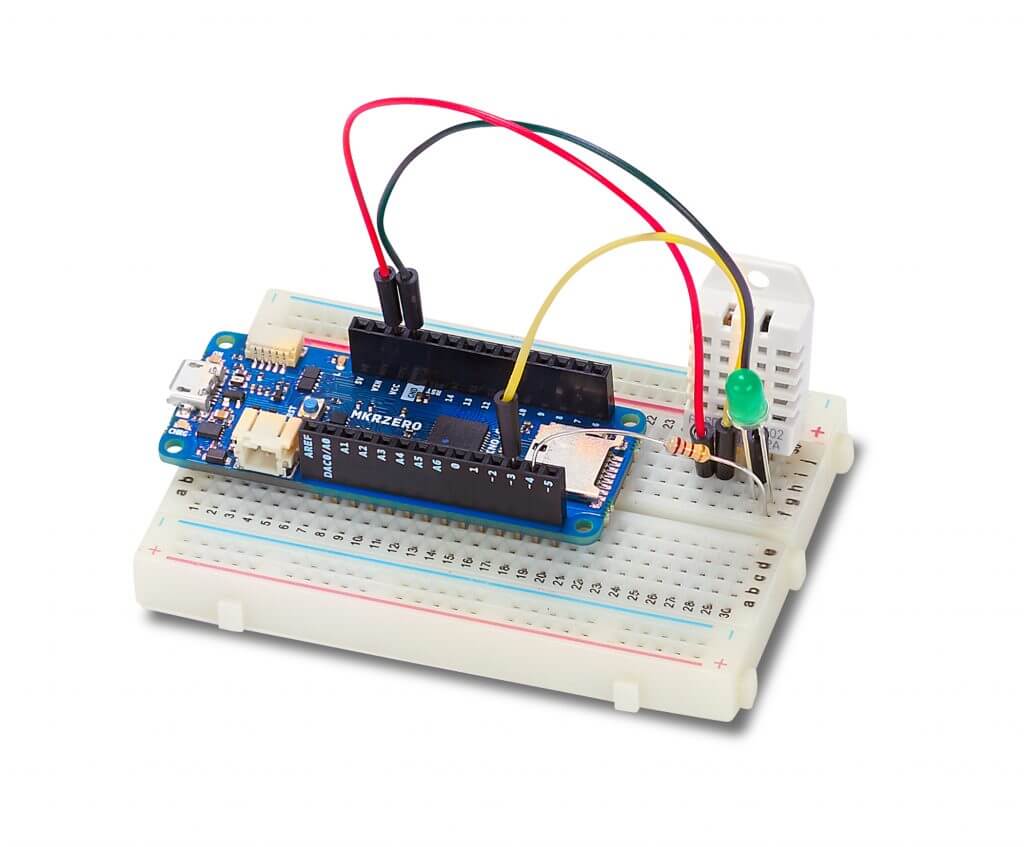

Today’s users are much more likely to be comfortable with the common open source Linux operating system, and with using code snippets or entire program segments available from online libraries created by other users. Hobbyists are flocking to open hardware microcontrollers like the Raspberry Pi and Arduino. Both are inexpensive and easily accessorized.

While these devices are popular, they were largely created for prototyping and educational projects. However, the industrial automation industry has taken notice.

Recognizing Open Source Risk

Standard open source platforms have many issues impacting suitability for industrial projects:

- Unprotected circuits

- Not built for or tested within industrial environments

- Lack of standard I/O signals

- No approvals or certifications

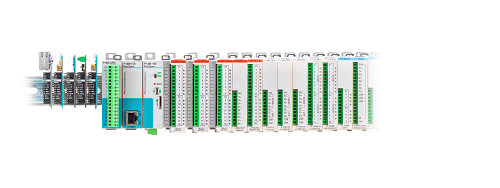

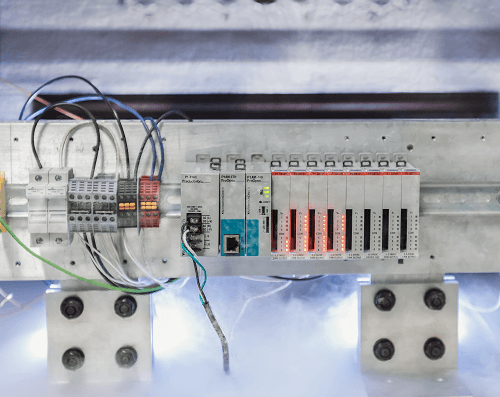

To address these and other issues, AutomationDirect has packaged open source elements, such as an Arduino controller, into industrial form factors.

The AutomationDirect ProductivityOpen not only gives users industrial-grade access to an open source microcontroller, it also marries it into a form factor compatible with proven modular I/O. Users can also incorporate standard commercial or industrially-hardened add-on “shields” for increased functionality. Unlike consumer-grade products, the ProductivityOpen line is tested in extreme conditions to ensure reliability, just like AutomationDirect’s PLCs.

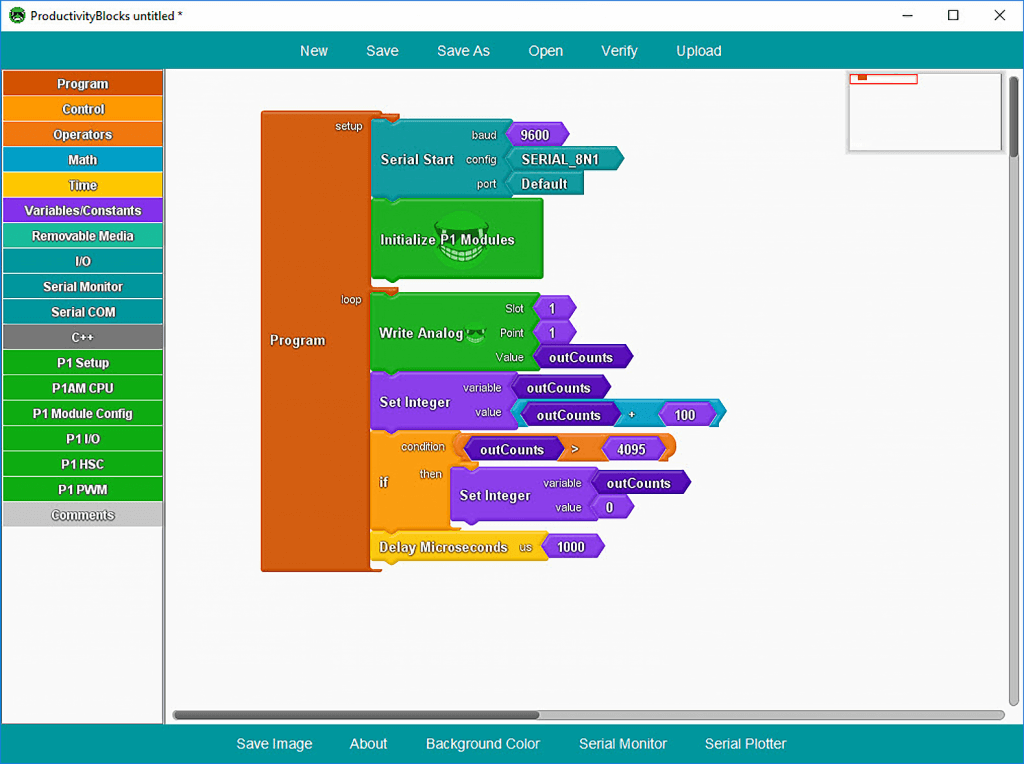

Developers can use the typical Arduino sketch software interface to program in C++, or they can take advantage of the AutomationDirect ProductivityBlocks graphical programming interface which simplifies many common tasks.

With open source, users have more options to mix-and-match hardware and software. A new generation of users is more comfortable with contemporary technologies as opposed to traditional platforms, and ProductivityOpen is a way to bridge open source with proven technology, and to grow technical staff with new employees.

Benefits and Applications

Industrialized open source automation can be useful for OEMs, semi-industrial applications, or consumer-oriented projects where reliability is key.

For instance, a gardening hobbyist might configure a microcontroller to operate the vegetable hothouse and irrigation in their backyard. At work they could use these same concepts to automate much larger scale agricultural systems and equipment. Similarly, someone using a microcontroller in their home to remotely control light and other devices could extend the same concepts to automate lighting and environmental controls at commercial or industrial facility.

Consumer-grade open source can be a tempting low-cost choice but may become a drain on support budgets. Industrialized open source can deliver the modern automation options users want and the reliability they need.

Originally Published: 5/2020