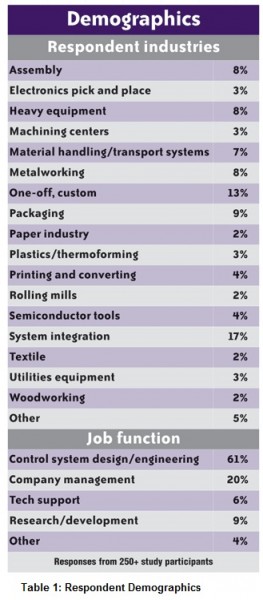

Machine and robot builders are increasingly turning to the Internet for product research. The Internet has become a legitimate avenue for researching automation products needed by machine and robot builders, and the use of vendor websites is emerging as the primary method for doing product research. Control Design magazine began asking its readers about their product research and buying preferences in 2006.  The results of the annual survey appear in the magazine (and online)—highlighting product research trends, issues and occasional surprises. In 2007, the magazine began including questions about use of videos, podcasts, blogs, and webcasts. This year, the magazine asked about social media as an information delivery tool. The respondent demographics for this year’s survey are listed in (Table 1).

The results of the annual survey appear in the magazine (and online)—highlighting product research trends, issues and occasional surprises. In 2007, the magazine began including questions about use of videos, podcasts, blogs, and webcasts. This year, the magazine asked about social media as an information delivery tool. The respondent demographics for this year’s survey are listed in (Table 1).

Changing Preferences

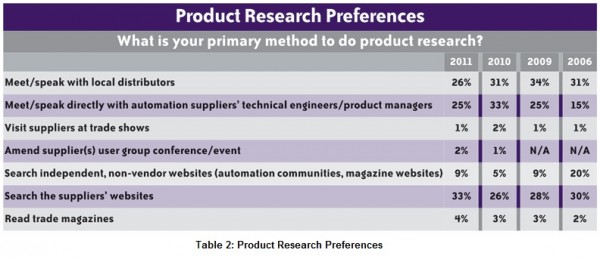

Control Design always asks the study participants about their primary method for doing product research. “For the first time since we began this annual study, the use of vendor websites significantly outpolled the use of local distributors as the single most-preferred product research method,” said Joe Feeley, editor-in-chief and author of Control Design’s March 2011 cover story, “Sign of the Times.” “Meeting directly with the manufacturers’ product experts took a significant dip, returning to 2009 levels,” added Feeley. The survey results reveal some differences among the age groups. In response to the question: “What is your primary method to do product research?”, the findings were that: “Overall, 33% said searching supplier websites is their primary method,” observed Feeley (Table 2). “But 44% of the 30-39 year-old group noted that as their primary method, compared with 28% of the 40-49 year-old group and 37% of 50-59ers,” said Feeley.

“Speaking/meeting with local distributors (26% overall) was the primary method of 44% of the 40-49ers, but only 24% of the 30-39ers, and 19% of the 50-59ers said it was their primary method,” summarized Feeley.

Previous surveys show that most respondents use global search engines such as Google when they don’t go to a supplier’s website first. Recent trends indicate slightly more satisfaction with this method than before (Table 3).

“For the first time, less than half the respondents agree with the statement that global search turns up too many outdated results. In 2008, 61% agreed with the statement,” Feeley said in the cover story.

“One reason for the overall better search experience is 90% of the respondents agree with the statement that they’ve gotten better at search strategies and techniques. Also, in 2008, 78% agreed that the results at the top of a search list were probably bought and paid for, regardless of relevance. This year, that sentiment is shared by only 64% of respondents,” added Feeley.

Supplier Website Usefulness

Although more machine and robot builders are using supplier websites to do product research, some vendor websites don’t make the cut. The Control Design survey asked questions about what makes supplier websites useful, and what makes a website bad.

“First, give me ready access to all pricing information, even if it is only a nominal list,” said John Raynes, owner of Raynes Engineering, Torrey, Utah, (www.re-solar.com) in the cover story. “I want to know within a minute or two if we’re even in the ballpark before spending more time. Second, I want ready access to all relevant product information (datasheets, manuals, etc.) in PDF format.”

In the cover story, Feeley said that about 15% of those responding to their open-ended questions about good and bad vendor websites cited having to register as a negative, many calling it a reason to leave and not revisit the site. Many others said they’re turned off by “too much marketing stuff before you can find the product info and specs.” They also are wary of sites with unsubstantiated product performance claims.

Many of those responding to the Control Design survey want easier, faster access to product pricing and they don’t want to jump through hoops to get there. “Don’t make me register/login just to browse basic catalog information,” Raynes continued in the cover story. “I don’t mind giving my name and simple contact info, but creating a login account when I don’t know if I’ll ever be back is just stupid.”

Another annoyance is “elaborate, showy Web animation that slows down the process of getting to the relevant information quickly,” noted Feeley.

The State of Supplier Relationships

Meeting with a manufacturer’s product expert or local distributors used to be how most machine and robot builders learned about products. However, maintaining distributor relationships is giving way to product pricing.

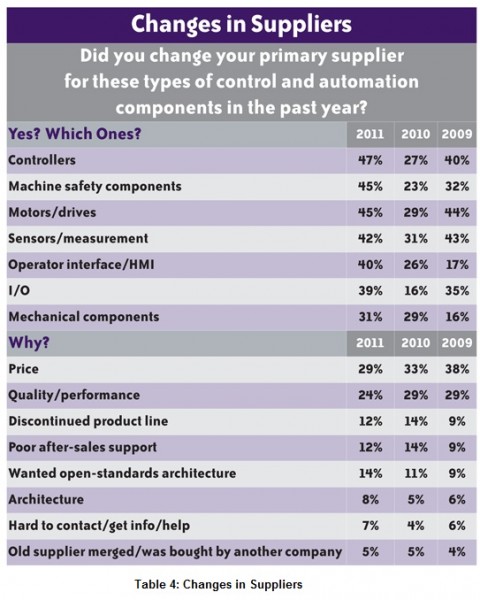

In its annual survey, Control Design asks questions that gauge the stability and volatility of the relationships between survey participants and suppliers. Survey results show that consistently more than half of the respondents changed suppliers for at least one primary automation component.

In its annual survey, Control Design asks questions that gauge the stability and volatility of the relationships between survey participants and suppliers. Survey results show that consistently more than half of the respondents changed suppliers for at least one primary automation component.

Although 55% of the respondents said they made at least one change in the past year, the survey indicates increased stability (Table 4). “This is less churn than the 59% we found last year, and the troubling 62% from the 2009 study results,” the cover story said. “Although fewer changed suppliers, those that did made changes in more product categories than last year, and comparable to the 2009 churn that was more price-related than anything else.”

According to Feeley, “Some 72% of the 20-29 year-old group of participants said they changed a major supplier in the past 12 months, compared with 56% of the 30-39 year-olds and 52% of 50-59 year-olds. The 30-39ers and 50-59ers indicated that they on average changed suppliers in 3+ product categories, while the 40-49ers averaged just over two product category supplier changes.”

Product pricing still dominates. “Price still is the biggest change agent, but it declined to 29% from 33% in 2010, and 38% in 2009, during the economic meltdown when cost-cutting pressures were even more rampant than usual. Poor quality/performance was noted by fewer (24%) responders than previously,” continued Feeley.

“With some relief from the pricing pressure, we find upticks of poor after-sales support causing users to switch,” the Control Design cover story said. “Although only 14% of the respondents say they changed suppliers because of it, that’s twice the rate of 2008. After price and quality/performance, 19% of the 40-49ers noted poor after-sales support as their reason to change suppliers, compared with only 7% of the 20-29ers and 9% of the 50-59ers.”

Internet Importance Increasing

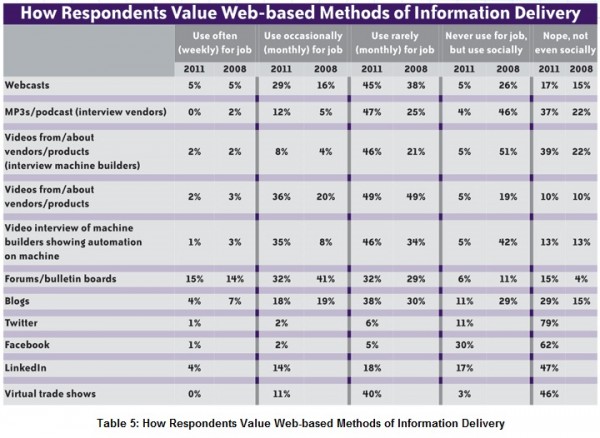

While searching supplier websites is apparently emerging as the primary product research method for machine and robot builders, vendor sites are not the only information-delivery tools. The Internet continues its evolution by delivering Web-based tools such as webcasts, podcasts, videos, forums and blogs. Emerging social media such as Twitter, Facebook, and LinkedIn are among the latest information avenues included in the Control Design survey (Table 5).

According to Feeley’s cover story, some of the choices in digital tools show a slowly growing trend. “In 2008, 16% of respondents said they used webcasts occasionally,” the Control Design story said. “This year it’s 29%—and that’s a bump of 6 points compared with 2010, with the biggest support (44%) coming from the 30-39 year-old study participants. Although there’s been no change in those who claim more frequent use than monthly, those who say they have never used webcasts for their job dropped to 5% compared with 26% in 2008.”

According to Feeley’s cover story, some of the choices in digital tools show a slowly growing trend. “In 2008, 16% of respondents said they used webcasts occasionally,” the Control Design story said. “This year it’s 29%—and that’s a bump of 6 points compared with 2010, with the biggest support (44%) coming from the 30-39 year-old study participants. Although there’s been no change in those who claim more frequent use than monthly, those who say they have never used webcasts for their job dropped to 5% compared with 26% in 2008.”

According to the cover story, an open-ended question about which of these delivery vehicles provides the most help made it clear that the participants overwhelmingly prefer an on-demand webcast option. However, it also revealed worries about webcast events—whether live or on demand—being just a product fluff piece keep many of the respondents from trying them out.

In the cover story, the thoughts of many of the survey’s responders are summarized by the comments of one of the participants: “Webcasts are good, but they take a long time, they’re usually biased towards a certain vendor, and they often trigger a flood of junk email after you register for one. Forums and bulletin boards are often outdated and not moderated, so there’s a lot of bad information out there from self-proclaimed ‘experts.’ We’re not allowed to use Twitter/Facebook/LinkedIn on the company network. Technical information/videos/manuals from the manufacturers and vendors are usually the most current, relevant sources of information.”

Emerging social media has been slow to catch on as an information delivery tool. According to the Control Design cover story, almost 80% of the respondents don’t use Twitter for any purpose, and only 3% report occasional or more frequent use.

Feeley’s article said that Facebook shows similar results, except three in 10 do say they have Facebook activities outside of their jobs. “As more companies raise their visibility via Facebook, perhaps we’ll see an increase in job-related activity moving forward more quickly than the other digital tool options have. It’s only among the less-than-40-year-old respondents that we find any (12%) weekly job-related Facebook use,” the article said.

However, there’s evidence that companies are using social media to reach out to current and potential customers. “As an electrical and controls engineering consulting firm, social media allowed us to reach out to clients locally, and prospective clients outside our usual territory of the Pacific Northwest,” says Josh Sherman of Trindera Engineering (www.trindera.com), Coeur d’Alene, Idaho, in the cover story.

“Our company shares current projects, services, presentations, photographs, and fliers on Facebook, Twitter, and LinkedIn. Followers view our posts and comment that they weren’t aware Trindera worked on a certain project or provided a certain service, and new teaming arrangements are born,” added Sherman.

According to the Control Design story, Sherman noted that Trindera attempts to help educate its followers using social media for upcoming presentations, lessons learned, technical tips, and promoting seminars such as Arc Flash or others that it hosts.

“Lessons learned, tips for contractors on our projects, and customer appreciations are all key factors in what we try to do using Facebook,” he said. “Twitter, we use as a tool to reach out to fans, letting them know what we are doing and what we can do for them, as well as sharing information in a real-time method,” concluded Sherman.

Although 90% of respondents don’t use podcasts—even occasionally—the frequency of use among those who do has doubled since 2008. “Those who stated no use at all plummeted from about half the respondents in 2008 to around 5% this year,” the cover story said.

The jury is still out regarding blogs. According to the cover story, blog use is age-dependent, while the four-year trend remains mixed. “Although this group of respondents still makes little regular use of them, the group that says it uses blogs at least once or twice a year has grown to nearly 40% from 30% in 2008, mostly drawing recruits from the group that said they never used to use blogs for their jobs. The ‘never’ group stands now at 11%, a significant change from 29% in 2008. Only 6% of the 50-59ers use blogs occasionally or more, compared with 32% of 40-49ers and 42% of the 30-39ers,” said Feeley’s in the cover story.

According to the story, product videos and machine automation videos have a long way to go before they’ll be considered a mainstream tool for this audience, but use at an occasional level has grown to more than one in three, compared with about one in seven in 2008.

Article originally published as the Control Design magazine, March 2011 issue cover story.

By Jack Smith

Originally Posted: Sept 1, 2011