PLC Speaking has something new and exciting to talk about. AutomationDirect® and our parent company KOYO Electronics have released a new line of stackable micro brick PLCs – the truly innovative CLICK™ PLC. You get a stand alone CPU/PLC with eight digital inputs and six digital outputs which is easily expandable up to 142 I/O.

The CLICK PLC

Our objective with this product was to strengthen our low-end PLC offering. Small systems integrators and original equipment manufacturers who have not previously considered PLCs for their projects and/or applications may find this a very attractive solution.

We realize one of the biggest deterrents for trying a new PLC control platform, or simply getting started with PLC control, is the cost. This is why we feel CLICK is the perfect PLC for most small applications.

The customer’s learning curve is by far the greatest cost when starting a new control platform. The CLICK PLC programming software is a FREE download from our Web site, so there is no additional ‘getting started’ cost, no purchasing an expensive programming tool or recurring license fees and maintenance agreements. However, unlike many “FREE” programming packages, this fully-functional software is packed with features to shorten your learning curve and reduce your programming time.

The customer’s learning curve is by far the greatest cost when starting a new control platform. The CLICK PLC programming software is a FREE download from our Web site, so there is no additional ‘getting started’ cost, no purchasing an expensive programming tool or recurring license fees and maintenance agreements. However, unlike many “FREE” programming packages, this fully-functional software is packed with features to shorten your learning curve and reduce your programming time.

One of the many remarkable features is the reduced instruction set of 21 simplified, yet powerful programming instructions. Some people look at this and immediately suspect that this product cannot possibly satisfy their application needs with so few instructions. I challenge anyone to download the free programming package and see just what CLICK can do.

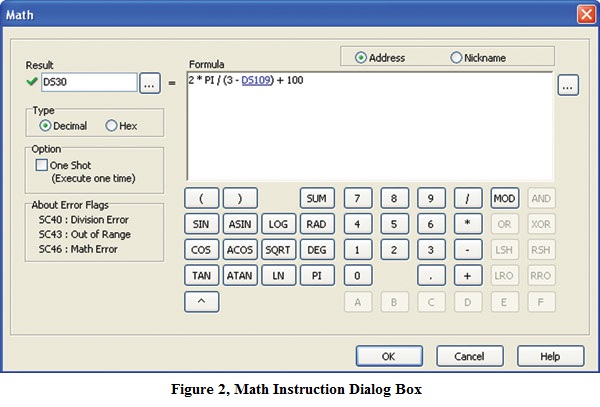

Like the CLICK hardware, the instruction set was designed with the customer in mind. You will find contacts, coils, set, reset, counters and timers, just as you would expect. However, what will astonish you are the function block designs. For example, the math instruction (Figure 2) easily adds two data registers, and also allows for free form entry of parenthetical expressions which can be nested up to eight levels. A complex expression such as DS25^(2*DS87)+DF11*(1000-50)/4095*PI can combine multiple data types, and constant value with algebraic and transcendental operators. (Trigonometric functions can be solved in radians.)

That’s just the math block. We have applied that same mentality to our timers (Figure 3) and counter, making it extremely simple to accomplish what you need with one instruction, whether an on-delay or off-delay, retentive or non-retentive, count up, count down, or both, etc. Simple selections within the instruction allow you to do exactly what you want to accomplish without having to search for the right instruction.

The Copy instruction (Figure 4) can move data, copy, block copy, pack or unpack words; it all depends on what you want to do. Plus, our graphical selections make your decision process super fast.

The CLICK Windows-based programming environment is intuitive and familiar if you have used our C-more products (Figure 5). The navigation pane provides quick and easy access to the most commonly used menu items required for designing, commissioning and troubleshooting a project. You can simplify program file management by using main program, sub-routine and interrupt program files, allowing you to easily see and organize all program files.

If you are familiar with DirectSOFT®, you will see tools which you are accustomed to, such as the DataView for monitoring real time data in your project, and a cross-reference view for identifying all locations where a specific instruction is used. You also have new tools, such as the address picker which allows you to view your entire PLC memory and the corresponding MODBUS addresses, assign nicknames, assign retentive or initial values, and add an address comment for each.

The Web based help file and software manual, both incorporated into the CLICK PLC programming software, are like having your own award-winning technical support staff right in your PC. And since the PLC retains all documentation within the downloaded project in the CPU, field troubleshooting is greatly simplified. The CPU has two built-in RS232 (MODBUS RTU or ASCII communications) ports for programming, monitoring and communications to most any MODBUS-enabled device. The CPU also has both master and slave capabilities standard with communications speeds from 1,200 baud to 115,200 baud.

There are some hardware restrictions with this initial release. At the outset this is a discrete only controller. We offer various input/output combinations of AC/DC and relays, both integrated into the CPU as well as optional stackable I/O modules.

The addition of process monitoring and control will be available soon with the introduction of our analog I/O modules as well as a variety of CPUs with built-in analog control incorporated along with the discrete I/O.

If you need HMI for your application, the CLICK PLC and C-more Micro-Graphic panel were literally made for each other. You can use a single cable for communications and power between the two; plus, no additional power supply is required for the C-more Micro.

Available for the CLICK PLC is the ZIPLink wiring solution, offering the convenience of a five-second wiring solution from the I/O to a connector module. You can land your field wiring, eliminate additional terminal blocks and reduce the time it takes to build your panel (Figure 6).

You’ve heard the phrase, “Seeing is believing.” To get the true experience of the CLICK PLC, take it for a test drive. Go to our Web site www.clickplcs.com for an interactive product tour which provides details of the product from hardware to software, pricing and even a direct link to the web-based software help file. From this site, you can add parts to your cart on our web store and link directly to the software download page.

View products from AutomationDirect that relate to this article: CLICK PLCs

By Jeff Payne,

AutomationDirect Product Manager

PLC, I/O and PC-Controls Group

Originally Published: Dec. 1, 2009