Although many think of PLCs as primarily for real-time control, modern versions make it easy to implement extensive data connectivity and analytics.

While everyday consumers are familiar with getting things their way, this type of flexibility has often been less available within the industrial manufacturing arena. This is an issue for many end users when they need to deploy data-driven solutions to support efficient production of customized products.

In a Control Engineering March 2023 article titled Controllers, Interfaces Provide Advanced Edge Computing Capabilities, Damon Purvis at AutomationDirect identifies how modern PLC developments make it easy for automation designers and OEMs to meet their need for data access, and achieve close integration between PLCs or HMIs and enterprise systems.

Data ascending

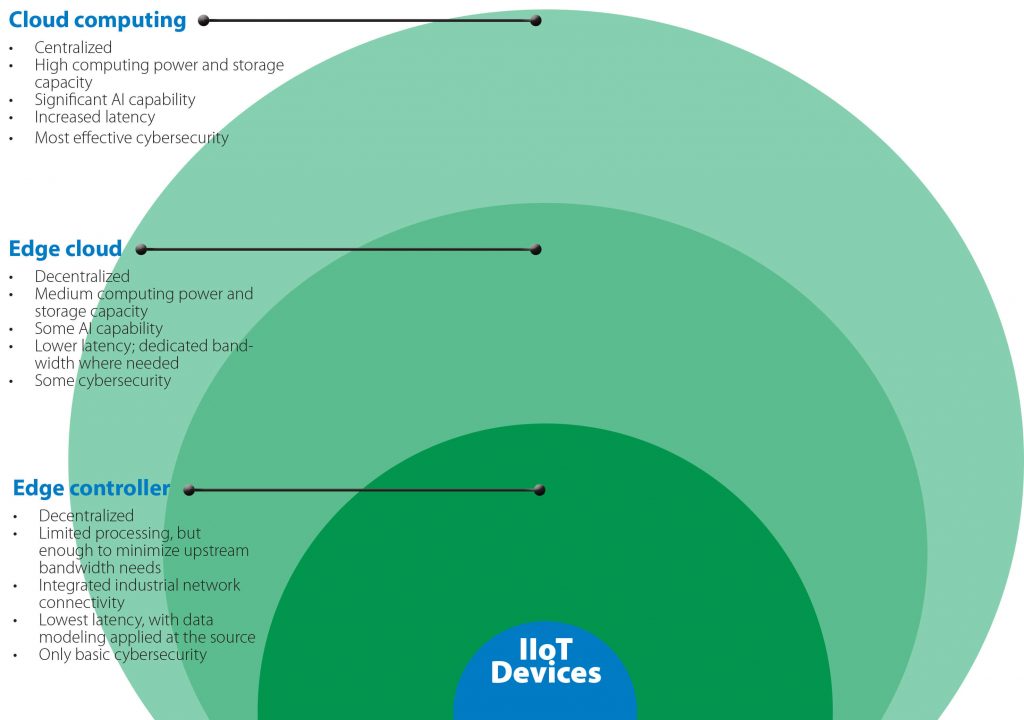

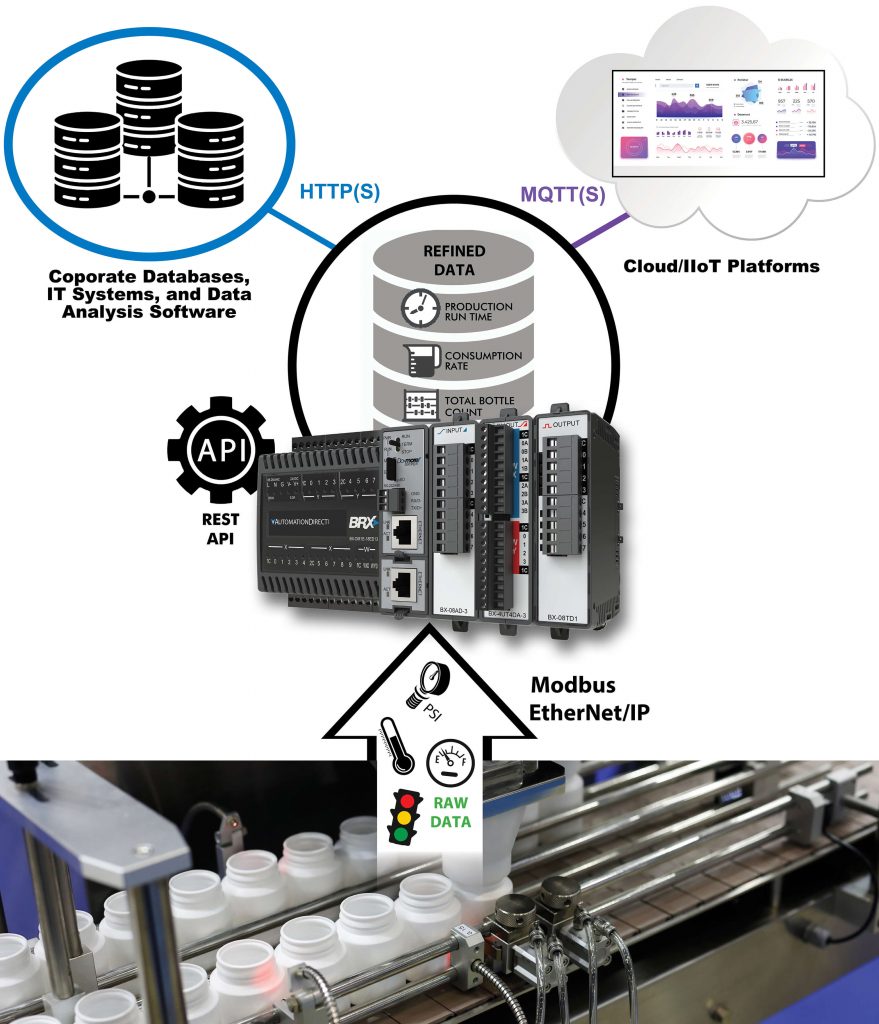

Various estimates make it clear that the amount of data created, captured, copied, and consumed globally continues to escalate. Industrial internet of things (IIoT) technologies are being implemented throughout manufacturing industries to facilitate the transport and processing of valuable operational technology (OT) data, often in conjunction with information technology (IT) systems. Plant floor data is digital gold—but only if it can be accessed, contextualized, and transported securely.

Traditionally, PLCs and HMIs provided basic control and monitoring functionality, and SCADA systems enabled a degree of data accessibility. Improving OT devices, and the convergence of OT and IT, are making streamlined data access with PLCs and HMIs more practical, even for small- to mid-sized machines and process units.

Realistic data access

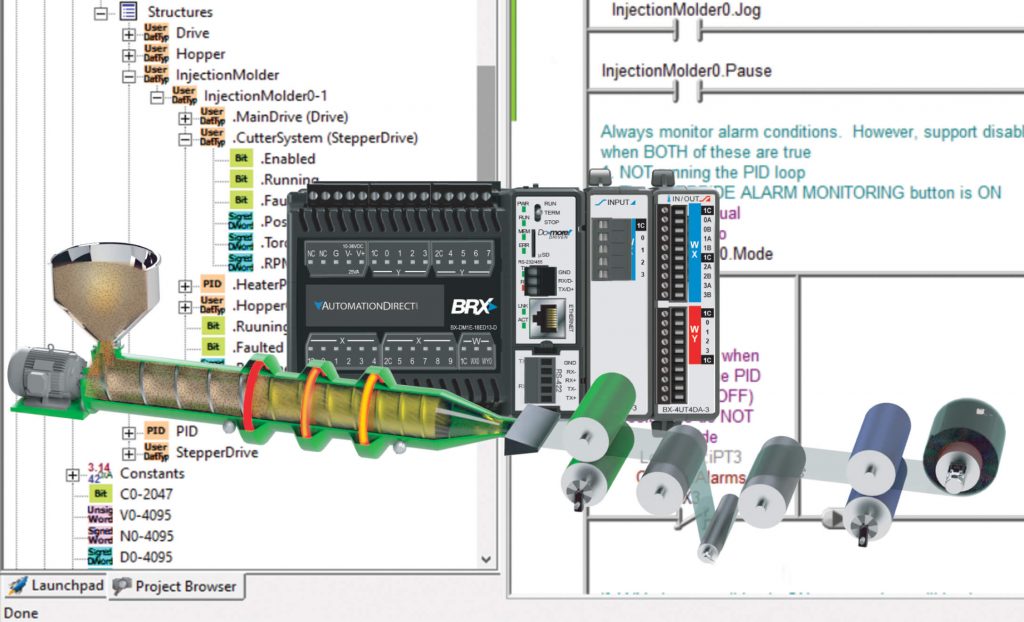

Instead of developing custom platforms, or over-specifying edge controllers, OEMs and designers can now use modern PLCs as a scalable approach to support extensive networking, data contextualization, and low-latency data processing tasks.

For example, the AutomationDirect BRX PLC can:

- Monitor and control field devices using I/O and a variety of industrial fieldbuses

- Communicate to higher level systems using MQTT, secure REST API, and other methods

- Pre-process raw data to minimize the amount of upstream traffic associated with data intake and transformation

PLCs go beyond the basics

Industrial automation designers prefer standardized solutions, but they may be concerned about investing in an approach that might limit innovation as their product range and needs expand. Fortunately, a solution is at hand:

Modern PLCs and HMIs can address these issues because they help ensure reliable overall functionality with the capability to execute essential tasks now while performing more advanced computing in the future. Users can implement this type of edge technology today to deliver right-sized and cost-effective automation using familiar platforms while leaving the door open to create more advanced applications, such as edge computing functions, as needed.

Visit the AutomationDirect website to discover a wide range of PLCs, HMIs, networking hardware, IIoT cloud platforms, and more to provide the real-time control capabilities you need now, with the flexibility of handling future needs, whether anticipated or unexpected.