A trapped key system uses a series of mechanical locks and keys to control the access of gates or doors to active equipment or machines, ensuring safe access to those machines. Systems are set up in a predefined sequence, or key transfer plan, preventing accidental access to equipment. A mechanical solution providessafety which cannot be defeated.

Here we review some of the features and answer several frequently asked questions about Trapped Key Systems.

Q: What is a Key Transfer Plan and why would I need one before I purchase a Trapped Key solution?

A: A Key Transfer Plan is a picture-based “map” of how your safety application is laid out. The more detailed the better, but it should include drawings of the doors on a machine or plant floor. Connecting these points with lines to associate a sequence of locking and unlocking help provide an overview of desired operation. For example: requiring one key at the panel to use in an exchange box to release three other keys for use in different doors is a typical use.

Q: How does a trapped key solution work with my current safety controls and PLC?

A: The Dold Trapped Key solution requires only one wiring point. The standard SX or solenoid locking ZRH base houses force guided contacts and feedback circuits similar to a standard safety switch; this is your electrical connection with your machine. Other components are mechanically related, so essentially you have a wireless safety system. This is ideal for applications where the control and the guarded gate are farther away which would be expensive to hardwire. And, if you have several machines of varying origin you can tie guarded access together on all of them.

Q: A trapped key solution seems higher priced than purchasing several standard door locks; why?

A: Because of the mechanical nature of these locking key systems they are very robust and designed for extreme conditions. Made of solid stainless steel, the mechanical components can tolerate temperatures from -75C to 140C while withstanding outdoor weather and aggressive food and beverage cleaning procedures. The components are engineered to mechanically handle impact, gate and human pull forces and the keys are robust as well as ergonomically friendly.

Q: What other benefits does a trapped key solution provide?

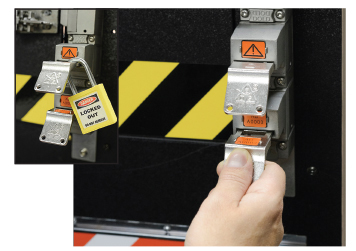

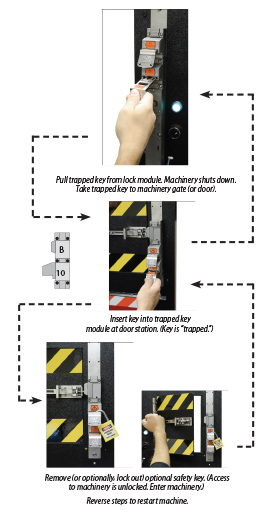

A: Having a mechanical solution provides you with a safety sequence that cannot be defeated. Once your key transfer plan is set, you have mapped out defined steps to gain access to a gate or door. For example, an operator must stop the machine to release a key, but then he must insert that key into a gate that releases a safety key which must be taken with him, that can then be used to release a door. The operator cannot lock that door or restart the machine until his safety key is reinserted. Since that safety key is unique, there is no way for the operator to bypass this step to restart the machine.

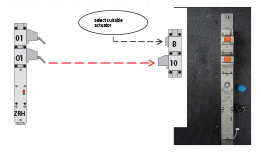

Q: What is the maximum number of doors/gates I can protect?

A: Our sets are sold in kits for 1-5 doors where all the keys and their corresponding 01 and 10 modules are identical within a set, but unique to any other set. However, when adding expansion lock sets from our accessories, the number of doors/gates you can protect is limitless.

Q: My safety application may change over time; how flexible is this system to alter?

A: The Dold Trapped key solution is a modular design so changes are simple. Each component links together with a universal rotary lock on the top and bottom. You can build these in any order suitable for your application and disassemble to add or subtract from it as well. For example, a lock-out or safety key can be purchased as an accessory and inserted anywhere in the system.

Q: What other accessories are available?

A: Our pre-drilled mounting plates make installation easy and come with all the T20 and T20 tamper proof screws needed to mount your Trapped Key solutions. Made of solid stainless steel, available in lengths for between two and nine-component module stacks, these plates save time and money by avoiding custom installation fabrication.

TYPICAL FLOW OF A KEY TRANSFER PLAN

Q: How do I specify the correct system for my machine?

A: There are several resources available on AutomationDirect’s website, including a five-step selector guide, video, and more. These tools can assist the designer in specifying and building the system as well as choosing needed accessories. Ordering a larger gate set than needed for the number of gates in a system compromises the safety integrity of that system and spare keys are not available. Assessment of the safety need in the beginning is crucial. If your system is excessively complicated you may want to seek professional advice from a safety expert. Please see: www.automationdirect.com/trapped-keys

By Andrew Waugh, Sensors & Safety Product Manager, AutomationDirect

Originally Posted: Sept. 10, 2014