It’s not just the low price, but the incredible built-in features that make our Productivity2000 a must-have controller. As the newest programmable logic controller from AutomationDirect, the Productivity2000 (P2000), is built around a compact modular form factor that allows both fit and functionality in a small space. But, what is Productivity2000?

In this introduction we will discuss key features and answer some frequently asked questions about this mighty-mite control system. From the built-in capabilities of the CPU, the documentation at your fingertips with the QR codes, to the ultra-clear OLED displays that give you more than just module status, the features are numerous.

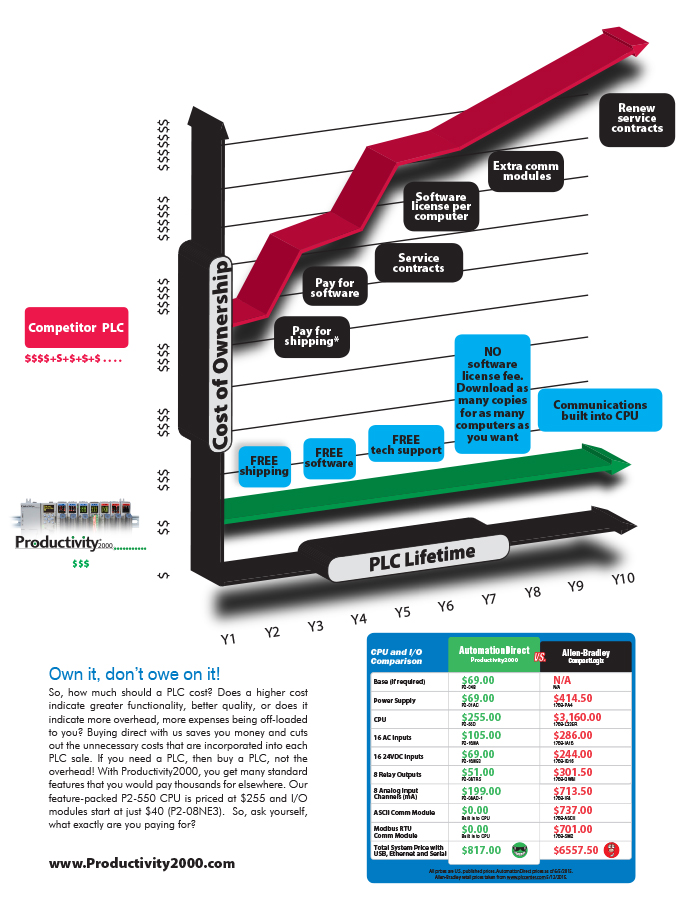

Let’s Talk Price

Let’s face it, when you’re working within a budget you have to make difficult decisions. Sacrificing quality is not an option, and your time is more valuable than most any line item on your BOM. With AutomationDirect products, our customers typically pay a fraction of the cost when compared to our major competitors. And with Productivity2000, you can rest assured that you have installed a high quality control system to increase productivity, saving time and money.

When comparing basic hardware the savings are obvious; however, the real savings are in the recurring costs you save when compared to those levied by most of the major suppliers in our market. Some of these include:

- Software costs

- License fees per PC

- Annual service contract

- Access to online resources (forums, firmware, downloads, etc.)

When shopping for a control solution, you need hardware and software; you don’t need overhead and recurring costs. Choosing the Productivity2000 is choosing the lowest total cost of ownership:

- Low initial hardware cost

- Free shipping

- Free programming software

- Free software / firmware upgrades

- Free technical support

And as always, we provide up front pricing with no strings attached. Our feature-packed P2-550 CPU is priced at $255 and I/O modules start at just $40 (P2-08NE3).

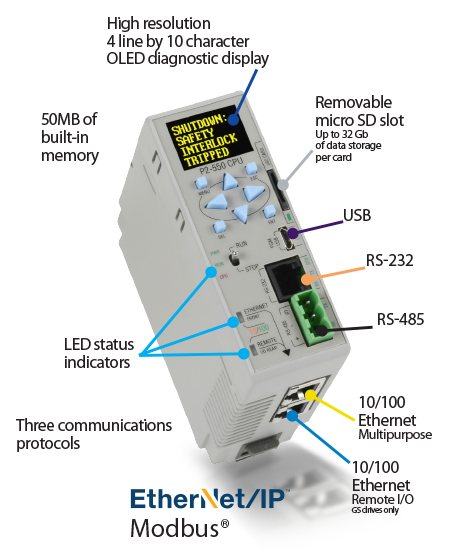

What about Communications?

What about Communications?

One of the staples in the Productivity Series is the CPU’s built-in communications capabilities. Ethernet, serial, and USB ports, along with the protocols needed for connectivity, are available as standard features on this CPU. No need to pay extra for Ethernet and USB ports; no need to add modules to your base which consume valuable I/O slots. And, there is no need to pay extra for the industry’s leading Ethernet protocol, EtherNet/IP. This powerful controller definitely gives you “More bang for the buck.”

The CPU module includes:

- (2) Ethernet ports that support EtherNet/IP, Modbus TCP, GSDrives (auto-discover), Email, programming and troubleshooting

- (2) Serial ports, (1) RS-232 and (1) RS-485, that support Modbus RTU, ASCII and even ‘Custom Protocols’ you define within ladder logic

- (1) Plug-n-Play USB programming and monitoring port

In addition to the vast communications capabilities, there is a microSD card slot for data logging and project transfer, and a high clarity Organic Light Emitting Diode (OLED) display for diagnostics and simple message display.

What about Programming?

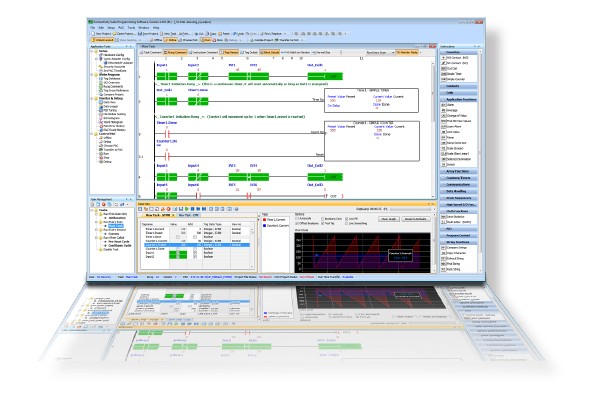

The ProductivitySuite programming software is designed for flexibility and customization. Organize the layout in a way that best satisfies your programming style and preferences.

Easily auto-discover your system I/O and connected GS Drives in the system’s hardware configuration.

Use the tag database import/export to manage your tags names, or for use with peripheral devices such as OIP, HMI and SCADA packages.

Data View gives you three separate ways to view your process or machine data.

- The simple data view is a table view where you add the tags of your choice, view the current data, edit or force the data and monitor the Modbus address.

- Graph view lets you drag any tag from the table view and begin plotting those data points on a line graph.

- I/O view offers a unique graphical look at your current physical I/O modules and their data.

Time for Q & A

Does the Productivity2000 support high-speed I/O modules?

Yes, we have both a high speed input (P2-HSI), supporting 2 channels up to 1MHz/each, and a high speed output (P2-HSO) also with 2 channels up to 1MHz/each. Both modules sell for $195 and both have additional general purpose I/O.

Can I collect data with the P2-550?

Yes. The P2-550 CPU has a microSD card slot built in, so recording data from process values is as easy as adding a tag to a list and selecting the frequency at which you would like it to be recorded, or define the event that you would like to trigger the process.

What are the benefits of the OLED displays?

The display on the CPU will show critical and non-critical fault messages as well as custom messages configured in the ladder using the LCD instruction.

The analog module displays provide process data and module status at your fingertips – a pricey feature from our competitors. We give you 4 or 8 channels of raw analog values (i.e. 0-10V or 4-20mA), converted digital values (i.e. 0-65535) and even actual temperature in deg F or deg C.

How is TAG NAME programming different from a “typical” PLC?

There are two basic types of memory addressing in PLCs today: Fixed addressed memory and Tag name database memory. First, I woing.uld point out that the majority of all controllers designed in the past 15 years are tag name based controllers. Since PLCs are designed to be installed and operate for decades without being replaced, sometimes progress moves slowly. Let’s look at how both types function and consider some benefits of Tag based programming.

-

- Fixed address controllers have a set amount of memory allocated for each data type, i.e., 16,000 In, 16,000 Out, 4095 integers, 4095 floats, 512 timers, 256 counters, etc. The down side is they’re not adjustable and if you run out of a particular data type, you have no additional options.

- Tag based addressing is more dynamic. You assign data types as you create your tag names. You have a maximum amount of memory allocated for that data and it is free form, meaning that you can create as many or as few different data types as you need to suit your application.

-

- In fixed address controllers you have entities represented by letters and numbers. i.e. X1 for an input, O0:4/13 for an output, C200 for an internal control bit or N7:32 for a 16-bit integer entity. These are easy enough to work with, once you learn them, but they mean absolutely nothing with regards to the real world devices they are connected to and controlling.

- In Tag based addressing you name the memory location, i.e., SYSTEM_START for an Input, EXHAST_FAN_ON for an output, PURGE_TIMER for a timer, QA_REJECT for a counter, AUTO_MODE for a control bit and DWELL_TMR.PRE for an integer.Descriptive naming

The key benefit is that the programmer is forced into following preferred programming practices and adequately documenting his/her project. With the Productivity Series controllers, the tag name database is always downloaded to the CPU with the project, so it is no longer necessary to have an up-to-date copy of the project file on each computer. The user could connect to the PLC with a new laptop and have access to 100% of the documentation – a tremendous benefit when troubleshooting a system.

Additionally, with each project we save a .csv file of the tag database in the project folder with the same name as the project. This allows the user to easily import this file into C-more HMI software, Point of View SCADA, KepOPC software, DataWorx Database software, etc. If you prefer, you can also manually edit the tag database in Excel.

What aspects of the EtherNet/IP protocol are supported by Productivity2000?

The EtherNet/IP protocol has four key areas: I/O Messaging, Explicit Messaging, Tag Based (Symbolic Addr) and PCCC. The Productivity2000 currently supports the following:

- I/O Messaging (Class 1 implicit)

- Class 3 Explicit Messaging (Connected)

- Unconnected Explicit Messaging

- Both Client and Adapter configurations are supported (separately or at the same time)

What information do I receive when I scan the QR codes?

Most seasoned engineers or technicians can relate to working on a job site and not having the documentation that you need readily available. This is very frustrating and time consuming when working on a system. With the new QR codes affixed to all Productivity2000 I/O modules, you have instant online access to module spec data and wiring diagrams.

Are there plans for remote expansion for Productivity2000?

Yes. We will be offering multiple expansion options for the Productivity2000 in the future.

Are the AutomationDirect GS drives auto-discovered in Productivity2000, like they are in the Productivity3000?

Yes. This is a feature that has many benefits.

- Auto-discovery saves you time when connecting the components together.

- Configuring VFD parameters from the PLC software saves you time during initial setup. However, you also get the added benefit of storing those parameters in the PLC project file. If you have to replace a drive in the field, the current configuration is retained in the project, and can be transferred to the new drive, saving you even more valuable time when a machine is down.

- GSR (read) and GSW (write) instructions are designed specifically for controlling the GS Drives, making programming and startup a snap.

- For additional information on using GS Drives with the Productivity Series controllers, view our video series on the video player below:

Is there an easy way to get started on evaluating the Productivity2000?

Yes. The ProductivitySuite programming software is and has always been a free download from our Web site. We encourage any new user to download the program and “click around” to see if you like the look and feel; it has a very detailed Help file which addresses questions on how the system works.

Download ProductivitySuite here.

Once you’ve made a decision to purchase and evaluate the Productivity2000 hardware, we make getting started very simple with our convenient starter kit (P2-START). This comes complete with:

- P2-04B, 4 slot base

- P2-01AC, 110 VAC power supply

- P2-550, CPU

- FP2-08TRS, relay output module

- P2-08SIM, input simulator

- 3 different wiring options:

- screw terminal block,

- spring terminal block, &

- ZIPLink pre-wired cable and feedthrough connector module

- USB programming cable

- Programming software on CD

- User’s manual

- 16 G microSD memory card

- Mini torque screw driver

- 3-wire power cable

- 30-day FREE Training certificate

Everything you need to get started is here!

Originally Published: Sept. 3, 2015