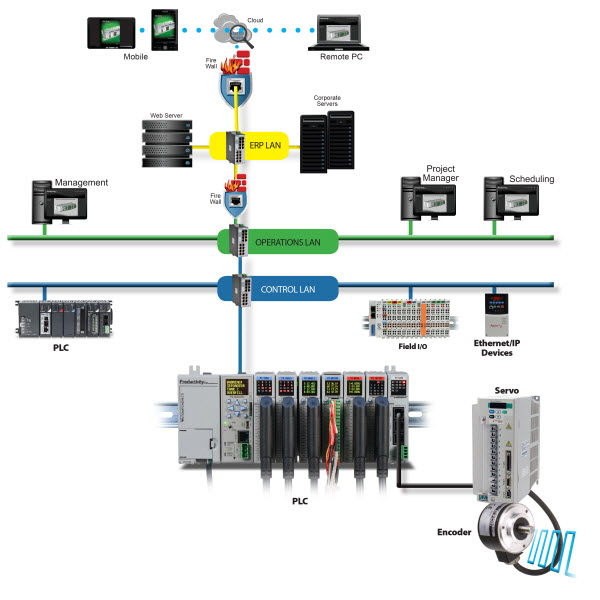

The IIoT starts with edge devices. Connecting these sensors, actuators, motors, drives and other smart devices to PLCs and other advanced controllers is the first step. The connection continues through the HMI to provide data sharing to both local and remote users through corporate intranets and the Internet. Connecting edge devices and distributing the data to the users of the data—the decision makers—is an important goal of IIoT, and is facilitated by industrial controllers and HMIs.

Connecting the Edge

Data originates at the industrial plant, factory or facility and comes in many different forms, formats and protocols. Edge devices can provide a single data point for a simple function like a presence switch, or many items of information for a complex component such as a motor drive. PLCs and advanced controllers such as AutomationDirect’s Do-more! BRX, Productivity2000 and Productivity3000 have the features, storage capacity and connectivity needed to tie the edge devices to the IIoT, either directly or through an HMI.

Not only can these advanced controllers interface to a wide variety of edge device signal types, they have the processing power to make logical decisions, scale the data, perform calculations, store the data or push it to upper level databases. For example, the Productivity series advanced controllers have the capability to handle signal types from a large number of edge devices including:

- Discrete Sensors

- Analog sensors such as current, voltage and other transducers

- Temperature, pressure, flow and other transmitters

- Analyzers measuring chemical composition of process flows

- Motor drives

- Control valves

Whether a single discrete signal, a discrete signal with diagnostic information included, an analog current or voltage signal, or a smart device transmitting information via Ethernet—advanced controllers are the initial gathering point for this important information.

The controller helps format the data and get it to the decision makers quicker. In addition to scaling and organizing the information in data tables, some controllers, like the Do-more! BRX PLC, can email the data file directly to the appropriate personnel or can write to local storage devices such as microSD cards. These cards can then be removed and used to transfer data to other applications. As more advanced controllers are added and data collection requirements expand, the data collection and logging capabilities of a PC-based HMI software package can be used to handle this increased information.

Connecting and Distributing Controller and HMI Info

AutomationDirect’s advanced controllers make it easy to connect to HMIs, and from there to the IIoT. With on board USB, serial and Ethernet ports (available on most models)—there’s no need to add hardware to the controller because IIoT connectivity is built-in. With the EtherNet/IP protocol leading the way and Modbus TCP firmly in second place, connectivity in the North America market is well taken care of in these controllers.

This connectivity makes it easy to share data among controllers and the HMI. The tag name database in the Productivity controllers is where the data tags are created and then shared with the HMI. Both the AutomationDirect C-more touch panel programming software and many PC-based HMI software packages include a tag name import function so tags don’t need to be re-created, just imported from the Productivity controllers. Once imported, the tag is selected as needed to create objects, trends, alarms and graphics in the HMI.

Using the Web server capabilities built in to embedded HMIs, like the C-more, is a good way to distribute the collected data, but many HMI/SCADA software packages can also be used to distribute data through a local thin client or a web-based remote thin client.

At the local network level, connection to the runtime PC using a secure viewer thin client is common. As the need to view the HMI more remotely increases, Web thin client functionality and an Internet connection from the PC hosting the HMI software allows interaction via any device capable of hosting a web browser such as a remote PC, a smartphone or a tablet.

IIoT functionality and capability is being built into advanced industrial controllers and HMIs, allowing users to collect, present and use data to make decisions. For more information, please see the IIoT’s Power Found in Controllers, HMIs article in the April 2016 issue of Plant Engineering magazine, authored by Jeff Payne, the Automation Controls Group Product Manager at AutomationDirect.