The 2012 year has brought many new enhancements for the Productivity Series control platform; you will notice subtle improvements to the software as well as major module additions such as the High-Speed Counter and Pulse Output modules. In this article we will review these enhancements to offer a better understanding of current product updates.

The software has received several advances in our most recent releases. The enhancements were based on feedback and suggestions we received from our customers and from those using the software utility on a regular basis. Our goal is to continue to improve the usability of the product until we are satisfied you have the best programming tool in the industry.

Bit-of-Word Data Types Support

The addition of Bit-of-Word support complements the use of arrays for manipulating individual bits of a word. You can now target individual bits of an Integer tag in any instruction that accepts a Boolean tag.

Data View Trend Graph

The new trend graph addition to the Data View gives you the ability to quickly chart Boolean tags or integer values you are currently monitoring in the Data View window.

New Toolbars

New toolbars were added for the Ladder view, Data View and Task Management panes to optimize space and improve the ease of use. Look for more of these toolbars throughout the software as well as additional functions to be added to these new toolbars.

Tabular PID Tuning Window

You can now monitor and tune up to five separate PID loops in the PID tuning window, giving you the ability to more easily tune and adjust your entire process.

Search & Replace Enhancements

The latest improvements to the Search and Replace feature include separate Tag, Comment and Instruction searches and the capacity to Find and Replace partial tag names. This can be especially beneficial when your application calls for extensive duplication. For example: Create one PID loop called “Oven1”. Then create and assign all associated tags (Oven1_SP, Oven1_PV, Oven1_P, Oven1_I, Oven1_D, etc.). Now you simply Copy/Paste the first instruction in your ladder code and Find/Replace “Oven1” with “Oven2”, and your second PID is complete (repeat for as many instructions as you need).

Add Multiple tags to Data View

With two mouse clicks (Right Click > Monitor in Data View) you can now add all tags from a single instruction, an entire rung or a group of rungs to a new Data View tab. This eliminates a tremendous amount of time when troubleshooting specific areas of code.

Enhanced Print Options

Customization was the focus when working with the latest print features. We discovered that users are looking for different ways to print their ladder code, so we added the ability to rung wrap and show even the longest and most complex rungs on a single page, select the font size, default font type and custom fonts for each comment type, wiring labels, System IDs, etc.

Revamped Firmware Upgrade Tool

This now allows you to quickly compare the Firmware versions, view firmware files offline and filter on the module type(s).

View Tag Comments in the Ladder

The new toolbars make it easier to add some features. There are many viewing options in the ladder code offering more customization and the ability to see varying levels of detail. You have toolbar icons for enabling and disabling Task comments, Run comments, Instruction comments, Tag names, Tag details and Block details. Enabling the Tag details will show the comment field associated with each tag from the Tag database.

Task Management Sync

The Task management window is where you organize all program tasks. These tasks can be many and in various folders. The new “Sync with Editor” option ensures the task you select in the Task management pane is the task you are currently viewing in the Ladder editor.

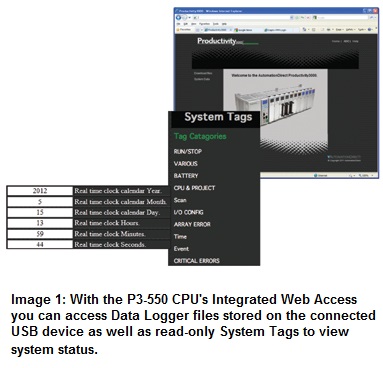

Beyond this list of software enhancements are a couple of major additions to the product. First is the built-in Web Access; with this you gain access to data log files stored on the removable USB drive, system tags and error and event history. This is an excellent tool when paired with the built-in data logging feature of the P3-550 CPU. You can now access process data from anywhere (with the proper provisions and security considerations). Simply configure your CPU’s data logger to store files to the removable USB device port and enable the Web server from your CPU’s hardware configuration page. From here it merely requires you typing the IP address of the CPU into any browser and your data is at your fingertips. See Image 1.

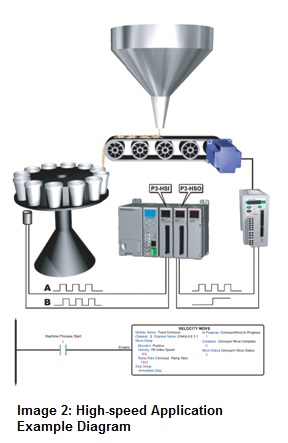

Our latest hardware additions include the High-speed counter input (P3-HSI) and Pulse output (P3-HSO) modules. These new 2-channel modules add high-speed and motion control applications capability to the Productivity3000 controller, and they’re easy to use! Add up to 22 of these modules in any combination – that gives you up to 44 axes of motion or high-speed counting capability in a single system.

Drop-in Hardware Configuration

Install a high-speed module into the system hardware configuration and define each channel’s behavior, status bits, limits and scaling, all without the need for an external configuration utility or software.

Simple Instructions

Our standard instructions were designed to make your everyday motion applications simpler. The Find Home, Set Position, Simple Move and Velocity Move instructions (to name a few) were created to get you operating more quickly. Capabilities such as Registration, Jerk Control and Channel Scaling were included to give you the flexibility to accomplish those jobs.

Application Example

In the diagram, high-speed outputs synchronize the speed of the servo drive controlling the fill conveyor. The conveyor is synchronized with the rotational speed of the turntable based on the signal(s) from the table encoder feedback via the high-speed input module.

Summary

All these features were designed to help get your project up and running in minutes, not hours or days. Look for additional enhancements to these modules in the future.

We continually strive to improve our products and value your opinion. Please download the latest software revision and take a test drive. If you have comments or suggestion for improving the product further, please visit our site below or contact our Technical Support staff at 1-800-633-0405.

For additional information on these features and more, check out the Productivity Series here.

By Jeff Payne

Product Manager; PAC/Programmable Relays

AutomationDirect

Originally Posted: June 1, 2012