If you visited the Baldauf family farm in Saginaw, Michigan years ago, you would have seen people busy tending to various crops and animals. Today you will see more than 350 employees assembling, fabricating, powder coating, welding, packaging, and shipping the electrical enclosures manufactured at the 331,000 sq. ft. Saginaw Control & Engineering (SCE) facility located at the old farm site.

The electrical enclosure company has been headquartered here since 1963, when Harold Baldauf founded it in a garage on the property. A few years prior, Harold had returned to the farm after serving in the United States Navy and began working at a local electrical distributor. He soon started doing electric work on his own, then founded SCE to wire electrical enclosures and eventually, fabricating enclosures.

“My father began the business with a focus on quality, value, service, and technology,” said David Baldauf, Chief Financial Officer and Treasurer of SCE. “We take great pride in that beginning and continue to offer those key benefits to customers today. We use state-of-the art fabricating technology, including the latest laser technology, to provide products that are protected with the highest quality powder finish available on the market.”

Today, SCE manufactures standard and custom designed electrical enclosures that house sensitive electrical and electronic equipment. Its standard stock includes free-standing, floor mounted, wall-mount, modular, operator system, pushbutton, and junction enclosures. The company custom manufactures carbon steel, galvanized steel, and stainless-steel enclosures to meet customers’ specific environment and application needs and supplies a wide variety of accessories. These products include compact LED strip lights that provide interior lighting for smaller enclosures and a thermal management line that includes carbon and stainless-steel air conditioners and heat exchangers.

Investing in Technology and Quality from the Start

SCE’s enclosures protect electrical and electronic equipment that powers machinery in the automotive, food and beverage, oil and gas, power generation, waste and waste-water treatment, technology, automation, pharmaceutical, and material handling industries. Customers value the state-of-the-art technology that the company uses to create its products. In fact, SCE has incorporated cutting-edge equipment and technology since its beginning, Baldauf notes.

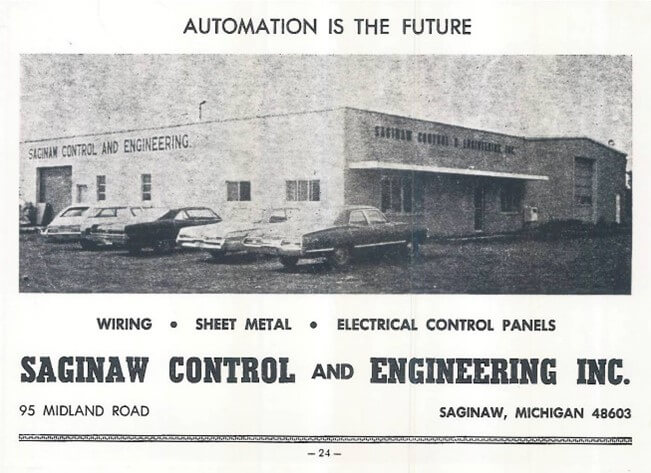

“In 1965, the company ran an ad in the local high school athletic brochure with a photo of the building and the heading ‘Automation Is the Future’,” he said. “We have stayed true to that beginning philosophy. We continue to invest in the latest equipment and automation technology to remain cutting edge and to keep manufacturing top quality products.”

He notes that SCE also has long been known for its commitment to quality and continuous improvement which it incorporates into its equipment, processes, and products.

“Quality is baked into everything we do,” Baldauf continued. “We collect real-time data so we can prevent issues from occurring instead of reacting to them. We want to be the leading manufacturer of standard stock and custom designed enclosures. We also want to provide real opportunities and solutions to each of our customers, grow our company, and deliver unparalleled quality, value, and customer service. To do all of that, we verify, monitor, and benchmark our products and services to meet agreed requirements and continuously improve our business, products, and services. It’s how we were founded.”

Expanding Through the Years

After its initial founding in the farm’s garage, SCE expanded its product line to increase its customer base. In 1983, it shifted its focus to just fabricating enclosures versus wiring them. In 1993, it opened its first distribution center and now has five centers located in Nevada, Ohio, Oklahoma, Tennessee, and Wisconsin. Combined, they house more than 215,000 sq. ft. of inventory and 2,500 items. About 70 people work at the centers and ship products to customers throughout the U.S., Mexico, Canada, and several other countries.

From 1996 to 2015, the company tripled the manufacturing capacity in its farm-located manufacturing facility by taking advantage of technology and automation advances. In 2020, an additional 144,000 sq. ft. manufacturing facility (about 5 miles from the original plant) was opened to supplement its capacity.

Serving as an Essential Supplier

SCE employees are dedicated to the company and its success. When the company was designated as an essential supplier when the COVID-19 pandemic took hold in early 2020, employees worked quickly to get enclosures shipped to Iowa to be used in five air treatment machines to make sure healthcare workers were breathing in clean air.

“We had five sets in stock and quickly started production of another 15 sets to help protect those frontline workers,” Baldauf said. “That made for a total of 45 additional enclosures we produced very quickly. All of us at the SCE family banded together to make that happen. We are glad to be able to help fight the virus by providing products to help people during this especially difficult time.”

Positioned to Grow

Baldauf notes that the loyalty and commitment of SCE’s employees and its manufacturing capabilities are key elements that will enable it to have continual growth and serve its customers for many years to come. The sales department prides itself on providing excellent customer service, fast and accurate quotations and assisting customers with any issues they might have.

“We project about eight percent growth per year and know that our employees are what make this possible,” he said. “I have the privilege of working with all of our team members, including my son and my brother-in-law and will continue to expand on my father’s dream of providing high quality enclosures to meet customers’ exact needs. That’s a privilege I take to heart. I love coming to work here and seeing the company continue to succeed.”

Harold’s grandson is Scott Baldauf and is the Vice President of Sales and Marketing. After graduating from college, he worked very hard learning the company business from the ground up and has earned the trust of his family to continue on the tradition of providing quality-built products, at affordable prices. Cole Van Strydonk, Vice President of Manufacturing joined the company shortly after college as well and married one of Harold’s granddaughters. Scott and Cole continue to keep Harold’s vision in mind every day. They are involved in the decision making on new facilities, new equipment purchases, new products, and standard operating procedures that help streamline the manufacturing processes.