Servo systems are a leading way to implement high-performance motion control, and the latest servo drives offer functional, programming, and diagnostics capabilities to help users quickly create and commission solutions.

Chip McDaniel, technical marketer at AutomationDirect, wrote an article posted July 2021 on Control Design titled Servo Systems Lead the Way to Implement High-Performance Motion Control. Here’s a summary, click on the link above for the full text.

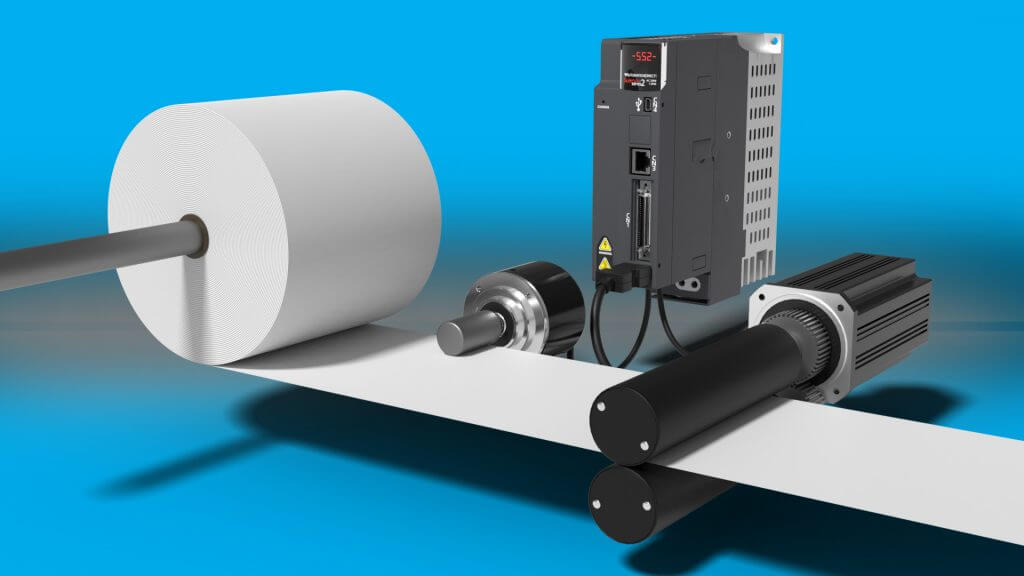

Servo motor systems are recognized as the high-performance motion solution for providing precise, responsive, and powerful control in applications such as robotics, machine control, and material handling. They are also known as a relatively expensive and complex option. That is changing as newer drives incorporate built-in features which make them easier to use, applicable for even more applications, and more economical.

Servo Basics

Servos are DC motors able to provide high torque, and they incorporate an encoder so the servo drive/motor system can operate in an accurate closed-loop manner. The drive translates command signals to operate the motor—sometimes following elaborate position, speed, and acceleration profiles. Maintaining product feed rates and registration accuracy are common applications.

On-Board Control

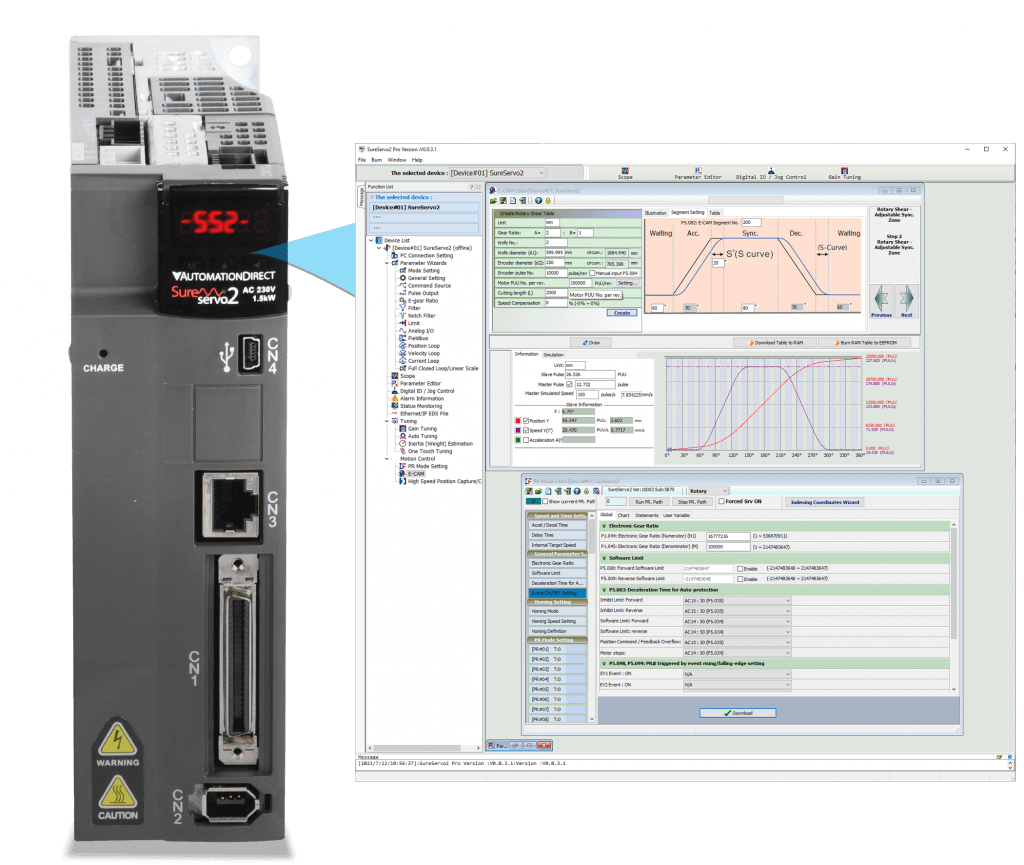

Many servo drives are commanded by PLCs or PCs. However, the newest generation of drives, like the AutomationDirect SureServo 2, incorporate wizard-like functionality and graphical user interfaces so users can take advantage of built-in control functionality like:

- Internal control logic

- Electronic gearing

- Electronic camming

- Rotary and flying shear control

- Registration

The ability to perform drag-and-drop configuration to implement these common functions simplifies and speeds designs.

Superior Startups

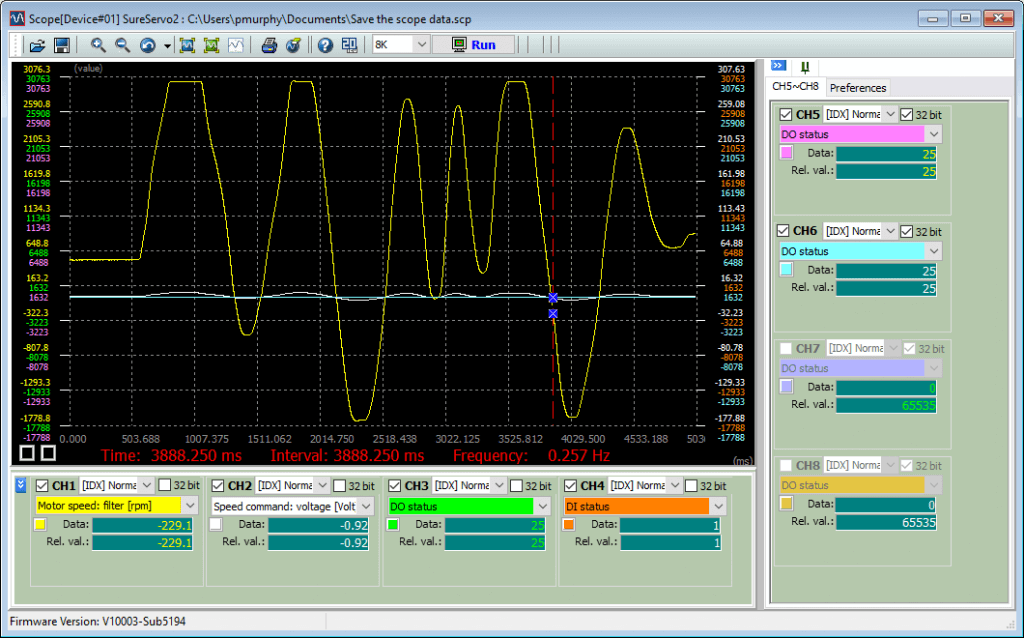

Typically, technicians may have needed test meters, an oscilloscope, and even a high-frame-rate video camera to startup, tune, and troubleshoot a servo drive and motor system. To ease this burden, the SureServo2 includes a built-in eight-channel oscilloscope and several automatic tuning options to meet most needs, including:

- Static auto tuning

- Running auto tuning

- Assisted tuning

- Manual tuning

These on-board tools minimize the effort for commissioning and maintaining servo systems.

Easier Servo Application

The AutomationDirect family of SureServo2 drives and associated motors are designed to help end users and OEMs solve their high-performance motion control needs, easily and economically.

By providing advanced processing and flexible configurability with many standard functions and setup/diagnostic tools such as auto tuning and oscilloscopes, modern servo systems give users of all types easier and less risky options for applying servo control in a wide variety of applications.