Industrial automation designers now have a variety of ways to incorporate an open programming approach for their projects.

Although industrial-grade digital technologies have been available for over five decades, much of that time the hardware and software has been specialized and even proprietary. This is at odds with a large segment of the commercial market, which has embraced open hardware and programming devices. However, open options for industrial automation platforms are surging, and the topic is explored in a Machine Design June 2024 article titled Open Programming Languages Flourish in the Industrial Space, by Tim Ensminger and Matthew Lappin of AutomationDirect.

Proprietary for a Purpose

While there are commercial reasons for making any product proprietary, a key factor in the case of industrial automation hardware/software is that these products must run reliably and safely in demanding environments for decades. General purpose solutions simply have not been up to the task. On the other hand, today’s end users, systems integrators (SIs), and original equipment manufacturers (OEMs) are pushing for more efficient development options so they can take advantage of interoperability and design portability.

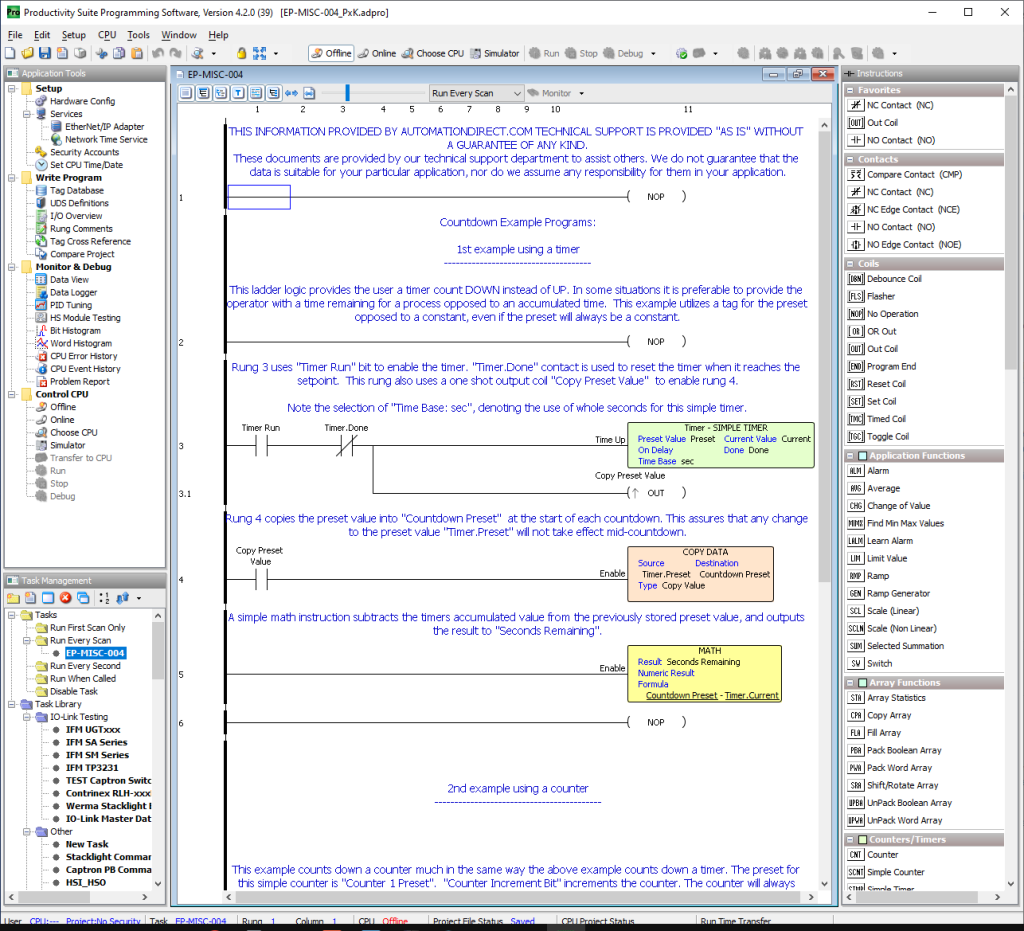

Early PLC development environments where vendor-specific, and they mimicked the look of electrical wiring diagrams. This prompted users to become locked-in with certain suppliers, and it caused them difficulties with switching to other alternatives. Traditional PLC programming is still useful for many automation purposes, but today’s developers are looking for ways to streamline design efforts and support more data-intensive applications.

PCs and Ethernet are commercial off-the-shelf (COTS) technologies, and both have been at the forefront of more open industrial implementations. Other developments supporting openness include:

- Standardized IEC 61131 languages, which helped align manufacturers to a degree (although they did not make it possible to port code from one vendor platform to another).

- Common integrated development environments, such as CODESYS, which does support portability among various runtime platforms.

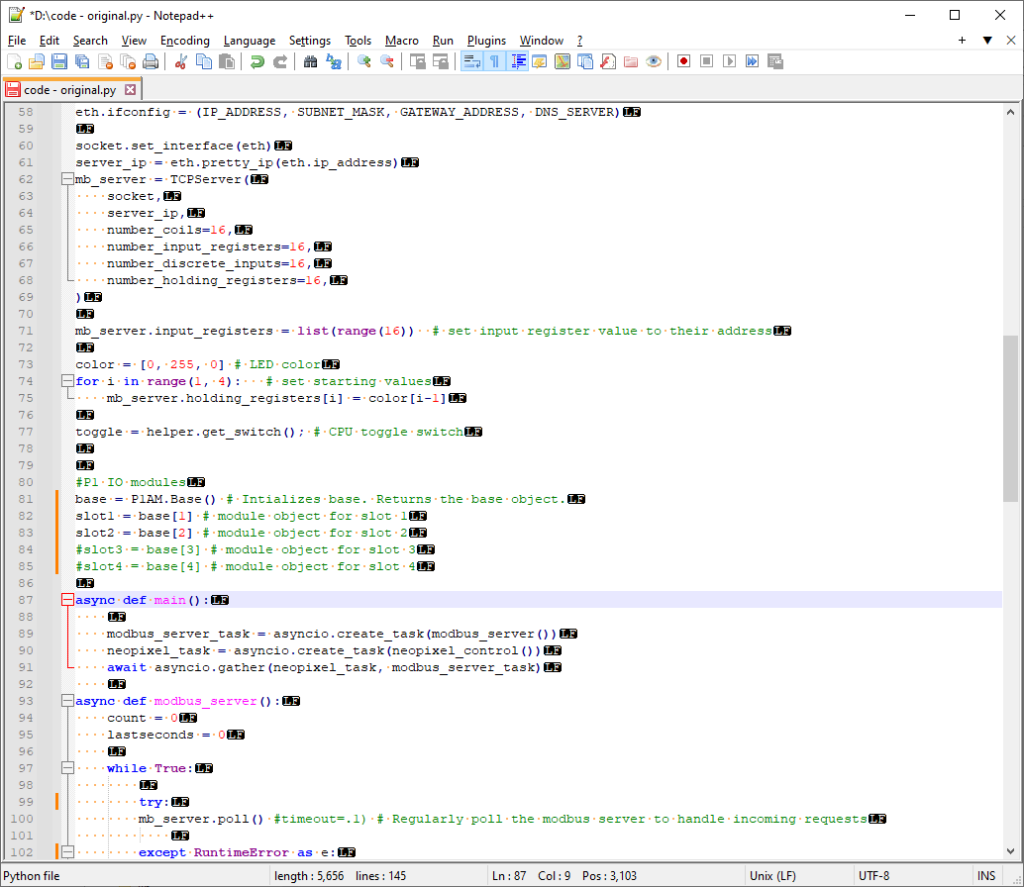

- Open microcontroller platforms (such as Arduino and Raspberry Pi), which can use modern IT-based programming languages, such as C++ and CircuitPython, and may even connect with industrial-grade wired I/O.

Modern text-based programming languages are better adapted for some types of computing—especially data handling and analysis—and they are also more familiar to many young developers entering the work force.

The Open Road

Traditional PLCs and automation products are not going away any time soon, but newer and more open options can help developers streamline their efforts.

Open languages often mean a reduction of software and licensing fees for end-users, and other efficiencies as designers scale and adapt their work. When developers have access to more communications protocols and standardized computing options, they have more freedom to create valuable solutions.

Recognizing this, AutomationDirect offers a full and evolving portfolio of traditional PLCs, CODESYS-capable PLCs, and Arduino-compatible open controllers, so end users, SIs, and OEMs can find what they need to build more open solutions.

Visit the AutomationDirect to discover the choices available to support your evolving automation requirements.