In materials handling and assembly there are many ways to move an item from one location to another. Conveyors are one way and are widely used, but they can only move objects in a fixed path, limiting their use in more precise manufacturing applications. When more accuracy is required than a conveyor can deliver, such as when the part orientation or alignment needs to be changed, a pick-and-place system is often used. The most common pick-and-place systems employ either pneumatics or electromechanics, with hybrid electro-pneumatic systems also an option in some applications. The question then becomes what system is the best for each application, taking into consideration multiple factors including cost, complexity, performance and maintenance.

Picking the Right Pick-and-Place

In regards to complexity and performance, one should consider the amount of movement(s) that must be performed, the required accuracy of the placement, the weight of the objects to be lifted, the shape of the parts, and the distance they must travel. In general, jobs with complicated movements requiring a high level of accuracy need more expensive electromechanical pick-and-place systems. If the application has a fixed travel path and doesn’t need repositioning or multiple positioning, a pneumatic pick-and-place system is often the best choice.

Hybrid systems use electrical components at the front end, and a pneumatic end effector to handle the part or object. These systems are more expensive than pneumatic solutions and less costly than electromechanical systems, and can be the best option for some applications as they combine the economy of pneumatics with the speed and accuracy of electromechanical systems.

When Pneumatic Pick-and-Place Systems are Better

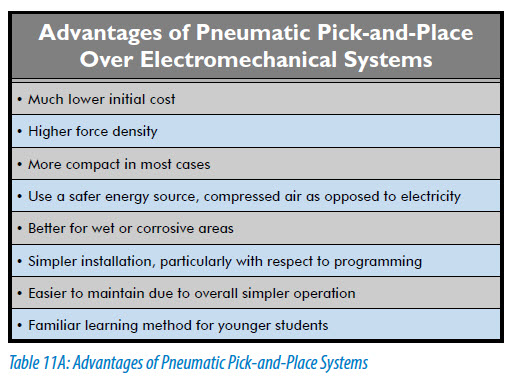

Although initial cost is often the driving force for using pneumatic pick-and-place systems instead of electromechanical solutions, it’s not the only reason, as seen in the Table below.

Pneumatic devices have a greater force density than many electromechanical solutions, which enables them to be a smaller and lighter, lowering space needs and energy costs. They can also be installed without complex components like controllers, as their operation is simpler with a single path of travel. In applications with contaminates, such as possible splashes, electromechanical systems pose more danger and are more likely to fail. Furthermore, electromechanical pick-and-place systems for these types of applications usually require specialized certifications and have a relatively small pool of vendors, thus making them quite expensive.

Pneumatic systems are not only safer in wet or corrosive environments, they can also withstand numerous cleanings. The pneumatic devices can be mounted close to the process while the associated electronics are housed in a cabinet well away from possible damage, simplifying installation and maintenance. Moreover, since controls for a pneumatic system are typically smaller than servo drives, internal space requirements in the control cabinet are reduced.

Build or Buy?

When the decision is made to implement a pneumatic system, the next choice is to buy an off-the-shelf system or to build one using cylinders, valves and end effectors. A preconfigured system will be in operation faster as it comes with all components pre-assembled and tested. Designing and building a custom system will take more time up front, will cost less in terms of purchased parts and will result in an optimal fit for the application.

Custom pneumatic pick-and-place systems can be built in a variety of configurations using standard components, which are assembled to produce different linear and rotary motion actions. A basic system can be built using primarily off-the-shelf components at a very reasonable cost. Nevertheless, designing a pick-and-place system requires a certain amount of engineering skill.

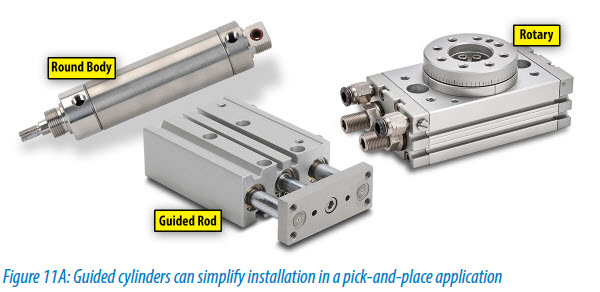

Pneumatic pick-and-place systems rely on cylinders for mechanical movement in either a linear or rotary direction. Round body cylinders are the least expensive option but they require mechanical guides that are usually custom machined for the particular application. As such, they may be the best choice for a company that can perform machining in-house. For those without in-house machining capabilities, guided-rod extruded-body cylinders are a good choice even though they can be up to five times as expensive as their round body counterparts.

Rotary actuators are used with cylinders to perform non-linear, twisting movements; they can flip, tilt or turn a part or an object. For example, a rotary actuator is used on one end of a vertical axis, with a gripper on the other end. This enables the actuator to move parts in an arc motion, instead of moving the object up and across in separate movements. It should be noted these actuators typically don’t rotate more than 270 degrees.

Readily available pneumatic cylinders are generally limited to about 2500 pounds of available thrust, but multiple cylinders can be combined into a very powerful pick-and-place system. These cylinders and other components come in a wide range of materials: nickel-plated brass, aluminum, steel and stainless steel. Designers should select the appropriate material depending on loads, environmental conditions and cost constraints.

Stroke Length Considerations

The stroke length determines how far the pneumatic device can move. Single-acting cylinders have limited extension resulting from the space needed for the compressed spring. Therefore, single-acting cylinders are best suited for applications that only need approximately 6 inches (150 millimeters) of stroke length or less.

Since double-acting cylinders don’t use a spring return, stroke lengths for this design are generally available up to 24 inches (600 mm) in most popular bore sizes. For travel distances longer than 24 inches, there are a number of different rodless cylinder designs that work very well in pick-and-place systems.

Speed Control Concerns

While pneumatic pick-and-place doesn’t offer the speed control and wide range of motion found with electromechanical systems, they can deliver an often acceptable level of speed control by using valves. Flow control or needle valves are used to control the speed of the pneumatic pick-and-place device by regulating the air flow to the actuator. Overall system sizing of valves, tubing and actuators will have an effect on achievable speed range, and greater care should be used if speed is critical.

Grippers and Vacuum Device Deployment

The end effector that picks up the object in a pick-and-place system can be pneumatic grippers or vacuum suction cups both of which are usually lighter, smaller and less expensive than electric grippers.

Pneumatic grippers work well for applications requiring high speeds or a high gripping force. While they don’t offer the force and positioning attributes of electric grippers, pneumatic grippers can be adjusted by using a control valve or an analog proportional pressure valve to change pressure and thus gripping force.

The initial cost of suction cups is low, and they come in a variety of sizes. Suction cups are a good choice for delicate products, such as food and glass, and for flat objects like paper and sheets of metal. While they work for some high-intensity applications, the operational cost of the required vacuum generators may be prohibitive for systems with just a few cups. For inexperienced users, suction cups can also be tricky to implement. Selecting the right size and amount of suction is often more of an art than a science, and determining the size and suction of the cups is often an exercise in trial and error unless considerable experience has been gained in similar applications.

Reducing Total Cost of Ownership

One of the complaints about pneumatic pick-and-place is relatively high operating costs compared to electromechanical systems because they use compressed air. Most pick-and-place systems will operate in settings where compressed air is already being used for other purposes, and several steps can be taken to mitigate air usage. One way to reduce costs is by mounting the pneumatic control components near the point of operation to minimize air line lengths. Locating the valving close to the actuators and using appropriate cylinder and valve combinations can reduce the required air volume by up to 35 percent. In addition, using modern components that are made to reduce leakage and utilizing improved lubricants that operate across a wider temperature range, will extend the life of actuators and valves in your system which in turn reduces the costs of maintenance and replacement. If you would like more tips on making your pneumatic system energy efficient, see this Energy Efficient Pneumatics article.

The Choice is Yours

There are some misconceptions and outdated ideas about pneumatics that can needlessly drive up the cost of pick-and-place by relegating users to higher priced electromechanical systems. When just two positions per axis of motion are required, and when very high speed and extreme precision aren’t required, pneumatic pick-and-place systems will usually be a simpler and less expensive option. And while pneumatic pick-and-place systems have been used for decades, over time they have been improved with technological advances making these time-tested systems a viable choice for many applications.

Originally published: March 21, 2016