Inductive proximity sensors are suitable for many applications. Selecting models with factor 1 capability makes them even easier to deploy for sensing targets of varying metals.

Andrew Waugh, Product Manager for Sensor and Safety products at AutomationDirect, authored an article for the May 2019 issue of Design World titled A Look into Factor 1 Proximity Sensors. Here’s a summary, click on the link above for the full text.

Proximity sensors, also known as prox sensors or prox switches, are solid-state non-contact devices used to sense the presence of metal. They are a great device to accurately sense physical presence in machine and equipment automation applications.

Andrew describes the two major prox switch types, and why the inductive type is preferred for machine sensing.

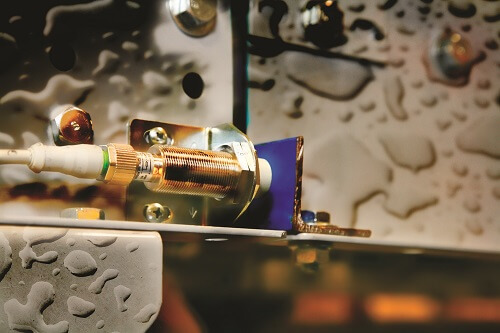

Inductive proximity sensors are specifically designed to sense ferrous metals, while capacitive sensors can detect metallic and non-metallic targets. Inductive technology is preferred for many machine sensing applications for several reasons. Metals are prevalent, rugged, cost-effective and easy to use as targets on machines. Because inductive sensors inherently cannot see other materials, they are not easy fooled by stray materials, dust, water or other environmental elements.

Considerations when selecting the proper prox sensor type include form factor and sensing distance. This effort is simplified by a special class of proximity sensor called factor 1 or K1. Factor 1 sensors incorporate special features to provide a constant sensing range without adjustment, regardless of the target metal.

Standard proximity sensors are available in a variety of diameters and sensing distances, but each must be carefully matched to the application.

Limitations of Standard Inductive Proximity Sensors

Traditional proximity sensors operate by generating and sensing electromagnetic fields using a single ferrite core and coil. Sensitivity is expressed as a k-factor, explains Andrew:

Proximity sensors react to different metals at different distances, making the range dependent on the object material. A nominal target is generally considered to be mild steel, so the correction factor in this case is 1 (or k-factor = 1, sometimes shortened to K1). Other metals with little or no ferrous content will exhibit a reduction in sensing distance, and each sensor manufacturer will provide data sheets indicating the k-factor for certain materials.

For instance, an aluminum target may be sensed at only half the distance of a mild steel target, for an effective k-factor of 0.5.

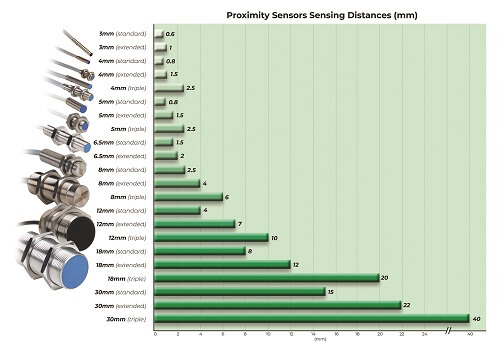

Sensors are available in cylindrical form factors ranging from 3-mm diameter up to 30-mm diameter. Larger diameters generally provide greater sensing distances, and within any give size there may be multiple sensing variants such as standard (1X), extended (2X), triple (3X) and even some quadruple (4X).

Inductive proximity sensors are compact and reliable, providing a suitable way to sense the presence or absence of metal for automation applications.

Factor 1 Sensors Address Issues

End users with diverse sensing needs often want to simplify their specification and stocking effort, and they can do this by selecting proximity sensors offering the same range for any metal target. Common industrial targets other than mild steel are stainless steel, aluminum, copper, brass and more. Ideally, no adjustments or special accommodations would be required to use a sensor, even with different target metals.

Andrew says that in practice, this has been achieved with updated technology delivering proximity sensors with a k-factor of 1 for all metals.

Various approaches enable factor 1 sensors to achieve better sensitivity, while adding discretion to sense the presence of varying metal materials. The result of this technology is a constant sensing range for all types of target metals. This greatly simplifies the design, application, commissioning and stocking of proximity sensors. Factor 1 inductive proximity sensors deliver many benefits over traditional technology, making them the right choice for many new and retrofit applications, especially since they carry little or no cost premium.

Design Considerations

Although K1 sensors should be able to detect all metals at the same distance, it is important to assess each application. K1 sensor product versatility allows a single model to replace several on a machine or system. Andrew points out that the greatest benefit of K1 sensors revolves around the cost versus distance evaluation.

Sensors increase in cost as the sensing range increases, within a given housing size and material type. Looking at a typical 12mm flush sensor, for example, the standard sensing range is 2mm, extended is 4mm, triple sensing is 6mm and quad sensing is a whopping 8mm of range. As the range doubles so, in general, does the cost. K1 sensors can cost around the same as extended sensing proxes and still deliver that same range on any metal.

K1 proximity sensors provide consistent sensing ranges for many metal target materials — and good value when evaluating cost versus sensing distance.

One Ruler?

Inductive proximity sensors are a mainstay for sensing metal presence in all forms of industrial and machinery automation due to their superior durability and reliability. However, traditional sensors have been somewhat application-specific, requiring substantial design effort to select the right sensor. Factor 1 sensor technology is more flexible and easier to use, at little or no cost difference. The choice is clear to move forward with factor 1 inductive proximity sensors in most applications.

To read more articles about sensors, click here.

Where noted: shielded = flush or semi-flush and unshielded = non-flush