Specifying the right electrical enclosure protects personnel and equipment.

Jim Krebs, Technical Marketing Engineer at AutomationDirect, wrote an article for the July 2020 issue of Processing titled Specifying the Right Electrical Enclosure. Here is a summary, click on the link above for the full text.

Electrical enclosures are ubiquitous throughout public areas, buildings, and industrial settings. Although these enclosures are largely unnoticed, they serve a critical role for protecting devices within them and people outside of them. Designers should follow a few steps to ensure they have considered the necessary factors.

By the Book

Industrial enclosures may contain many types of electrical devices—for power, instrumentation, automation, and more—or other components like pneumatics. For any enclosure containing electrical devices, some of the relevant codes, standards, and specifications include:

- National Electrical Code (NEC)

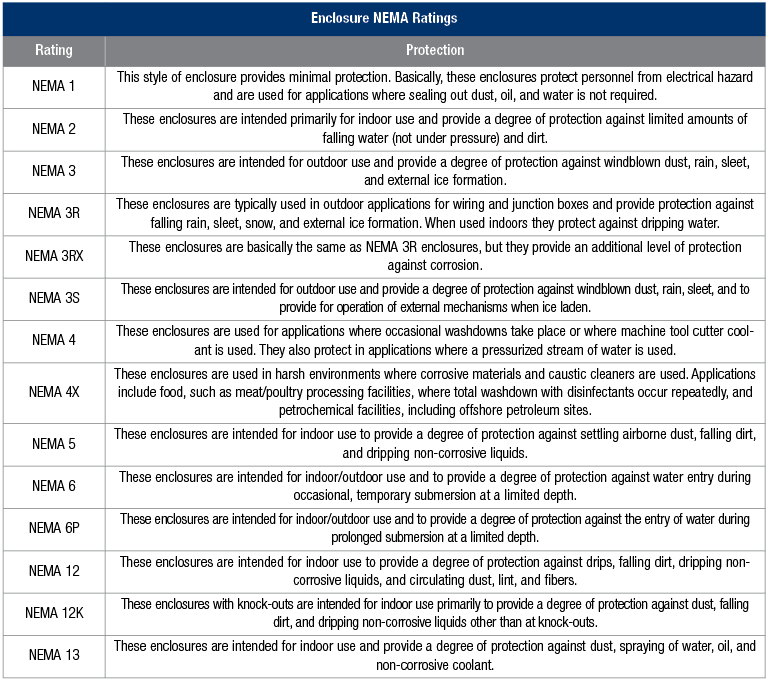

- National Electrical Manufacturers Association (NEMA)

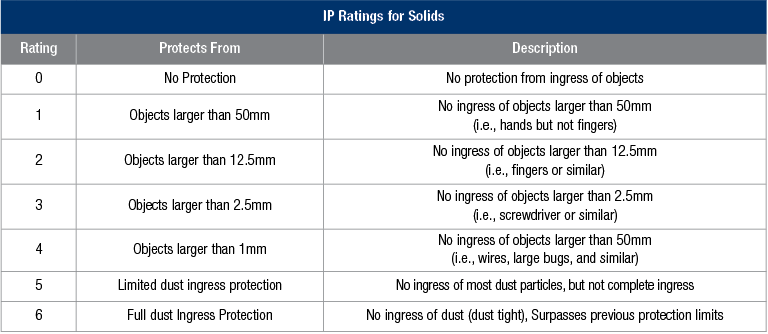

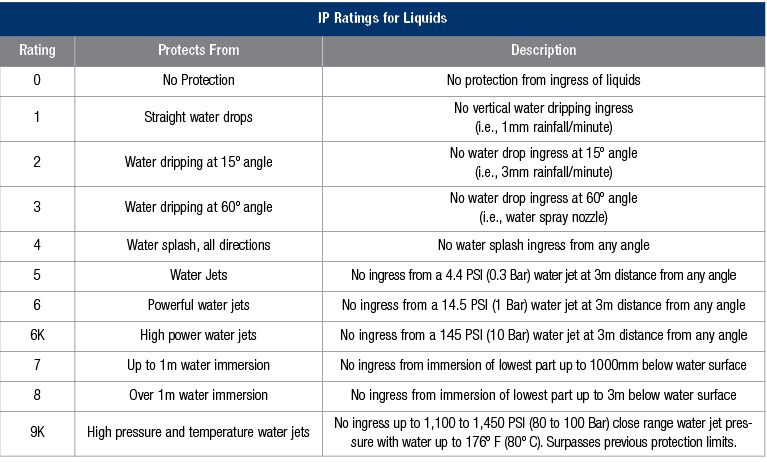

- Ingress Protection (IP)

- International Electrotechnical Commission (IEC)

- Underwriters Laboratories (UL)

- Canadian Standards Associations (CSA)

Designers also must note that some end users and design firms may call for more stringent requirements or allow/disallow certain products.

Form Factors

Enclosures can be basic boxes or may support a significant number of hardwired devices. Common mounting styles are:

- Wall-mount

- Floor-mount (with legs)

- Freestanding (enclosure extends all the way to the floor)

- Consoles, consolets, and pushbutton enclosures (for housing pilot devices for operators use)

- Junction boxes and wireways (to facilitate wiring)

- Slope top (for sanitary use)

Sizing an enclosure requires carefully balancing internal space, external installation room, heat dissipation, and cost. Designers are advised to always review detailed product engineering drawings instead of only website descriptions to ensure exact sizes and interferences are understood.

Protection

NEMA and IEC IP ratings provide guidance as to what level of protection is provided against dirt, water, and chemicals. Enclosures are available in many metal and non-metallic options to meet environmental, cost, and radio signaling requirements:

- Painted carbon steel

- Stainless steel (304, 316, 316L)

- Aluminum

- Fiberglass reinforced polyester

- Polycarbonate

- PVC

- Thermoplastic ABS

Temperature

Components within an enclosure usually generate some heat, yet they must remain within certain minimum and maximum operating temperatures. External conditions, especially sun exposure, can greatly increase heating. There are design tools available to verify thermal conditions—and users can specify venting, fans, air conditioning, or heaters as needed to maintain the required internal temperature and prevent condensation.

Accessories

The enclosure itself is just a box, but there are many accessories to consider:

- Backpanels and subpanels

- Windows

- Fittings to gang modular enclosures together

- Padlocking, key-locking, and/or screw cover clamps

- Electrical interlocks

Choosing the Right Enclosure Options

Specifying electrical enclosures is not exactly rocket science, but the task does require careful investigation, understanding of the options, and proper decision making.

Selecting the proper enclosure requires a series of decisions and sometimes a balancing act among different variables. There is not a perfect checklist for doing so, because many decisions impact other choices, making the selection process iterative.

Selecting and installing the right enclosure will ensure a long lifetime of safe and reliable service.