Human-machine interfaces are available with many hardware and software features. Users should work backwards from the target application to make sure all needs are addressed.

Bill Dehner, a Technical Marketing Manager at AutomationDirect, authored an article for the June 2019 issue of Control Engineering titled Choosing the Right HMI. Here’s a summary, click on the link above for the full text.

End users expect intuitive operator interfaces, and for industrial automation this means using touchscreen human-machine interfaces (HMIs). HMIs are valuable for complementing or superseding the capabilities of switches, buttons and lights in a control panel. The most reliable approach to choosing the right HMI is to examine the specific needs of the target application and work backwards to confirm all necessary options are available.

Weathering the Elements

Any HMI must physically survive where it will be installed by withstanding exposure to water, chemicals, temperatures and other environmental factors. Bill also says another key concern is whether the HMI will be indoors or outdoors.

NEMA and UL ratings commonly are constrained as “indoor use only.” Even the brightest HMIs struggle with sunlight glare outdoors and direct sunlight can cause heat issues. Users should consider locating outdoor HMIs into more protected areas or outfitting them with sunshields.

Brightness is a key indicator of ease of use, and backlight life indicates how long the HMI is likely to last.

HMI Physical Display Size and Interface Considerations

Choosing the right display size is a balancing act. Operators and programmers may prefer larger units, while cost or equipment configurations may dictate smaller sizes. HMI hardware product lines with a range of dimensions offer options.

Touchscreen technology is important for industrial applications. Consumer touch devices tend to use capacitive multi-touch, which usually won’t sense gloved fingers and can be affected by water. Industrial HMIs often employ resistive single-touch technology usable with gloved fingers, often preferred for industrial applications.

Don’t Forget the Memory

HMIs are also defined by memory and processor performance. Careful designers will storyboard the anticipated graphics and do some rough estimates of tag counts to ensure they are within limits. Bill points out some other memory considerations.

HMIs with expandable memory or multiple memory sizes may help to remove constraints. It’s also important to remember advanced features such as on-board calculations and trending and recipes will impact HMI performance, so it’s best to use conservative estimates.

Connectivity Concerns

Connectivity is a key factor when selecting an HMI. Most commonly, users will want an Ethernet port so the HMI can communicate with one or more programmable logic controllers (PLCs). Other options are RS232C serial and USB. More recently, another must-have feature is an HDMI output port.

An HDMI connection can drive a second off-board monitor such as a large-format TV located in the plant or facility. An operator can work locally on the HMI display while other operators can see the larger display from a distance.

Make a Software Checklist

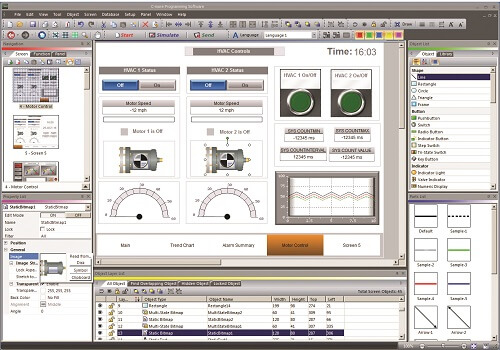

HMI programing software features and the development environment require detailed inspection. Operators will want intuitive and easy-to-use graphical objects, while programmers will look for good import/export support and other efficient methods to speed development. Here are the top 10 runtime features users should consider, according to Bill:

- Basic objects

- Static library objects

- Bitmap capability

- Animated objects

- Preconfigured complex faceplate objects

- Advanced trending and recipe objects

- Security

- Language switching

- Alarming

- Data logging

Advanced features like on-board logic, trigger evaluation and event manager functions may be available—and designers should always pre-test more sophisticated functions.

Extending an HMI’s Reach

In recent years, HMIs have moved beyond basic local visualization. Some offer remote access and on-board web servers, extending HMI functionality in new ways to mobile devices.

Hardware and software features deserve close attention by designers as they select an HMI, and these factors should be considered in addition to hardware/software pricing, warranty duration and availability of free support. Obtaining a test sample of the HMI hardware and software is recommended to prove both will meet project needs. Finally, systems offering a simulation mode at low or no cost are a great benefit for testing.

Click here to read more articles related to HMIs.