AutomationDirect is offering $0.00 cut charges and free same-day shipping on orders over a small minimum to demonstrate the benefits of cut-to-length cable adoption by OEMs, end users, and system integrators.

Jim Krebs, Technical Marketing Engineer at AutomationDirect, wrote an article for the December 2019 issue of Control Engineering titled How to Specify Cut-To-Length Cable. Here’s a summary, click on the link above for the full text.

Every automation system uses significant amounts of wire and cable. Good design practice is to minimize the variety of types and colors to simplify ordering and reduce waste, but consolidation efforts can actually cost more when cables are over-specified to handle more situations. Therefore, many OEMs, end users, and system integrators are shifting to cut-to-length cable services so they can economically obtain exactly what they need, when they need it.

Determine Cable Type

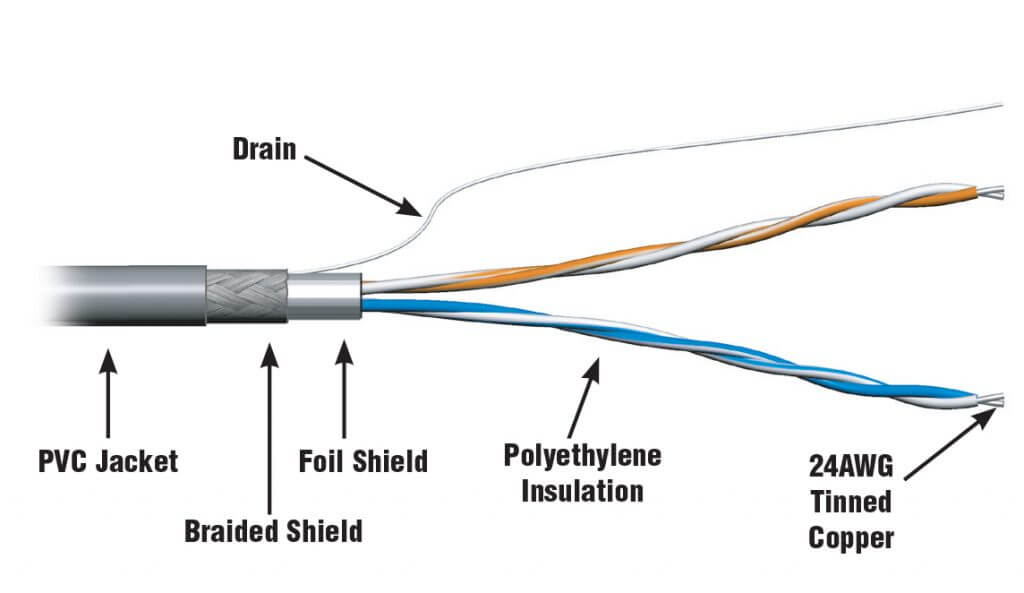

Cables are used for power, input/output signaling, and communications in many different environmental conditions and installation services. The NFPA 70: National Electrical Code (NEC) also has many designations, and there can be confusing generic industry naming conventions. Designers must consider cable materials of construction, ampacity, shielding, and more. With so many variables, it can be tough to select and adequately stock the right cables.

Even a basic cable type, such as flexible portable cords, come with numerous jacket type rating, conductor count, and conductor gauge options.

Cable Business as Usual

Many end users try to stock what they need, but eventually accumulate an inventory of abandoned or out-of-date cable spools. Cut-to-length services can minimize waste and expense, as long as the supplier can readily confirm proper cable types are available, assure quick delivery times, and maintain competitive pricing.

Helping Installers

Following a cut-to-length approach, technicians make the very same installation take-off they normally would, but instead of heading to the stockroom they place an order that is delivered in a day or two to the jobsite. This convenience transforms the cable supplier into a virtual stockroom.

Making the Cut, Certification

Cut-to-length cable suppliers must gear up for the task, establishing an online ordering system and specialized work areas to fulfill the orders with good quality control.

One thing prospective cut-to-length cable customers may not know is Underwriters Laboratories (UL) requires traceability of a cable back to its manufacturer; surface printing on the cables alone isn’t enough to fulfill this requirement. A certified label must be affixed to the spool or cable shipping package from the manufacturer.

Where bulk cable is respooled into smaller quantities, these special certification labels must be applied in a process defined by UL as “Processed Wire – Respooled.” The supplier must also track master reels by lot number.

Cut-To-Length Cables Save Time and Money

The conventional method of ordering and stocking cables isn’t always the best approach, especially with so many product makes and models. Cut-to-length services let end users and OEMs obtain exactly what they need and provide an economical way to test new products. Suppliers offering cut-to-length cable services can’t just send a worker to the warehouse with wire cutters, but must carefully develop stocking, ordering, and UL-certified fulfillment methods.