Modern processing plants need control panels built in accordance with specific design details.

Chris Kregoski, product engineer for AutomationDirect, authored an article for the July 2022 Processing magazine titled Process Control Panel Design Basics. Here’s a summary, click on the link above for the full text.

Processing plants typically incorporate extensive automation. The control panels are usually built in a dedicated shop, regardless of whether they end up installed on OEM equipment, or by a contractor or the end user for a “stick built” installation. While electrical, instrumentation, and controls (EIC) design requires specialized knowledge, end users of all types will benefit from understanding process control panel design concepts.

Following Requirements

Process control panels are designed based on specifications, codes and regulations to meet functional needs and provide safe operation, while protecting the devices within the panel from the environment. They may include provisions for power distribution, PLCs, I/O, HMIs, VFDs, servos, and other components as needed.

Power and Signals

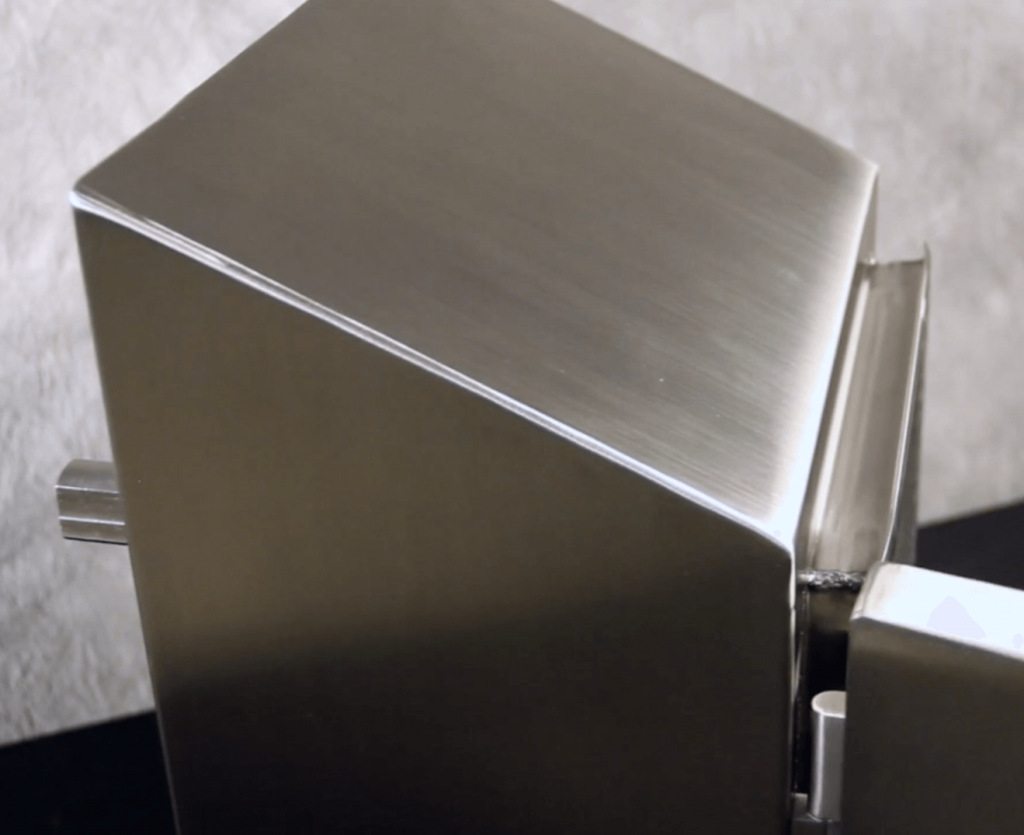

Designers must consider the electrical, control signal, and networking needs for the panel and specify required devices. It is often helpful to create a block diagram to identify the relationship among these components. Once the components are selected, an enclosure can be sized. The enclosure may be painted metal, stainless steel, or fiberglass—in each case selected to resist environmental conditions including dirt, moisture, and chemicals. Food, pharma, and similar sanitary installations may require special hygienically-designed enclosures.

It is also critical to understand the heating and cooling needs of internal panel components in relation to the external environmental conditions (ambient temperature, sunlight exposure) so that the proper equipment can be added to control the temperature and humidity within acceptable limits.

Drawing Package

Designers typically create a detailed drawing package, which should include a cover page, drawing list, bill of materials (BOM), nameplate/tag schedule, cable/wire lists, dimensioned interior/exterior layouts, power distribution drawings, and control wiring drawings. There are many other considerations such as power calculations, conductor sizing and UL and code compliance, but a good drawing package will define all the required work in sufficient detail to meet the project needs.

Time to Test

Thorough testing is needed to verify assembly, prove out the wiring, and demonstrate basic power-on conditions. More advanced tests may exercise the functionality of PLCs, HMIs, and VFDs.

Industrial process control panels are more than just boxes stuffed with some electrical parts. Properly designing, assembling, testing and installing these control panels for safe and reliable operation—especially for operation in challenging field locations and using advanced automation devices—requires skilled personnel.

The AutomationDirect website provides a complete portfolio of enclosures, components, PLCs, HMIs, VFDs, accessories, and more. Design tools and helpful online/phone support are also available to help OEMs, systems integrators, and end users design and deploy process control panels.