Electro-pneumatic I/O and solenoid systems save control panel space while simplifying installation and maintenance.

Machine builders and OEMs everywhere are striving to meet customer demands to deliver smarter, more modular, and physically compact systems—often requiring more instrumentation and control points. In a Fluid Power World January/February 2024 article titled Distributed Electro-Pneumatics Streamline Equipment Designs, AutomationDirect’s Chip McDaniel explains how many designers are taking advantage of distributed electro-pneumatic input/output (I/O) and solenoid valve bank systems to reach these goals.

Moving from Centralized to Distributed Automation

Classic automation designs have long used main control panels housing centralized programmable logic controllers (PLCs) and I/O. The control panels needed to be big enough to house all the components, and this approach required significant amounts of wiring and tubing to be installed on the equipment.

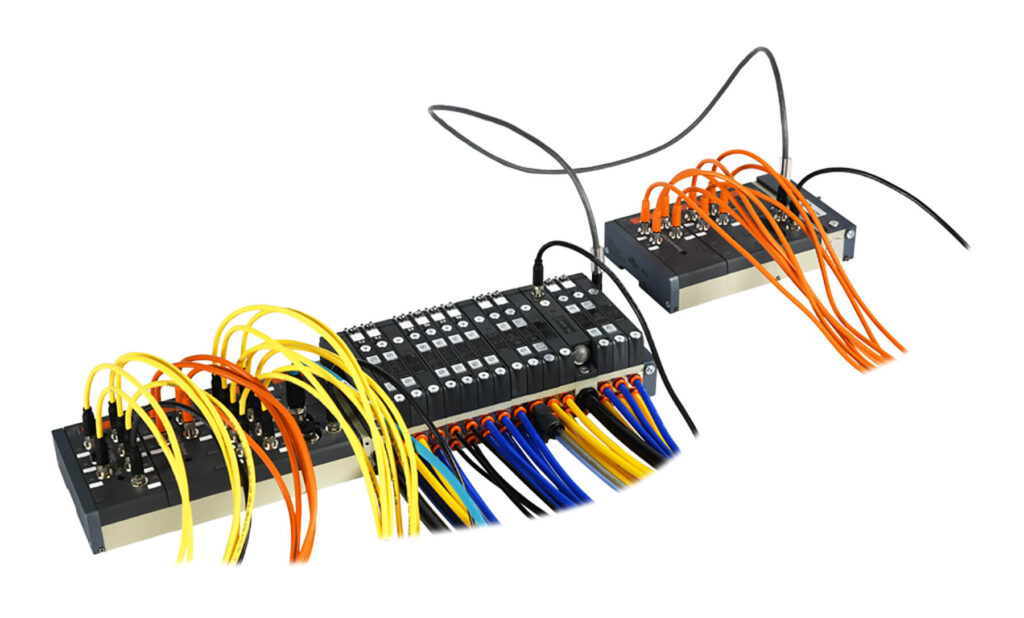

A newer and more elegant approach, made possible by electro-pneumatic I/O and solenoid bank assemblies like the AutomationDirect NITRA pneumatic automation link (PAL), is to distribute signaling throughout an entire machine. Modular electro-pneumatics like the PAL are a compact and organized way to install I/O signals and pneumatics outside of control panels, surface mounting them close to the field devices.

The PAL system is:

- Modular, so designers can configure exactly what they need, and design equipment with convenient shipping splits to support rapid field installation

- Scalable, able to handle just a few points or many

- Connectorized, using M8 and M12 quick-disconnect electrical connectors and push-to-connect pneumatic fittings, so they can be rapidly installed and easily maintained

- IP65 rated, to withstand dust and light pressure water sprays

A range of I/O modules in 24VDC discrete and analog inputs and outputs is available, and solenoid modules can be 3/2, 5/2, and 5/3 center-closed variants. Modules connect to various base sizes.

Making a Complete Connection

When using distributed electro-pneumatics, designers plan for main power, air, and communications connections to be distributed to each PAL. The connections from the PAL to the field devices are minimized, which streamlines installations.

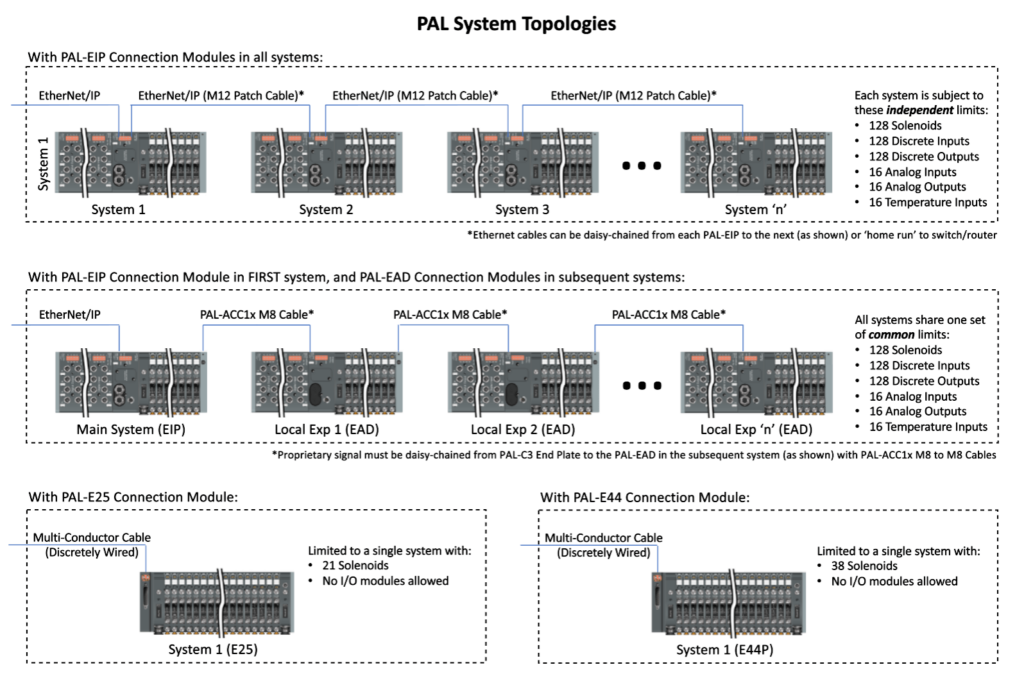

Many installation topologies are available. The PAL offers multi-conductor hardwiring options, but electro-pneumatic components are even more effective for minimizing wiring and maximizing data transfer when they are implemented using an industrial Ethernet protocol, such as EtherNet/IP.

One concern that designers might have is how to properly select and configure such a flexible system arranged from many components. To address this issue, AutomationDirect has created a comprehensive online PAL Controller Configuration software tool. This tool makes it simple for designers to select the communication controller, I/O signal modules, and solenoids, and to define the EtherNet/IP mapping for all signal, control, and diagnostics data. PLC provisions are available for scanning and discovering PAL assemblies connected to a network.

As machinery builders and OEMs look to deliver equipment more efficiently with greater intelligence, electro-pneumatic I/O and solenoid systems are leading methods for hitting these targets.

Visit the AutomationDirect website to discover how the PAL electro-pneumatic I/O and solenoid systems, and many other products, can help you create smarter and more streamlined equipment designs.