Micro-PLCs with Wi-Fi are key enablers for quickly and economically adding IIoT data connectivity to any type of new or legacy equipment.

Bill Dehner, technical marketing engineer for AutomationDirect, wrote an article for the October 2021 issue of Fluid Power World titled Streamlining Equipment IIoT Connectivity. Here’s a summary, click on the link above for the full text.

Heavy-duty, pneumatically- and hydraulically-operated equipment is widely used for manufacturing and production tasks, but many times these machines lack convenient connectivity and data access. Because so many end users are accustomed to accessing and viewing information on consumer devices, they are beginning to look for the same capabilities for production equipment.

Adding IIoT to Smaller Systems

End users are often intimidated by the idea of reworking legacy equipment to add IIoT capabilities. Fortunately, there is a way to leave the existing systems as-is and to simply add IIoT functionality using simple and low-cost cloud-capable controllers.

This scalable approach is useful for just a few data points and is easily expandable. Basic connectivity provides valuable visibility and information about the machine operational status and performance, and it is the first step to more advanced capabilities like data logging, analytics, and reporting.

Inexpensive Implementations

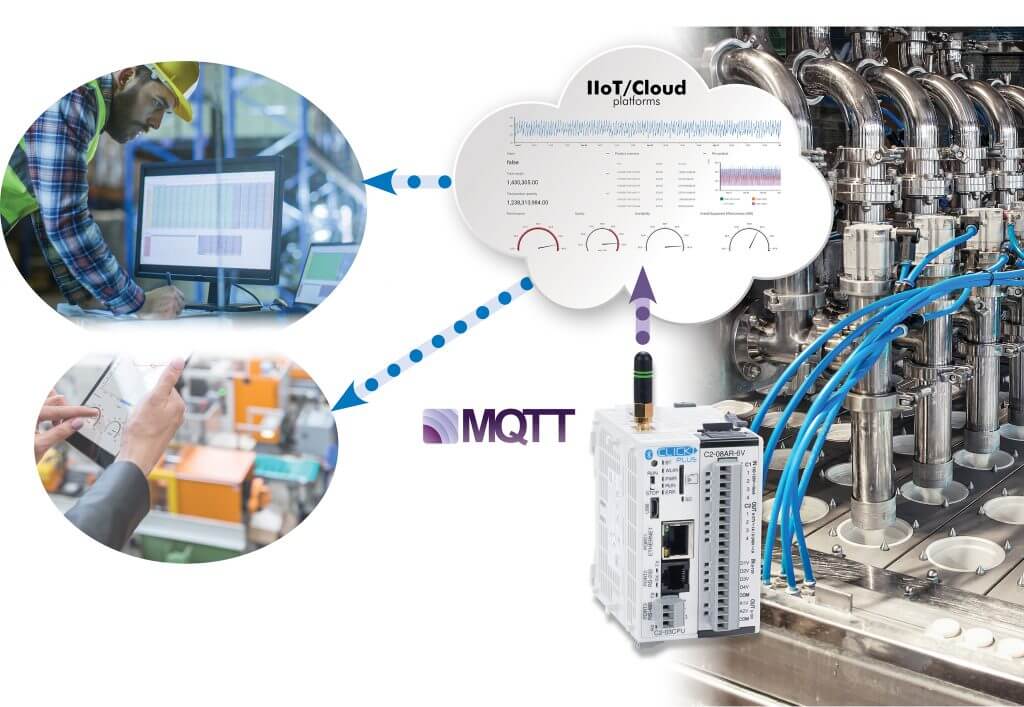

AutomationDirect CLICK PLUS micro-modular PLCs combine a compact industrial form factor with Wi-Fi, support for multiple communications protocols, and cloud connectivity. This means they can connect to basic wired I/O signals, and they can even communicate with intelligent devices using methods such as Modbus, EtherNet/IP, and more. Wired Ethernet and Wi-Fi can be used with the MQTT protocol for transmitting data through firewalls and up to the cloud. Bluetooth connectivity and free, easy-to-use software help users get systems up and running quickly.

IIoT in the Field

Consider a system with many makes, models, and vintages of equipment distributed across multiple production lines or trains. Micro-PLCs can be installed one at a time during brief downtime periods on the most important systems, wired in parallel to monitor running status, trouble conditions, and other key performance indicators.

Initially, operators can easily monitor systems using a mobile tablet. As more systems come online, plant personnel can compare and analyze performance. Eventually, the data can be logged for deeper analysis.

Simplified and Scalable Edge-to-Cloud

End users are looking to improve the efficiency of existing assets.

Manufacturing and production companies everywhere typically operate many legacy machines, but they are challenged with obtaining a birds-eye view of performance. Traditional methods of adding typical PLCs, PCs, and software can be used to address this issue, but this often requires a level of cost and effort exceeding the benefit.

New options, like the AutomationDirect CLICK PLUS micro-modular PLC, are helping end users rapidly add IIoT capabilities in a streamlined and standardized way.