A wide range of products support reliable and safe electrical circuit designs for any application.

By Billy Sonnenthal, AutomationDirect

Key takeaways

- Electrical circuit protection prevents fires, equipment damage, and injury by interrupting abnormal current caused by overloads, short circuits, and ground faults.

- Overcurrent protective devices (OCPDs)—such as fuses and circuit breakers—must be properly selected and coordinated to safely interrupt fault currents without damaging the system.

- Codes and standards matter: Electrical designs should follow the National Electrical Code (NEC), use UL-listed devices, and align with OSHA safety requirements to reduce risk and ensure compliance.

- Not all protection devices serve the same purpose—fuses, MCBs, MCCBs, and disconnects differ in response time, interrupt ratings, and application, making correct selection critical.

- Effective circuit protection starts at the design stage, requiring accurate load calculations, fault current analysis, and consideration of environmental and operational conditions.

Nearly every electrical or control panel—whether destined for a home, office, or busy factory—features an incoming power circuit, internal power distribution, and connections to/from field devices. Careful hardware selection and compliance with electrical codes and standards are essential to safeguard every circuit.

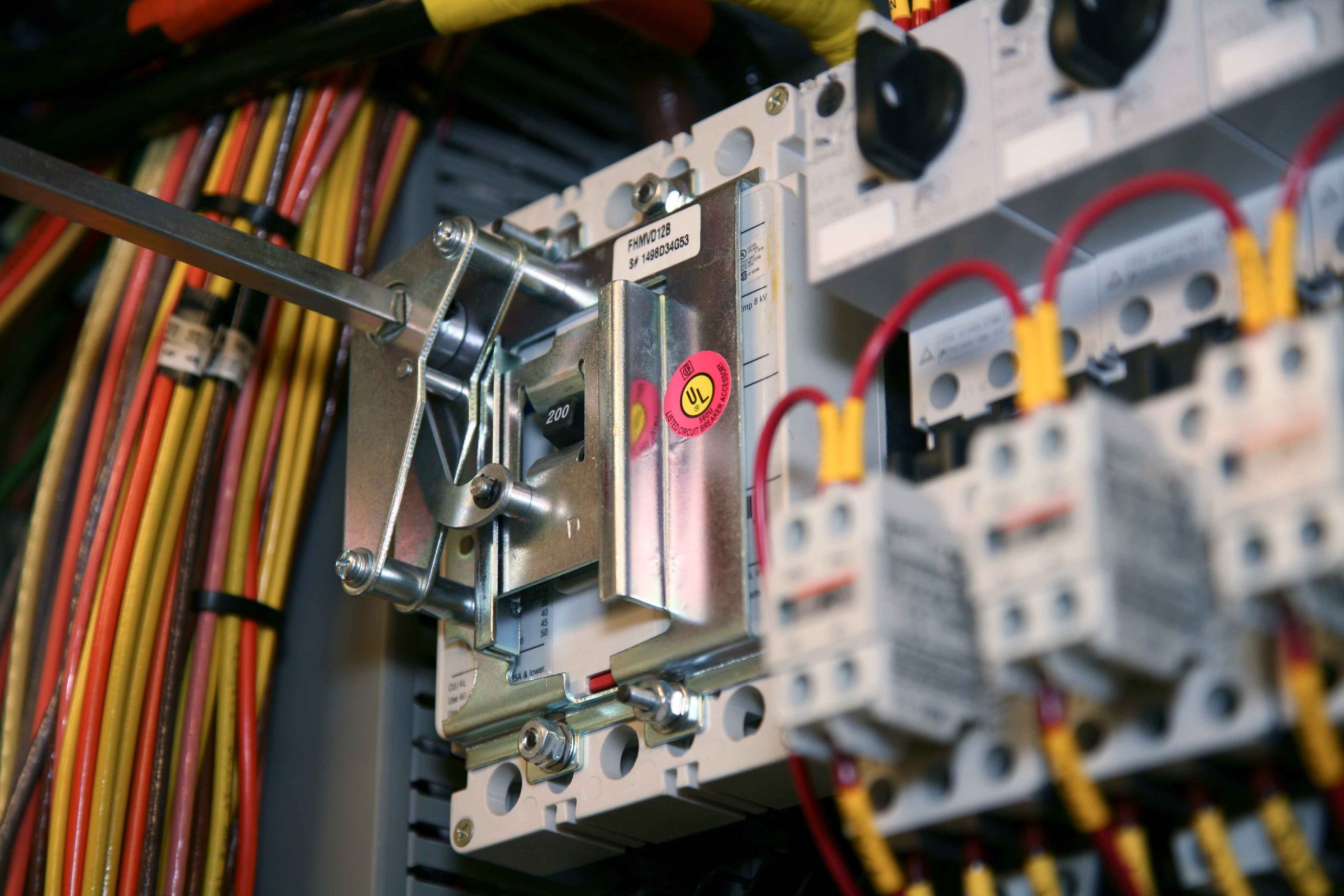

Panels may house digital controllers, hardwired relays, voltage transformers, motor starters, variable frequency drives (VFDs), and other electrical devices, but they all share one non-negotiable requirement: robust circuit protection engineered to prevent costly failures and dangerous hazards (Figure 1). The path to safe and reliable panel designs is paved by designers and engineers who immerse themselves in the relevant codes, standards, and best practices, and specify effective electrical circuit protection products.

If you need a refresher on national safety standards you can view them here:

- NEC electrical safety standards

- UL standards for electrical protection devices

- OSHA electrical safety requirements

What can go wrong?

Electrical problems can lead to downtime, damage, and dangerous conditions. While improper designs are more likely to result in electrical issues, a correct design will properly handle trouble. Common failure modes which must be addressed include:

- Overload: When an unacceptably high electrical current flows, such as due to a too-heavily-loaded motor, or too many items connected to a circuit.

- Short circuit fault: When energized conductors are inadvertently connected to each other or to neutral.

- Ground fault: When energized conductors are inadvertently connected to ground.

These and other failures can cause varying degrees of overheating, thermal damage, fire, or arc flash explosions. Short circuit and ground faults—which occur when conductors directly or indirectly connect due to mechanical damage, degraded insulation, or the introduction of a conducting medium like water—are a particular problem due to the resulting fault current, representing an extreme spike compared to typical overload conditions. This can cause an arc fault, which occurs through the air, and is especially dangerous because of the light, heat, and rapidly expanding shockwave produced.

Creating Safe Electrical Designs

Due to the many possible hazards associated with electrical circuits, codes and standards have been developed to define how to avoid and handle faults. Depending on the application, installation location, industry, and other criteria, there can be several applicable codes and standards, but some of the most well-known are:

- National Fire Protection Association (NFPA) 70 “National Electrical Code” (NEC)

- UL Solutions 508A “Standard for Industrial Control Panels”

- International Electrotechnical Commission (IEC) 61439 “Low-voltage switchgear and controlgear assemblies”

In accordance with the codes and standards, designers must calculate the electrical loads and evaluate the available fault current (AFC)—as well as the short circuit current rating (SCCR) of each device—to ensure proper coordination.

A key component for guarding against electrical circuit problems is an overcurrent circuit protection device (OCPD), which is designed to reliably open an electrical circuit even while withstanding potentially high fault currents.

Electrical and control panel designers typically follow these steps:

- Define devices: Select hardware—including components like relays, controllers, and motors, as well as the power supplies to operate them—to accomplish the needed functionality.

- Size OCPD components to carry the normal electrical loads they will supply while protecting supplied elements.

- Size the conductors, including the terminal/distribution blocks, to connect them.

- Verify the SCCRs for all devices are appropriate.

- Provide physical protection: Components are commonly located within an enclosure to protect them from mechanical damage, moisture, and temperature extremes.

- Repeat this design cycle as needed until all conditions are satisfied.

Electrical Circuit Protection Components

There are several types of OCPDs, and there are many other associated electrical circuit components. Following is a summary of the main categories.

Disconnects

Disconnects basically work as electrical open/close switches, although versions are also available with fuses. There are many form factors, and a circuit breaker can act as a disconnect. Electrically powered equipment usually requires a disconnecting means, with lockout/tagout (LOTO) provisions, to help users clearly and easily isolate electrical energy from components.

Distribution

Electrical distribution is handled by conductors—typically wires and cables, but also busbars—connected to terminal blocks, distribution blocks, and associated connectors.

Fuses

Fuses are a traditional overcurrent protection method that come in a wide range of current/voltage ratings and fuse holder form factors, providing a relatively low-cost option with a high short circuit current interrupting rating (such as 10kA, 100kA, or even larger). They are thermal devices, with internal portions that melt to open the circuit if the current is too high, so they are single-use and must be replaced after operating.

Molded Case Circuit Breakers (MCCBs)

MCCBs are automatic electrical devices, used to protect against overload and fault currents in power circuits (Figure 2). They open or “trip” automatically upon fault connections, and can be reset and then closed when the problem is removed. MCCBs have a higher initial cost than fused installations, but provide a long operating life. They are designed to comply with the UL 489 standard, and are available in sizes from 15A up to many hundreds of amps. However, their short circuit current interrupting rating is lower than that of fuses, ranging from 22kA to 65kA.

Miniature Circuit Breakers (MCBs) and Supplementary Protectors

MCBs are smaller size circuit breakers, also designed to comply with the UL 489 standard, and available in sizes starting at 0.5A with short circuit current interrupting ratings of 14kA or less (Figure 3). Supplementary protectors are like MCBs, but they are designed to comply with UL 1077 and provide additional, although limited, protection in conjunction with an upstream MCB.

Creating Safe Electrical Circuit Solutions

There are many more possibilities when it comes to electrical circuit protection. Motor power circuit protection is a specific category, and there are other products such as electronic circuit breakers (ECBs), ground fault protection, and power quality protection, to provide even more advanced safeguarding. The AutomationDirect website provides a complete portfolio of electrical circuit protection products, related components, and information resources to help designers create reliable and safe solutions.

Bill Sonnenthal is a technical marketing engineer at AutomationDirect. He has worked at AutomationDirect since 2009 in technical and marketing roles, and he holds a BSEE degree from the Georgia Institute of Technology. Before joining the company, Sonnenthal spent 15 years designing, programming, and commissioning control systems in the newspaper and printing industry.