Intelligent routers and associated cloud services make it easy for end users and OEMs to use an IIoT approach for accessing and acting on operational data.

Bill Dehner, technical marketing engineer for AutomationDirect, wrote an article for the September 2021 issue of Plant Engineering titled Exploit IIoT to Improve Operations. Here’s a summary, click on the link above for the full text.

A race is underway to find the best ways to extract factory data and connect it with cloud computing services. The finish line may be a little hard to discern, but end users and OEMs alike want to collect this data, and then use third-party apps or their own self-developed analytics to gain value by improving their operations.

Connecting OT systems up to on-site and cloud-based IT resources is the foundation of any IIoT or Industry 4.0 project. However, stitching together a reliable and secure field-to-cloud data connectivity solution—with the right hardware, software, and networking—is a tall order. For these reasons, AutomationDirect has created a complete off-the-shelf solution so anyone can easily take advantage of the IIoT to improve operations.

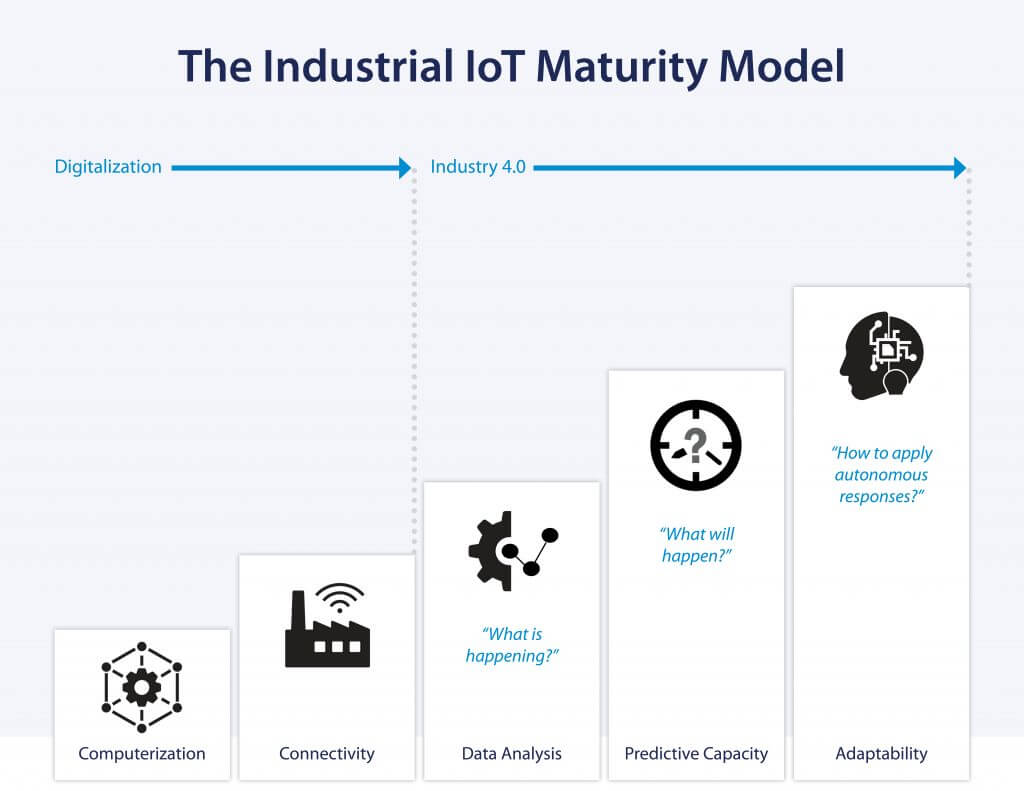

Progressive Digitalization

An IIoT maturity model can help users identify their current digitalization level and show where they can progress. Many users already have PLCs and PCs for automating and computerizing operations, and good on-site networking. The next steps require gathering, analyzing, and acting on data—tasks which are more well-suited to cloud-based computing solutions. Some users might create their own software, but most will find it easier to leverage widely used systems like Microsoft Power BI and Azure, Tableau, or Ultimo.

IIoT Basics

For conveying data to the cloud, and making it accessible to users and applications, developers need solutions with:

- Intelligent routers for connecting to many PLCs and HMIs

- Support for common OT communication protocols

- Simplified cloud data logging (real-time and historical)

- Multiple IT integration methods, such as an API and web hooks

- Flexible licensing and management services

- Comprehensive security support, certified to ISO 27001

- Connection reliability

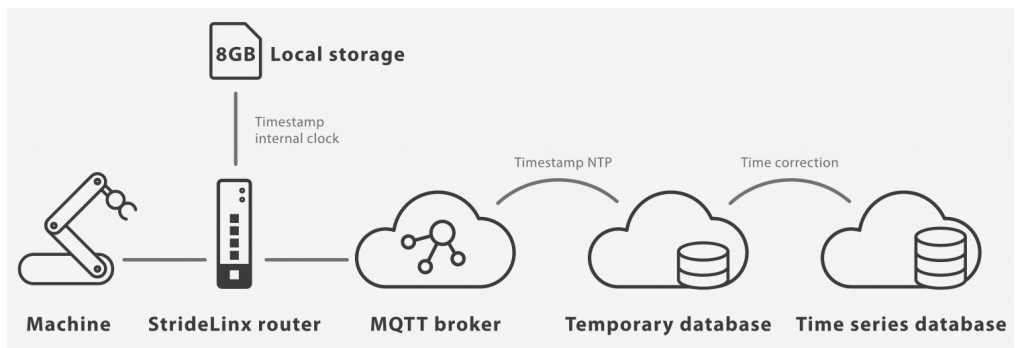

One of the best architectures to make this possible uses an AutomationDirect StrideLinx intelligent router on-site, which can be remotely configured via the cloud, to seamlessly connect with PLCs and HMIs, and to transmit data to the StrideLinx cloud platform. An associated mobile app makes it easy for authorized users to access data, without requiring complex software development.

Secure and Reliable

Cybersecurity is a complex subject, and it is difficult to address with a do-it-yourself approach. This is why many prefer an off-the-shelf solution, such as AutomationDirect’s StrideLinx, which is certified to ISO 27001 requirements and incorporates firewalls, two-factor authentication, third-party audits, and more to provide the best possible protection.

To improve reliability, the routers use redundancy in the form of primary/secondary networks over wired Ethernet, Wi-Fi, or 4G, and can even buffer data to on-board memory during an outage. The cloud services operate on redundant servers distributed throughout data centers worldwide.

Simplifying IIoT

Creating a complete field-to-cloud IIoT solution from scratch is not practical for many end users or OEMs. A better option is using AutomationDirect StrideLinx intelligent routers and cloud services. End users can start small by adding connectivity to one machine or system, and then scale up to monitor production or energy usage. OEMs can include equipment and condition monitoring as a white-labelled, value-add services for their customers.