Using the cloud for data logging and remote access can improve operations, cut costs and simplify interactions.

Jonathan Griffith, product manager for Industrial Communications & Power Supplies at AutomationDirect, wrote an article for the April 2019 issue of the Applied Automation supplement to Control Engineering and Plant Engineering titled Working with the cloud. Griffith says implementing cloud-based remote access is often the first step to implementing Industrial Internet of Things (IIoT) and Industrie 4.0 applications for improved data visualization.

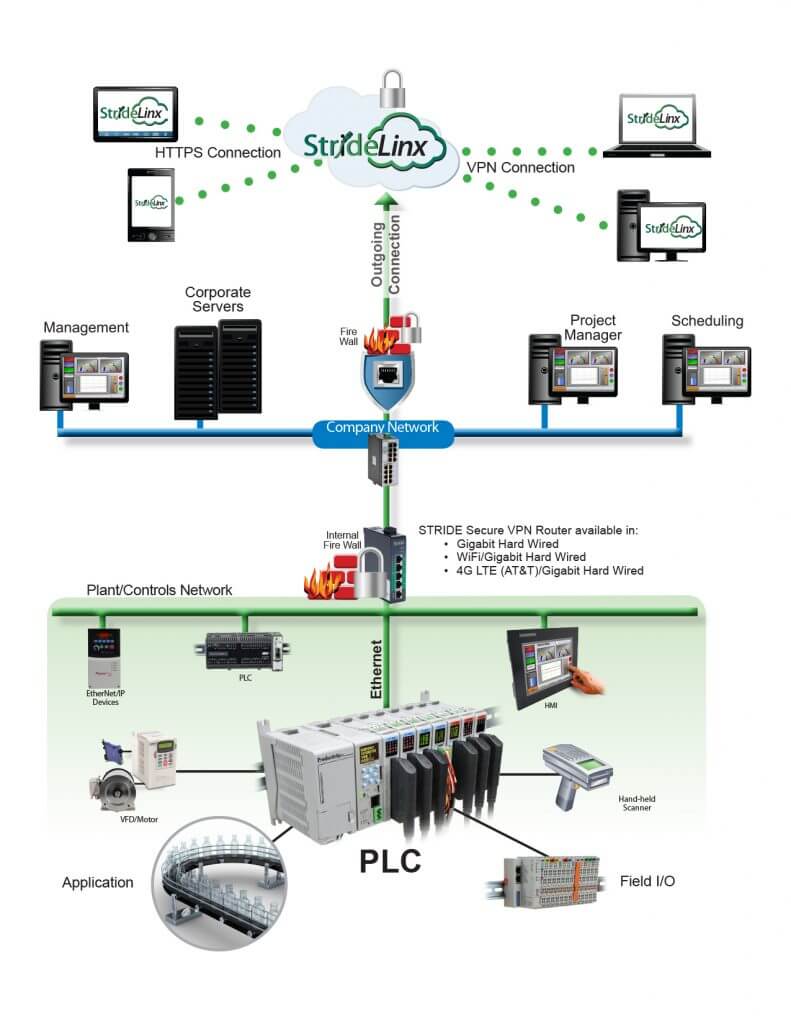

There are several advantages of cloud-based data storage and access systems as compared with on-premises systems. Worldwide cloud connectivity only requires access to the Internet via a wired, Wi-Fi or cellular link. On-premises connectivity is considerably more complex, particularly for users located offsite.

Data storage in the cloud and access to it allows users to gain insight through data visualization. Configurable dashboards using widgets for remote viewing allow visualization of cloud-based data from any device connected to the Internet such as a laptop, a PC, a smartphone or a tablet.

Cloud-based applications allow users to access and visualize data from anywhere to gain insight to a machine or process.

Cloud-based applications allow users to access and visualize data from anywhere to gain insight to a machine or process.

Data logging

Data logging can be local, cloud-based or a combination of both. Many programmable logic controllers (PLCs) and human machine interfaces (HMIs) include onboard memory for local data storage on an SD-card or a USB drive. An industrial plant or facility also may have network-based database servers maintained by the IT department.

This AutomationDirect C-more human-machine interface (HMI) touch panel provides local data logging to an SD-card or a USB drive.

However, with data logging to the cloud, the possibilities are much greater. It’s possible to create and maintain a cloud-based data system, or to use an end-to-end solution offered by a service provider.

Creating a cloud-based data system requires some level of IT expertise, albeit less than doing so on-premises. For example, Amazon Web Services (AWS) is a popular cloud services provider, offering many of the features needed for those wanting to host their own cloud-based data systems.

Although every data logging solution does not have a VPN router, using one provides the required security along with remote access and programming functionality.

AutomationDirect’s StrideLinx secure hosted VPN routers serve as a key component of an end-to-end remote access and data logging solution.

Protocols and Router Configuration

While industrial Ethernet protocols have been advancing, some newer protocols such as message queuing telemetry transport (MQTT) are often a better solution. MQTT has become one of the most common protocols for data logging to the cloud due to its low resource requirements and excellent reliability, even over low-bandwidth networks. Instead of using a request-response system where clients constantly poll for new data from a server, MQTT uses a publish-subscribe methodology.

One popular end-to-end solution uses a VPN router with support for multiple industrial protocols including Modbus TCP, EtherNet/IP, Siemens S7, OPC-UA, BACnet and others—allowing data gathering from any components supporting these protocols, such as PLCs and HMIs.

These StrideLinx Remote Access VPN routers from AutomationDirect offer secure remote access with a subscription-based data logger and notification included.

Data Manipulation and Notification

Once the data is logged to the cloud, users need a way to visualize it. Many end-to-end solutions allow live monitoring and creation of widgets for data visualization.

Widgets can be used to display live and historical data as a number value, or as a Boolean status such as true or false. Through simple configuration, users can enable a cloud notify function to alert workers based on predefined machine or process conditions. These notifications can be categorized as low, medium or high priority—allowing users to choose which notifications they’d like to receive.

The Cloud for All

The cloud works well for small, medium and large companies logging, accessing and visualizing data. The cost of entry is very affordable hardware and a data subscription (free or a monthly fee based on data usage and the service provider), and configuration is quick.

For example, consider Woodwest Controls, a Colorado-based system integrator. The company works on brewing, wastewater and other projects.

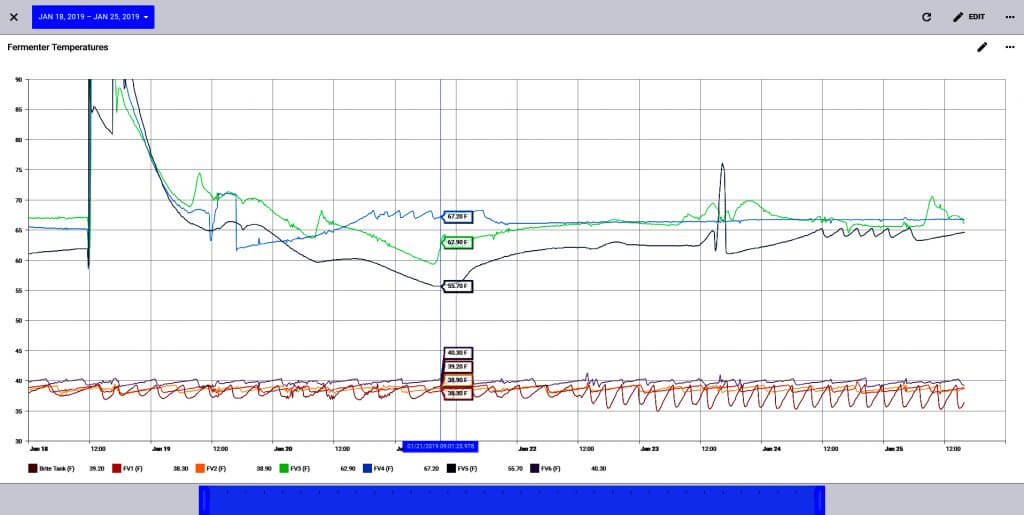

Woodwest Controls uses AutomationDirect’s StrideLinx solution to monitor automation systems installed at their customers’ sites. The main components of these systems are typically an AutomationDirect HMI and PLC. At a microbrewery, the PLC controls temperatures in the fermentation and brite tanks. These tanks need to be held at specific temperatures, which must be monitored closely by the brewer.

Fermentation vessel temperature data logged to the cloud is visualized as live graph data using AutomationDirect’s hosted VPN solution.

The temperatures of 14 fermentation vessels and six brite tanks are monitored using one dashboard with two panels, one for fermentation tanks and one for brite tanks.

Everyone’s IIoT

Griffith says when it comes to the cloud, think big:

There is much that can be done with data logged to the cloud and accessed from it. This data can be used to improve efficiencies in machines and processes. Users can take advantage of these connections to stay informed about production volumes, process status, system alarms, raw material usage, energy consumption, maintenance needs and more. With the right technology, it’s easy to start small and experiment with remote access and data logging at one site, and then scale up and deploy to other production lines and sites.

To read more articles about communications, click here.