Proactive risk mitigation strategies and enhanced technologies are leading more end users than ever before to adopt industrial automation mobile access.

Bill Dehner, technical marketing engineer for AutomationDirect, wrote an article for the November 2021 issue of Plant Engineering titled Industrial Access On the Go. Here’s a summary, click on the link above for the full text.

Most consumers are comfortable with—and even reliant on—easy access to information, technologies, and personal communications using their mobile devices, like phones and tablets. These same commercial trends are making their way into the industrial sector, and to gauge the progress, AutomationDirect surveyed industrial users back in June 2016 and now in August 2021. We found that in 2016, only about 28% of respondents were using mobile devices, but in 2021, the number has increased to 62%.

Meaningful Mobile

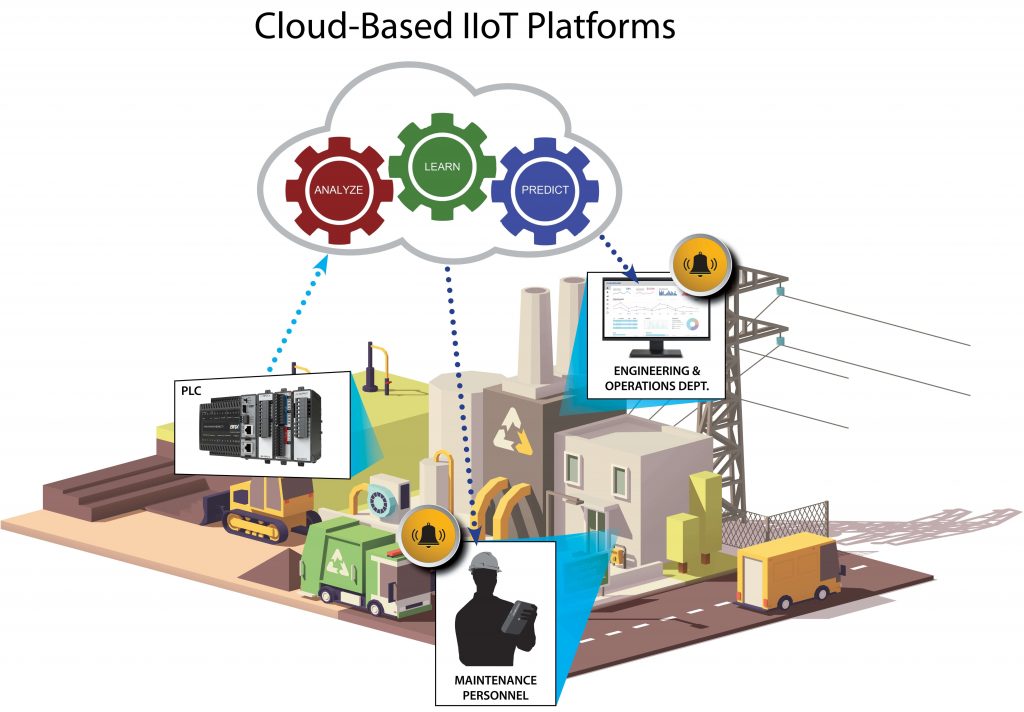

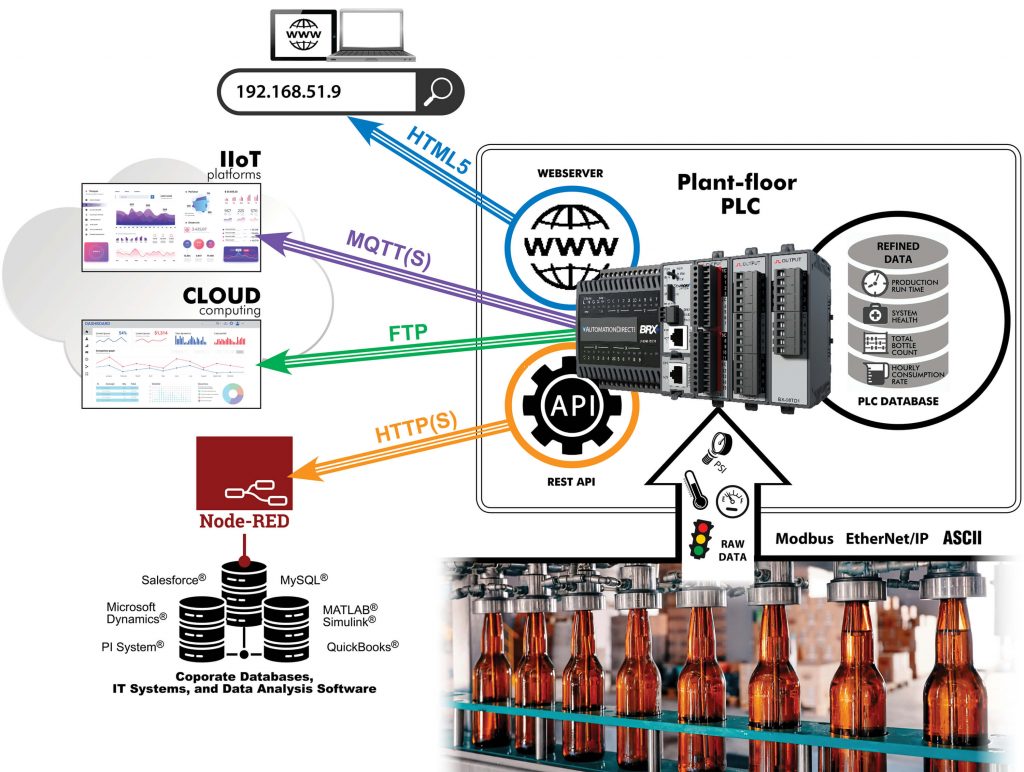

Mobile connectivity takes on many forms. Users can connect to PLCs, HMIs, or other intelligent devices. This may be performed only on-site, or worldwide via the cloud. They may use solutions like AutomationDirect StrideLinx, or they may connect via other providers such as Microsoft Azure®. Some users only need to see a few data points, while others seek a rich visualization and analytical experience.

Who Uses Mobile?

Operations personnel can use mobile access on a daily basis to monitor and control systems. Subject matter experts, located anywhere in the world, can respond to calls for assistance with mobile access. And maintenance techs can act quickly on trouble notifications delivered via mobile. Over 80% of respondents find that mobile connectivity, visualization, and data access are somewhat or very important.

Cybersecurity is a Leading Concern

Despite the benefits, some end users have not yet implemented mobile access. Among those who haven’t, 80% cited security concerns. This is why AutomationDirect has gone to great lengths to ensure necessary security features are built in to devices, and secure communication protocols and services are available.

There are some secondary issues—like how much can really be done on a small screen, and management of company-owned and especially user-owned devices on the plant network. However, over 70% of respondents using mobile now indicate that the capabilities meet or exceed expectations. Convenience and flexibility are key benefits.

Mobile Access Lets End Users Hit the Road

It is clear that the industrial automation sector is progressively adopting mobile technologies, especially as cybersecurity, performance, and ease-of-use concerns are addressed.

Mobile industrial automation access is here to stay, and all signs are that it is delivering value today and will continue to improve.

AutomationDirect has many product and service options to help users evaluate the technology, and choose a right-sized approach that meets their needs and provides future scalability.