Periodically, the AutomationDirect team reaches out to industry users in a variety of ways to gauge their interest on a variety of topics. For instance, in June 2016 we looked into whether users were “data-driven”. One of the questions in that survey addressed whether data was being accessed remotely via a web browser/client or mobile device. While about 60% of respondents were accessing data remotely, less than 30% were using mobile devices.

Because hardware, software, and networking technologies and options have improved greatly over the last five years, we thought it was time to revisit this subject, but this time with more of a focus on mobile devices. So, in August 2021 we created a survey that garnered 157 responses. Here’s what we found.

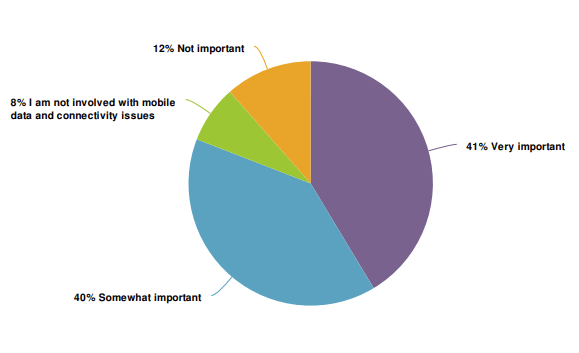

How important to you is mobile connectivity, visualization, and data access for your industrial automation systems?

Mobile access is somewhat or very important to over 80% of respondents. That doesn’t mean they have implemented it yet, but the wide range of mobile options in the consumer and commercial arenas are likely prompting users to look for the same flexibility with their industrial systems.

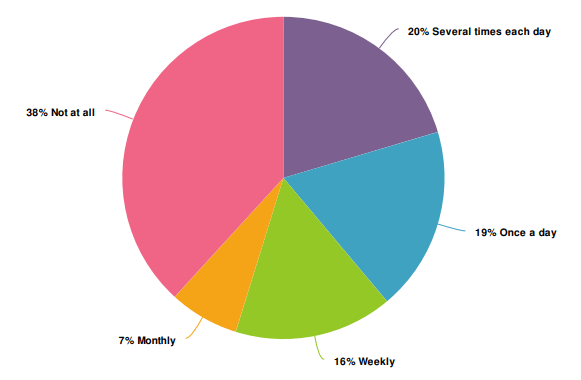

How often do you connect mobile devices to your industrial automation systems?

For those industrial automation users already using mobile devices, the majority connect them one or more times a day. This implies they are getting information that is valuable enough to check frequently. Lower interaction rates might be associated with uses such as periodic maintenance or reporting activities.

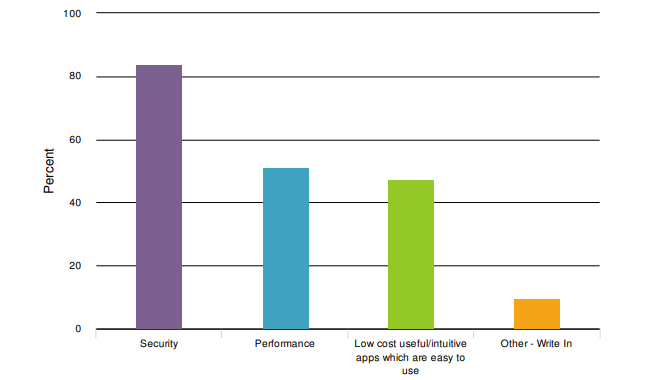

If you don’t currently use mobile access, what features are needed, or concerns must be met for you to start? (select more than one if needed)

Security is a top concern for more than 80% of respondents. Other than that, many users want to ensure performance is suitable, and that mobile access is easy and cost-effective to implement. Some write-in answers noted that there are other potential challenges, such as specifying procedures and policies for using mobile devices in a facility, obtaining IT and OT approval, and developing compelling use cases compatible with small displays.

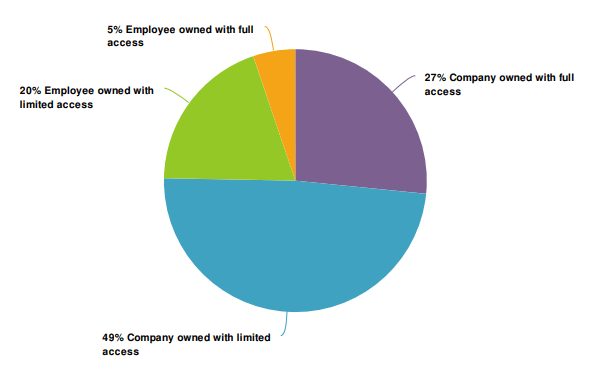

Are the mobile devices employee-owned, or company owned, and how do you manage access?

For those users accessing their industrial systems with mobile devices, about 75% of the time the devices are company-owned, and the remainder of the time the devices are employee-owned. It looks like most users find it easier to manage access using company-owned devices.

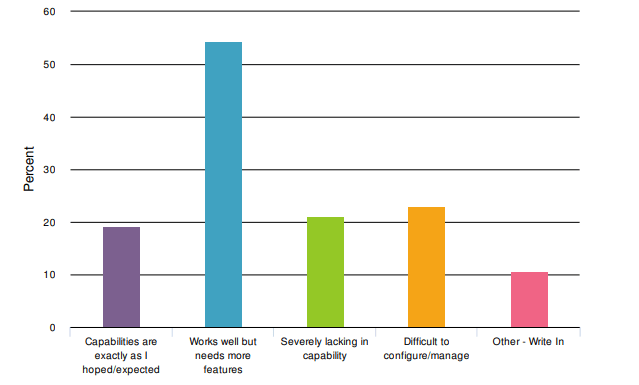

How do you feel about the mobile connectivity experience? (select more than one if desired)

Many users have a good mobile connectivity experience, with over 70% saying the capabilities are as they expected, or it works well but could use some more features. A good portion of respondents still find mobile access lacking in capability or difficult to manage. Some write-in answers mentioned concerns about security, latency, and even safety.

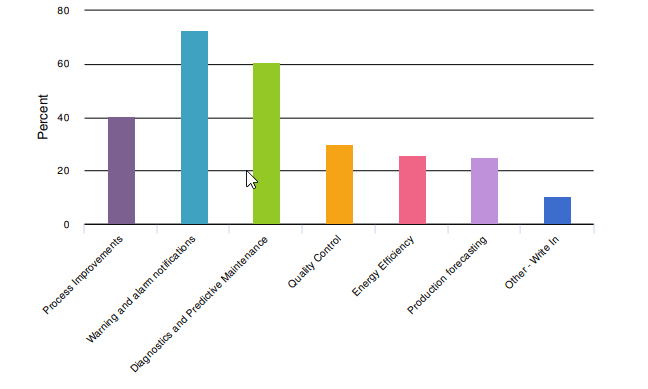

What main benefits and/or areas of improvement are you finding for mobile access? (select more than one if desired)

Users perceived the benefits of remote access as ranked in this order: warning and alarm notifications; diagnostics and predictive maintenance; process improvements; quality control; energy efficiency; and production forecasting. Some write-in benefits included convenience and flexibility.

A 10,000 Foot View

PLCs, HMIs, PCs, networking, cloud services, and mobile devices have undergone great improvements in the past few years. Automation is more capable and flexible than ever before. Connectivity in general, and mobile access in particular, can now be implemented in multiple ways. Many of these advances address the most important user concerns surrounding security, ease-of-use, and cost effectiveness. In summary, mobile connectivity for industrial systems is seeing increased adoption, and it appears this trend will continue.