Accessing actionable data is just as important as delivering reliable automation in some applications.

Damon Purvis, PLC Product Manager at AutomationDirect, wrote an article for the January 2022 issue of Control Engineering. The article is titled Getting Actionable Data from an ICS and it examines how for all types of industrial systems, accessing data is often as important as reliable automation.

Certainly, industrial users demand flawless functionality for machines and equipment, but they increasingly need to gather data from all types of industrial sources so they can view, analyze, and act upon it. Even though most PLCs, PACs, HMIs, and other automation devices are Ethernet-compatible, users must carefully consider which platforms will support current and future data management and security needs.

Connecting Data Producers with Consumers

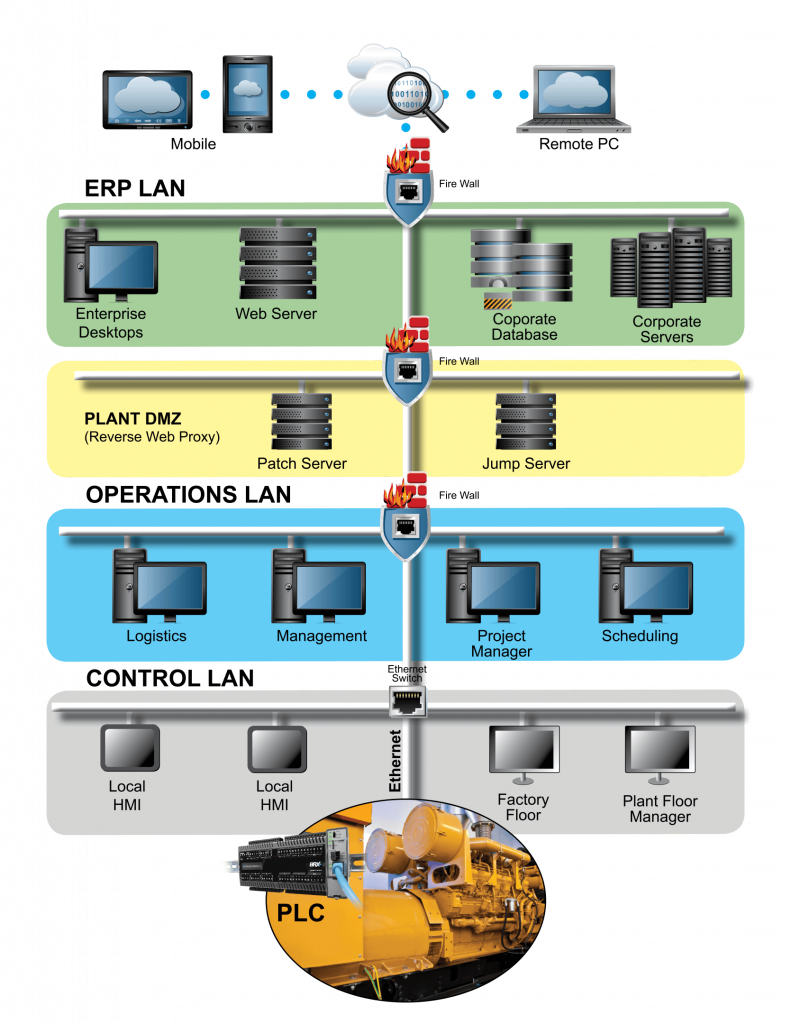

Traditionally, smaller systems have employed a PLC/PAC in the field, which communicates with a control room HMI or maybe a sitewide SCADA system, and perhaps higher-level enterprise systems. Today there are many more industrial data sources, and a wide variety of applications which need the data for delivering remote/mobile visualization, alarming, historizing, analytics, and more. IIoT solutions must securely connect producers and consumers of all vintages, and newer controllers speed and ease these efforts.

Structured Data Advantages

Unstructured data—which is typically individual raw numbers without any scaling, engineering units, or other helpful context—has long been typical for most industrial devices, and significant management effort is required to map and interpret it.

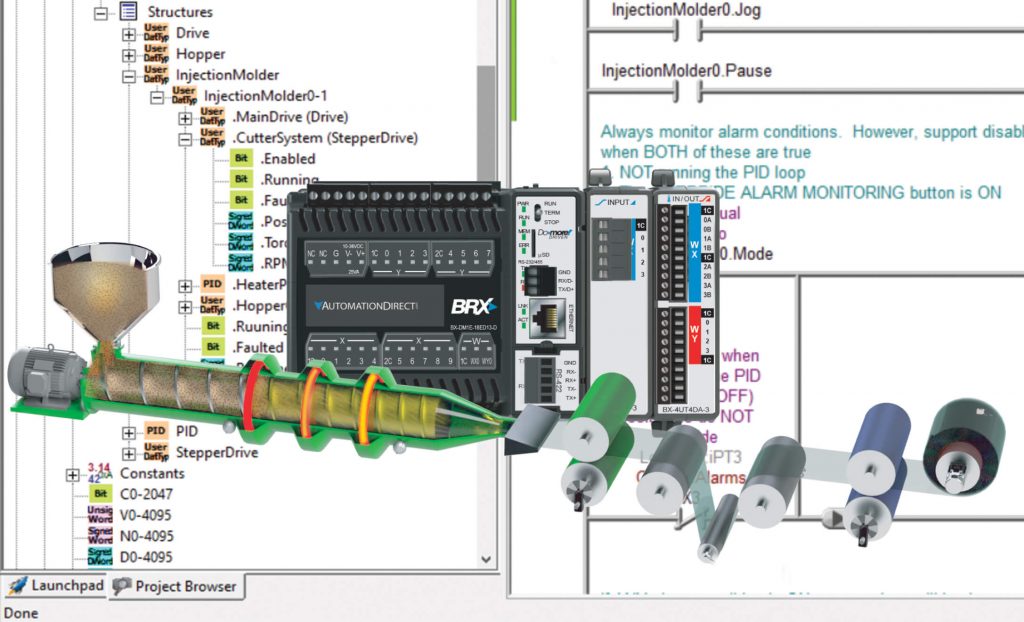

Newer PLCs, like the AutomationDirect BRX Series, support structured data, which embeds useful asset information in an organized and hierarchical manner. This enables structured data to span smoothly from the source machine PLC/PAC to any number of destinations, like HMIs, SCADA, historian, MES, ERP, and more.

Modern PLCs/PACs supporting structured data also enable client applications, which are usually associated with higher-level processing, to easily aggregate data, add enriching information, and compare results among similar assets worldwide.

PLCs/PACs can also take advantage of structured data as they gain better and more granular management options for defining data access and transmission. These capabilities will facilitate close integration of OT-based devices with IT-based security, and they will foster a growing and strong cooperative relationship between OT and IT groups.

Emphasizing Data Access and Security

Future PLCs/PACs will go beyond delivering reliable control of equipment and surviving harsh conditions. They will continue to do so but will also adopt new technologies.

The expectations of today’s sophisticated users, their need to incorporate advanced manufacturing methods, and the accelerating risk due to cybersecurity threats have combined to change the business-as-usual approach for future work.

Whether for new or retrofit projects, AutomationDirect offers a wide selection of products embracing modern IT open-source concepts, providing designers with the best solutions to meet for their data handling and security needs.