New PLCs gain capabilities to connect industrial-sourced OT data with higher-level IT and cloud-based systems.

Damon Purvis, PLC Product Manager at AutomationDirect, wrote a cover story article for the January 2021 issue of Control Engineering. The article is titled PLCs Power Industrial Data Integration and it looks at the many ways PLCs have gained enterprise data integration capabilities.

Not too long ago, the roles of industrial automation devices were relatively clear-cut. Simple sensors were wired to controllers, like PLCs, which in turn might be visualized by local HMIs. Today however there are many more options due to the availability of smart sensors, specialized controllers, and PLCs and HMIs with overlapping computing and communicating capabilities.

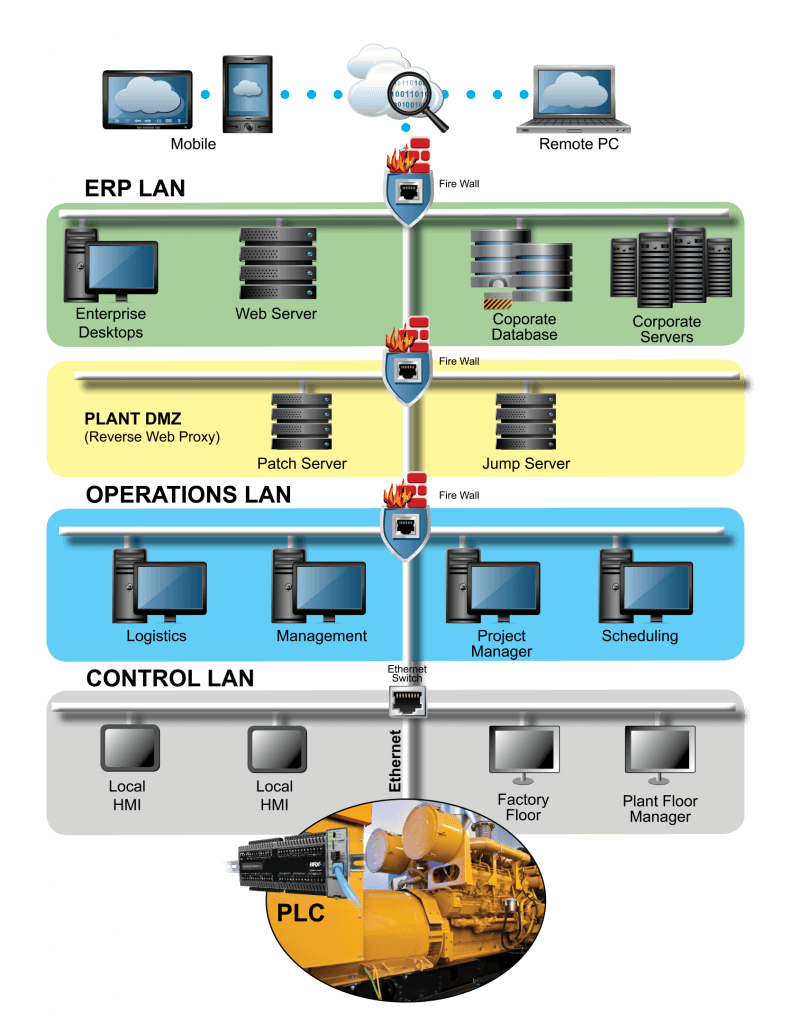

End users want to access the large amount of available internet of things (IoT) data to optimize operations. This means they need to transport data from the operational technology (OT) domain to the information technology (IT) world.

Traditional Connectivity Complications …

Classic PLCs were good for basic control but lacked advanced computation abilities, data structures, and the variety of communication protocols needed for IoT applications. Connectivity projects forced users to cobble together many layers of hardware and custom configurations, often lacking in terms of cybersecurity.

… Solved by Proficient PLCs

PLCs are already the reliable and established platform for edge automation tasks, but they have often used specialized programming environments and had limited abilities for providing IoT functionality. Vendors like AutomationDirect quickly realized that instead of creating a new type of IoT-capable device, they could enhance PLCs with more open capabilities so OT and IT end users could easily connect new and legacy factory equipment to enterprise systems and the cloud.

Integration Options

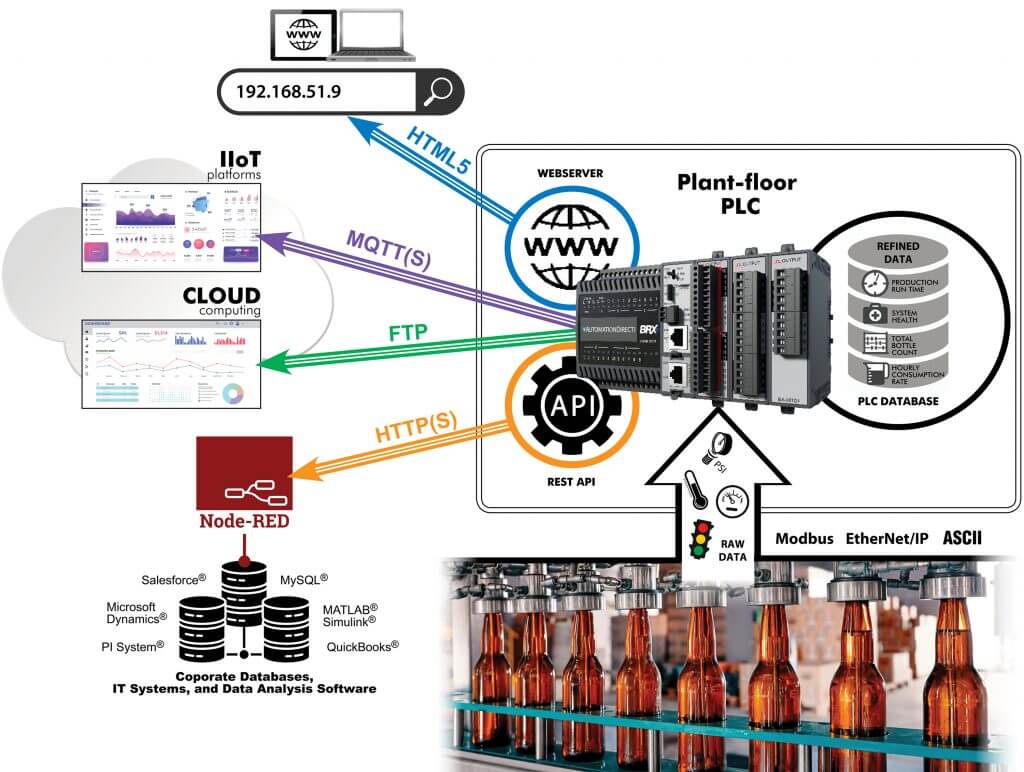

Next-generation PLCs, like the AutomationDirect BRX Series, are designed with features to enable seamless data integration. This includes popular serial and Ethernet OT and IT protocols like:

| OT | IT |

| ASCII | SNTP |

| Modbus RTU and TCP | DNS |

| K-Seq | MQTT |

| EtherNet/IP | SMTP |

| SSL | |

| Web services |

Many data integration methods which can be mixed and matched to best meet application requirements:

- Store data in the PLC and forward via FTP: Best for non-real-time bulk transactions.

- Web server: Free and useful for limited visualization of data on devices with proper privileges via the local network or internet.

- MQTT over TLS: Efficient, resilient, and secure way to transport data to site-located or cloud-based brokers, and to serve this information to clients anywhere.

- REST API: Enables authorized remote clients to request information. Polled data tags can be changed in the future without PLC modifications.

Built-In Security

With so many connectivity options, users must ensure cybersecurity measures are implemented. AutomationDirect PLCs offer the necessary features right out of the box.

Endless Applications

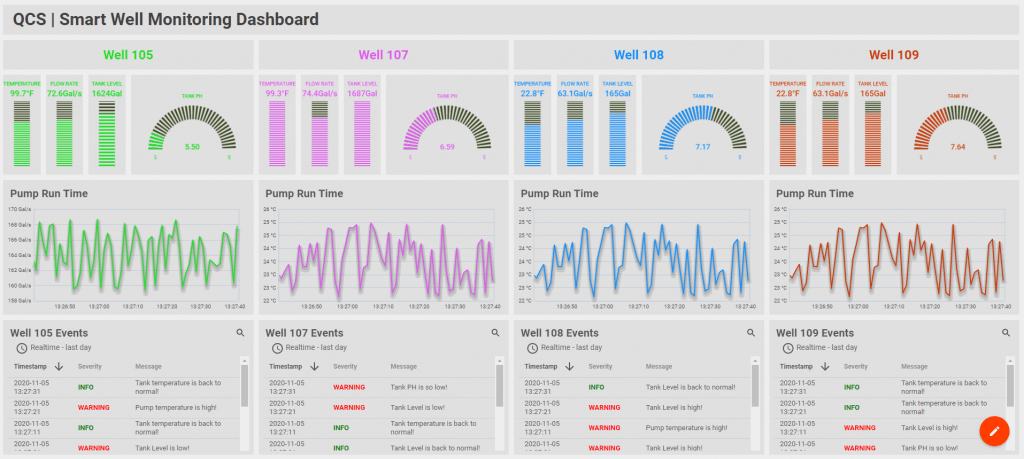

One solutions provider developed a cloud-based IoT application for monitoring remote sites. Modern PLCs, like the BRX with built-in MQTT, made it possible to directly connect this industrially-sourced data with higher-level computing and cloud-based systems.

PLCs Power OT to IT Connectivity

Yesterday’s OT automation devices were very specialized, but the latest PLCs have gained IT capabilities.

OT-based PLC technology is already well-proven in the field. The addition of IT-friendly protocols and security features to PLCs makes them ideal as edge devices for accessing raw field data using industrial protocols, processing it into information, and securely publishing or transmitting it to any industrial IoT client or external computing platform.

Read more articles about PLCS here!

Originally Published: January 2021