Even though Ethernet is a widely-adopted standard, there remains a great need to connect with commercial, industrial, and laboratory devices using enduring serial RS232/RS485 communication technology.

Chris Kregoski, product engineer for AutomationDirect, wrote an article for Industrial Equipment News September/October, titled Making Serial Connectivity Industrial-Grade. Here’s a summary, click on the link above for the full text.

Many of the latest digital devices use wired Ethernet or Wi-Fi, but there remain plenty of new and legacy devices that use long-established serial RS232/RS485 communications, sometimes as the only connectivity method. Serial communications may seem like “old tech,” but it is straightforward, inexpensive, and the right-sized digital interface for obtaining reasonable amounts of data at a sufficient speed.

Designers may be tempted to use hobby- or consumer-grade single board controllers to perform data aggregation tasks from one or more serial devices, but these light-duty components may not operate with the reliability required for industrial-grade applications, especially when installed in challenging environments.

To address this and other communication issues, AutomationDirect has developed the ProductivityOpen platform, with expandable Ethernet, serial, and wired I/O modules so users can apply a flexible open-source computing approach to industrial-grade serial/Ethernet communications and controls applications.

Developers work on many monitoring and control applications where they need to interact with multiple intelligent devices, such as VFDs, PID loop controllers, barcode scanners, lighting systems, analyzers, and more. Most of these devices are available natively with RS232 point-to-point (host to single device) or RS485 multi-drop (host to many devices), commonly using Modbus RTU or other protocols.

In recent years, many hobbyist “makers” have become familiar with creating “homebrew” projects using microcontrollers, such as the Raspberry Pi and Arduino. A standard Arduino seems attractive as a serial device aggregator because it can use stackable accessory boards, called shields, for Ethernet, Wi-Fi, serial, and other comm protocols. But these low-cost and bare-bones consumer-grade devices are not designed to withstand industrial-grade service, and often require modifications for mounting in enclosures and wiring to standard industrial devices.

The AutomationDirect ProductivityOpen Controller, on the other hand, is designed from the ground up using a ruggedized MKRZero Arduino and a tough housing to meet UL and other standards. It can accept standard shields, but it also connects with industrialized power supply, I/O, and other communications modules.

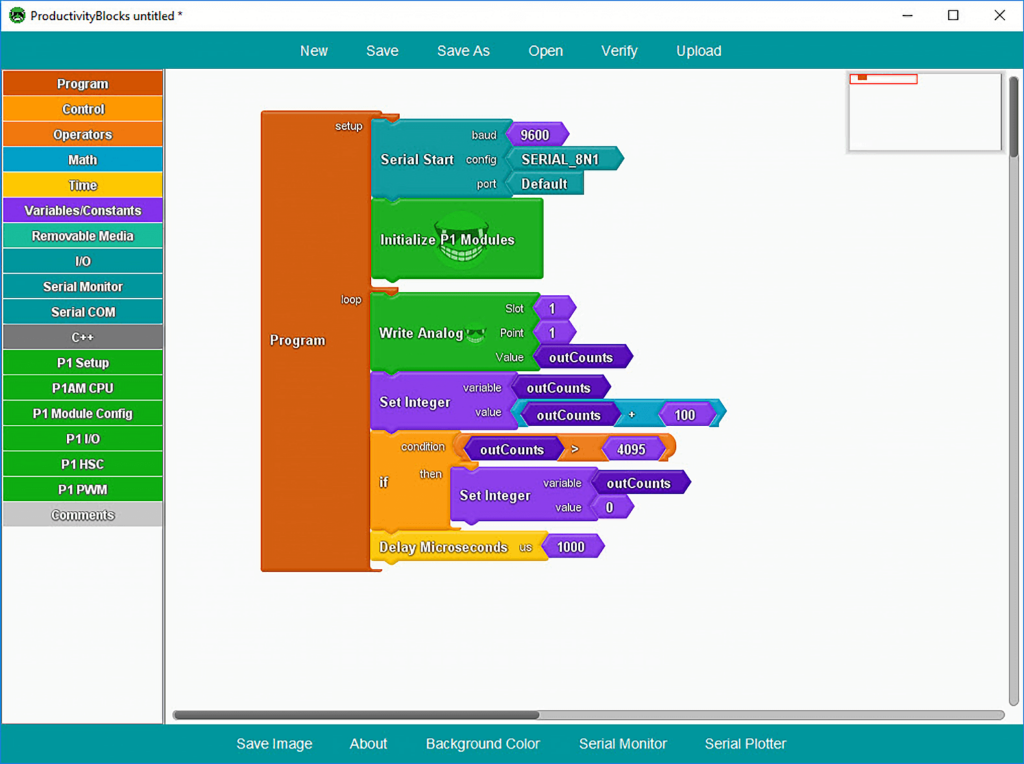

Users can be assured that the ProductivityOpen with a serial module provides a solid platform so they can develop whatever functionality is needed. They can use standard C++ and take advantage of code snippets available via GitHub, or use the free ProductivityBlocks graphical programming interface, or combine these and other programming languages and function blocks in a single application.

With this platform, the microcontroller can … consolidate the information and perform any needed calculations, and then send the results to the cloud over Ethernet via MQTT for data logging and alarming. The price for this complete hardware setup is around $200, which is more than hobbyist-grade products might cost. However, the resulting platform is clearly industrial-grade, and backed by an industry leading manufacturer with rapid online order fulfillment.

Check out the AutomationDirect website to find out more about the ProductivityOpen, and many other products providing industrial-grade solutions to meet your varied application needs.