In the early 1990s, many automation suppliers thought that using a direct catalog channel to offer automation products was too risky to attempt. There were concerns such as getting customers to buy from a company they couldn’t physically see, assisting them in selecting products, technical support, return and warranty issues and so on.

Because of these concerns, few automation suppliers wanted to risk the investment because they already enjoyed a large market share. To consider offering quality products at prices almost half of the industry average, free technical support, 30-day money-back guarantees, and in-stock

products with same day shipping, would have made most suppliers think twice. It would take far more than they were willing to give – especially when customers were buying their products already.

A few people didn’t see this as a risk, but as an opportunity, namely Tim Hohmann and Koyo Electronics. Tim knew that to create a company with the primary goal of serving the customer while offering quality products with pricing that would be too attractive to ignore required thinking outside the box. That is exactly what PLCDirect, now AutomationDirect, did when the company was founded over eleven years ago. Today, these same promises have remained the core reason for the success of AutomationDirect, a small PLC catalog company that turned into a successful automation superstore.

It’s no easy task to make such a large operation flow smoothly. With the hard work and dedication of several self-winding teams, AutomationDirect has developed a process to get a product from the manufacturer to the shelf and out the door to the end user as quickly and accurately as possible.

Finding the Right Products

Very few products fit our business model. We continually search for quality automation products designed with the latest features and technology while still allowing us to offer the low prices that our customers have learned to expect. Our name brand products come from companies such as Eaton Cutler-Hammer, Marathon Electric, Hubbell/Wiegmann, and Koyo Electronics of Japan, our parent company. We also private label many brands from companies who manufacture products for other leading automation suppliers. Our products must meet the expectations of our customers in relation to price, quality, features, and availability.

Finding products that fit all these requirements can be an arduous task, carried out by our teams of product managers in cooperation with product engineers. These teams are responsible for working with each product supplier to ensure they meet the AutomationDirect promise. Each product is tested to our standards, which includes compatibility with our existing products. To aid in determining the feasibility of a newly proposed product, several teams are included in the analysis to make sure it fits the AutomationDirect business model. The technical support team verifies that a product is user friendly, efficient to support, and that documentation and software may easily be applied by the customer. The product availability team fulfills our promise by making every effort to keep products available in our warehouse and ready for immediate shipping.

Making It Fit

The product management team is also responsible for working with each product supplier to ensure products are properly introduced into our business model without slowing down our well-oiled machine.

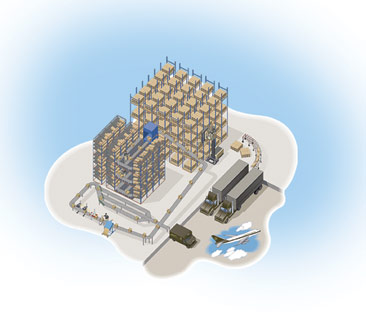

Since we stock most of our products, and ship customers’ orders the same day they are received, we try to adhere to strict packaging and inventory specifications. Our logistics team has set a goal of fulfilling 100% of the orders processed each day. For this reason, the team verifies that each product has proper bar-coding, package size, and part numbering. Each product is bar-coded so it can be tracked and delivered as quickly as possible to each station in the highly automated warehouse. Inventory must be stored in various locations and require as little manual handling as possible. Part numbers must be standardized for simplified labeling and processing. These are only a few of the specifications required for a product to be received from a manufacturer, placed into the warehouse system and shipped to the customer as quickly and efficiently as possible.

An enterprise-wide electronic order processing system in conjunction with an automated warehouse, which uses many of our own products for automation, allows us to take orders as late as 5 p.m. EST and ship the same day for products that are in stock.

Maintaining the Product

Once the product has been launched and is shipping to customers, product management works with each team to make sure the product continues to meet the expectations of the customer. In many cases, they receive direct feedback from customers on product functionality and requested enhancements. Occasionally, products will require firmware and software changes, as well as hardware changes, to introduce new or enhanced features. Product engineers work directly with the product supplier to make changes as quickly and accurately as possible. If while working with a supplier, we find they cannot conform to our customers’ needs, we will search to find a new supplier that can. In this case, we work to make sure the product is as backward-compatible as possible with the product it replaces.

Case In Point

AutomationDirect is committed to offering automation products that deliver the latest features and quality that our customers need for their applications. In the case of our legacy operator interface product line, the market was changing and the features and quality of the product line were not meeting our customers’ expectations or needs. As such, we realized we would have to turn to a new operator panel supplier. We needed a manufacturer with a history of designing and manufacturing quality products with the ability to respond to our customer needs for continual improvements. This is why we chose our parent company, Koyo Electronics, to design and build the panel that would take us to the next level with our HMI product – C-more.

With Koyo as the designer and manufacturer, we have access to hardware and software engineers that help support the product and willingly make requested changes and improvements. We knew that Koyo could create a product that would offer the best combination of quality, features, and price. We asked them for an outstanding product. We received that and much more.

With Koyo as the designer and manufacturer, we have access to hardware and software engineers that help support the product and willingly make requested changes and improvements. We knew that Koyo could create a product that would offer the best combination of quality, features, and price. We asked them for an outstanding product. We received that and much more.

C-more was designed to give our customers one of the best costs of ownership when considering the initial price, features, ease of use, reliability and technical service. We started with a completely new design, and now have an operator panel that is more durable, with better performance, and more built-in communications options than our previous panel. We added extra interface features such as USB ports, CompactFlash slots, and an audio output for amplified speakers. We expanded to 10 or 40 MB of memory for those applications that require larger projects. Certain C-more panels offer built-in Ethernet communications with the ability to send event-driven e-mail or FTP a file to another computer on the network in HTML format.

If you are wondering why we chose a name like C-more for this new product line, it’s simple. Once we saw all the features of the C-more panels, we began to realize that this newly designed panel had hundreds of improvements over our legacy operator interface line. Our customers would see more hardware reliability, see more features, see more color, see more productivity, and see more savings. C-more seemed to be the perfect name.

An important feature of the C-more product line is the ability for the C-more software to convert EZ-Touch programs from their legacy format to C-more format, which preserves the customer’s work on their application, and allows them to get the latest technology without re-writing their program. Also, C-more was designed to be mechanically interchangeable (including cables) with equivalent EZTouch models.

So whether we are bringing on an entirely new product line, such as the C-more panel, or one as simple as a new sensor, it takes teamwork and a multitude of tasks to get the product to our customers with the AutomationDirect promise of quality, features, price, delivery and service.

By Greg Philbrook,

AutomationDirect Product Manager

Originally Published: March 1, 2006